Construction method for large-dip-angle giant steel pipe column core tube penetrating through basement top plate

A basement roof and steel pipe column technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of long occupation time, high cost, and large material consumption, and achieve the effects of reasonable organization, easy adjustment, and improved predictability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

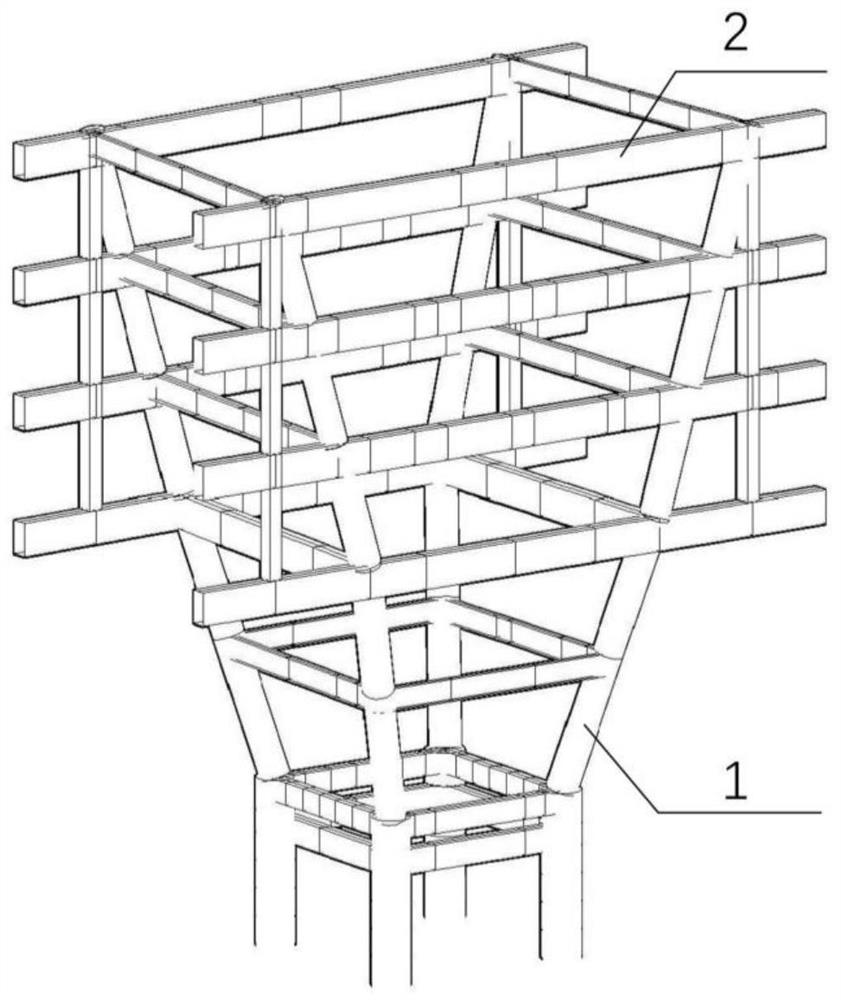

[0033] see figure 2 , a giant steel pipe column core tube with a large inclination angle, adopts a bottle-shaped support system with the bottom contracted and the upper part expanded, and is composed of 4 steel pipe columns 1 and steel box girders 2 between the columns. Each steel pipe column 1 weighs 70 tons and is multi-angle The special-shaped members of the space, the section form of the steel box girder between the columns is a parallelogram, which is a long-span super-heavy steel box girder. The spatial positioning of the core tube is difficult, and the installation error is immeasurable.

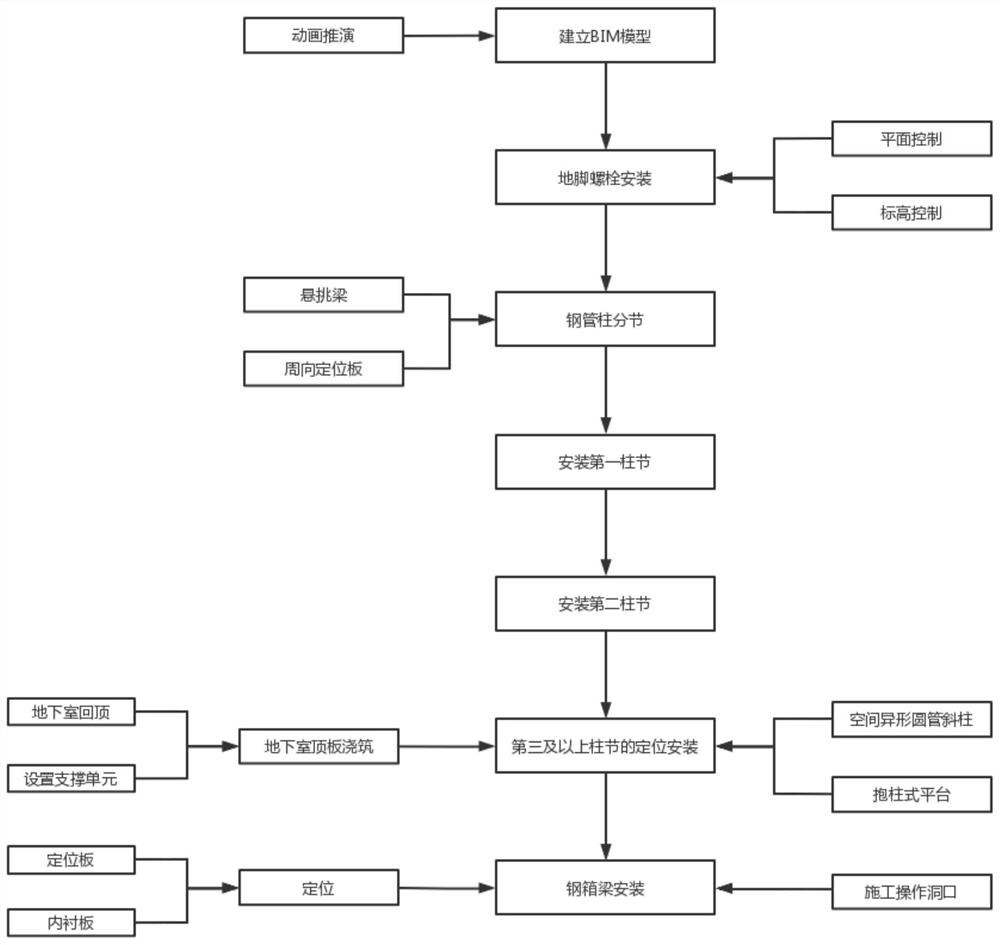

[0034] see figure 1 , the present invention provides a construction method of a giant steel pipe column core tube with a large inclination angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com