Improved spray gun for die casting

An improved, spray gun technology, applied in the direction of cleaning methods using tools, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of the release agent mixed with impurities, the clogging of pipes and spray holes, and the influence of the spray process. Improve purification efficiency, safe and convenient use, and avoid the effect of reducing the amount of spray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

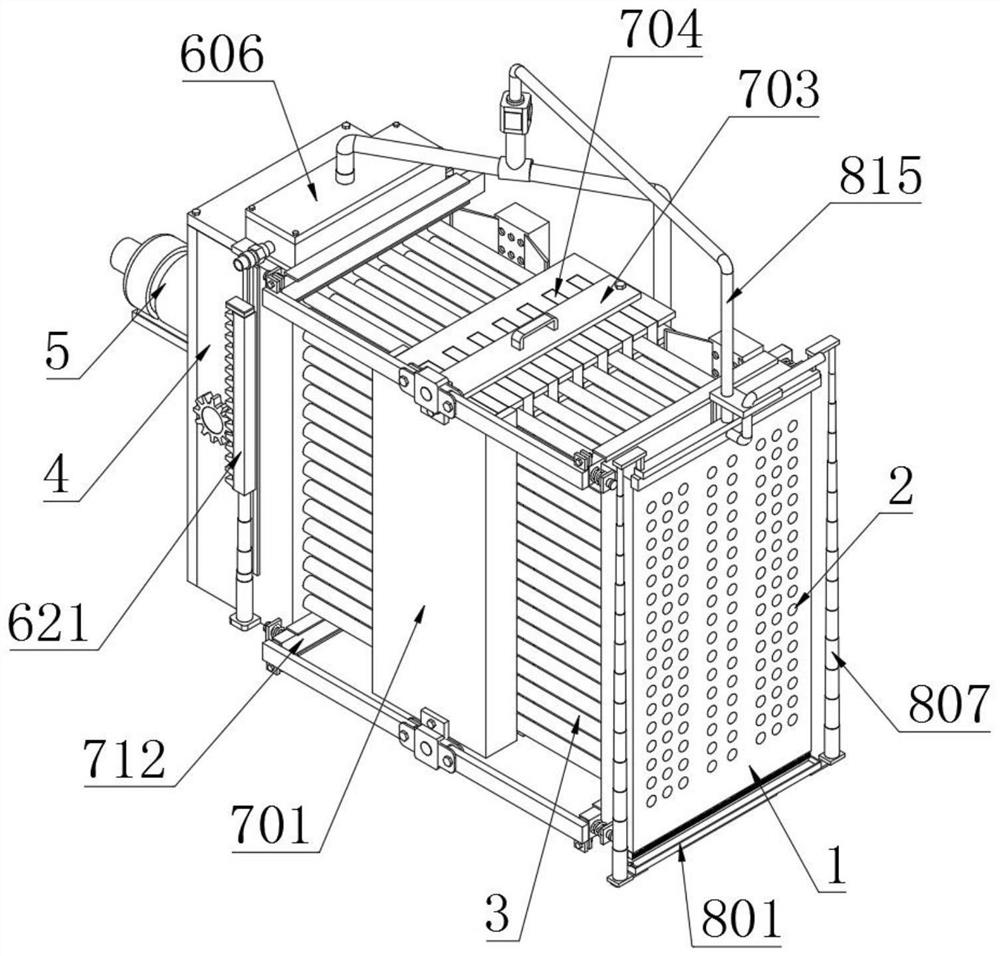

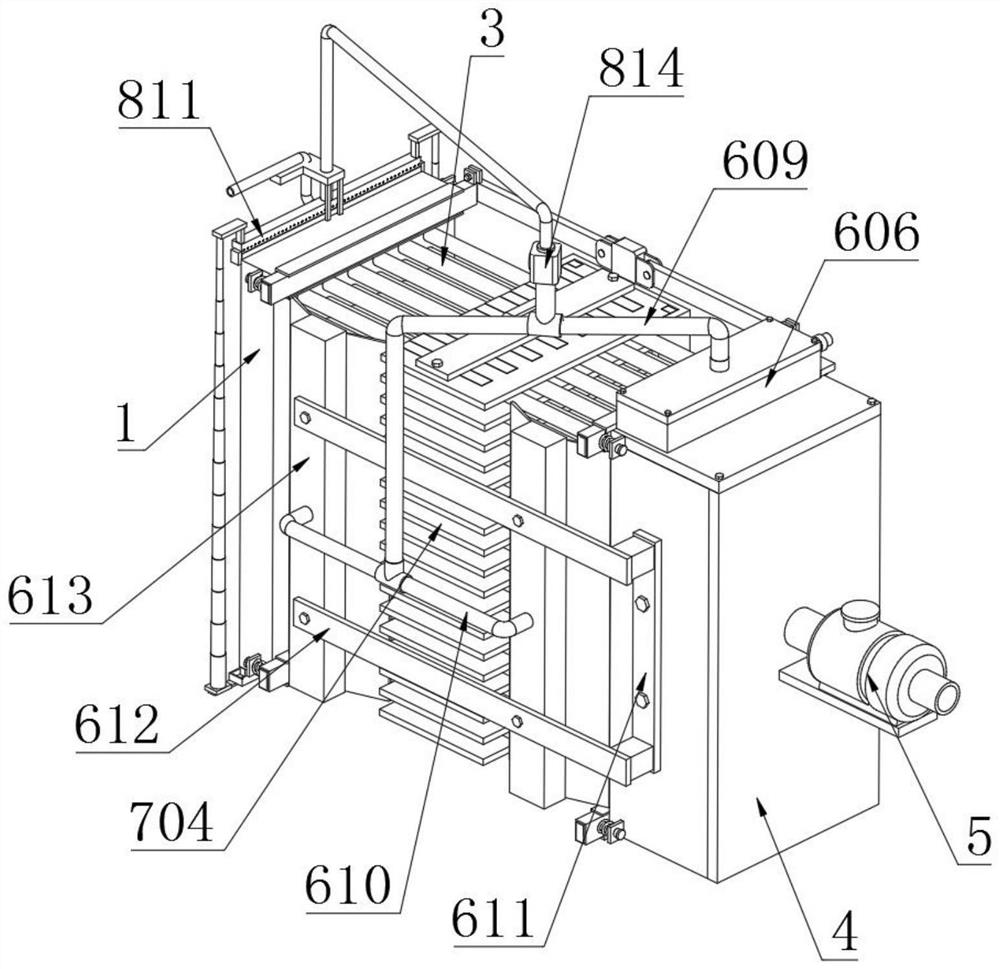

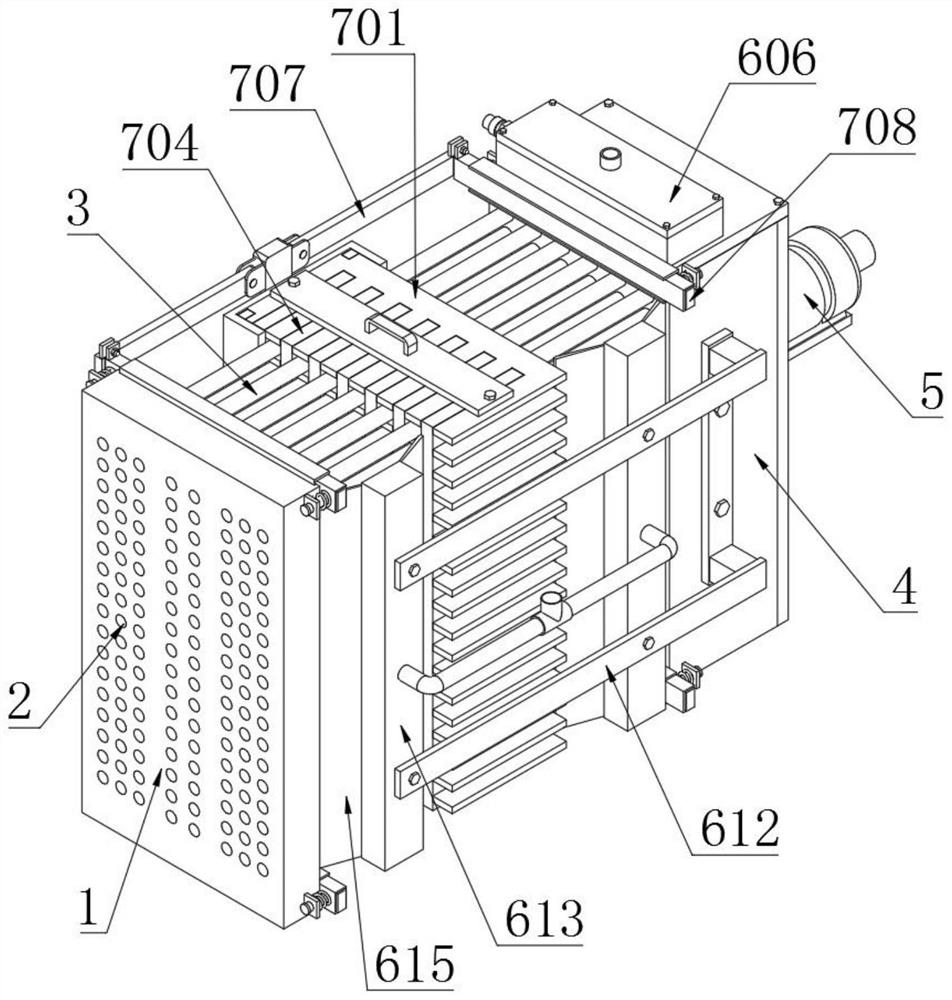

[0035] Example: such as Figure 1-9 As shown, the present invention provides a technical solution, an improved spray gun for die-casting, comprising a spray gun plate 1, the end of the spray gun plate 1 is provided with a spray hole 2, and the inner side of the spray gun plate 1 is fixedly connected with a spray steel pipe 3, spraying The number of steel pipes 3 is 102, and the number of spray steel pipes 3 increases, which effectively increases the amount of spraying, making the spraying amount of the mold more uniform, and increasing the number will not affect the spray flow rate, shortens the product production cycle time, and improves work efficiency. One end of the steel pipe 3 is fixedly connected with a transfer box 4, and one end of the middle part of the transfer box 4 is fixedly installed with a delivery pump 5, and the interior of the transfer box 4 is provided with a purification and anti-blocking mechanism 6 to purify and filter the transported release agent. Ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com