Welding wire conveying channel reinforcing device special for gas metal arc welding equipment

A conveying channel and reinforcing device technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of high difficulty, poor feasibility and high cost, and achieve the effects of excellent manufacturing characteristics, high reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

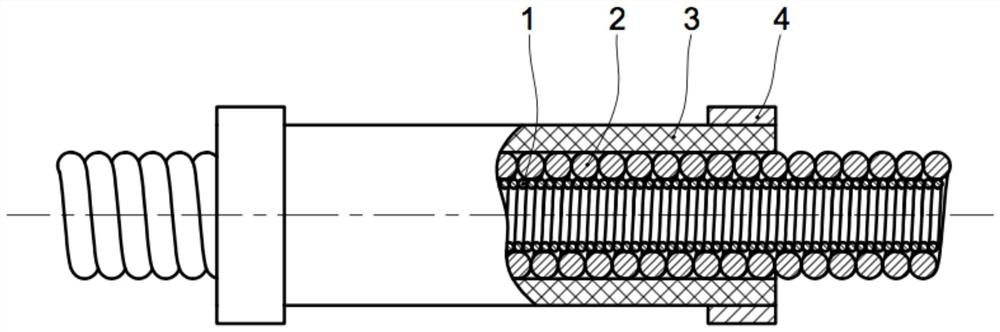

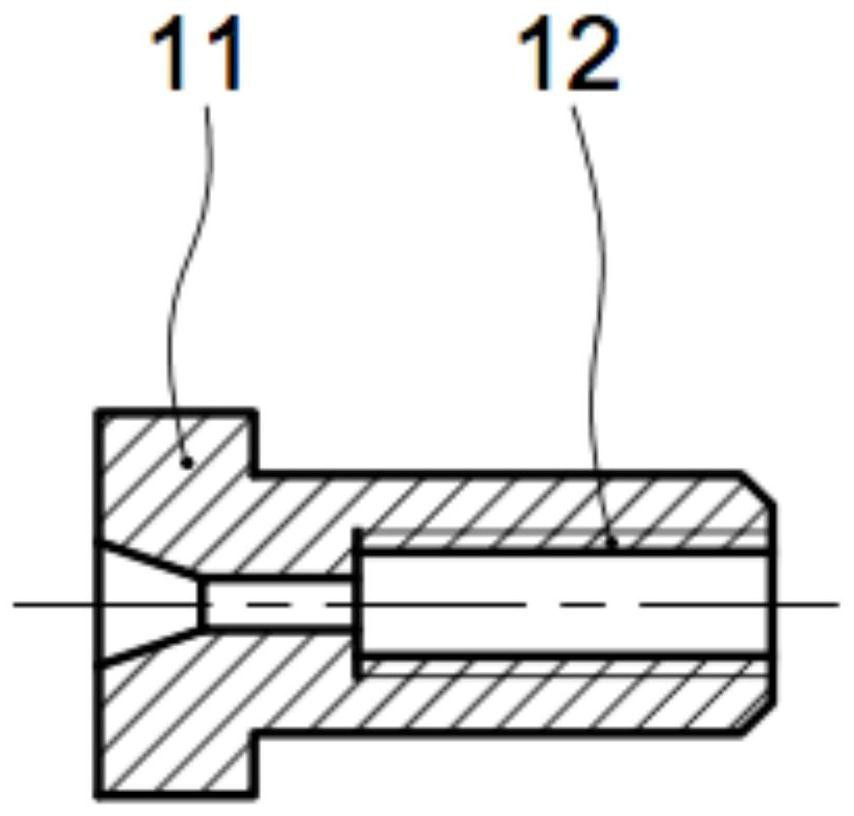

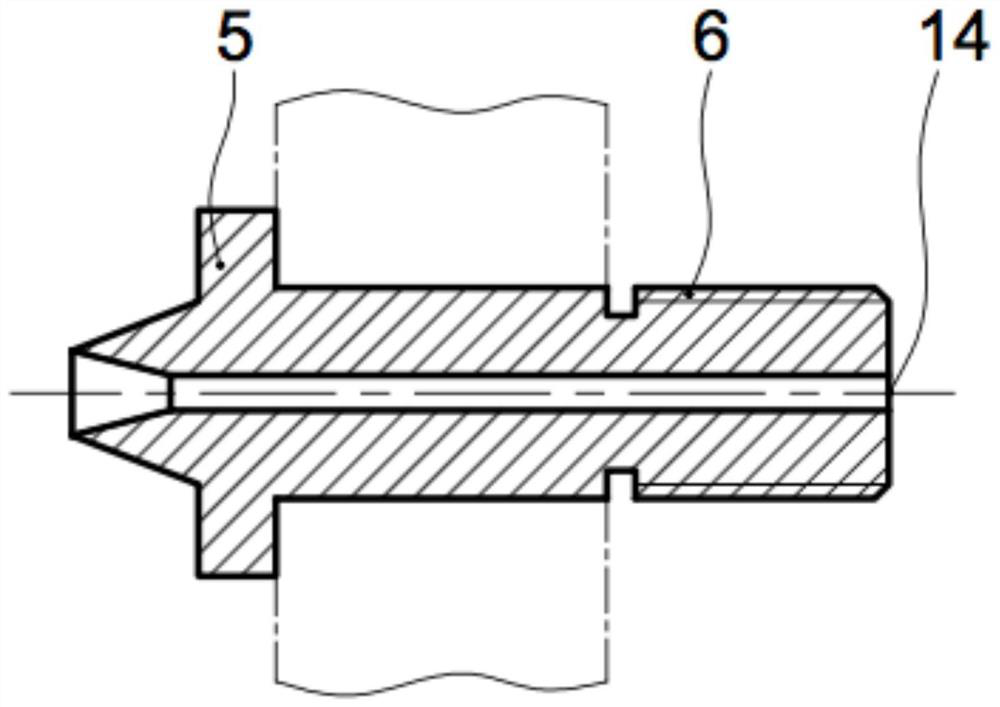

[0040] figure 1 A schematic diagram of the reinforcement device of the wire conveying channel of the special MIG / MAG welding equipment of the present invention is shown. The welding wire conveying channel reinforcement device includes a reinforcement inner pipe 1, a reinforcement outer pipe 2, an insulating jacket 3, a throat hoop 4, a wire feed joint 5, an anti-displacement joint 11 and an outer pipe seat. The reinforced inner pipe 1, the reinforced outer pipe 2, and the insulating jacket 3 are nested in sequence from the inside to the outside and then fastened by the throat hoop 4. The outer tube seat includes a wire inlet end outer tube seat 7 and a wire outlet end outer tube seat 13 .

[0041] The reinforced inner tube 1 does not need to be customized, and the wire spring hose is modified (only the required length is intercepted). The outer diameter of the wire spring hose should be determined according to the inner diameter of the designed reinforced outer tube 2.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap