Mounting support capable of rapidly and manually adjusting rigidity and damping and rigidity adjusting method

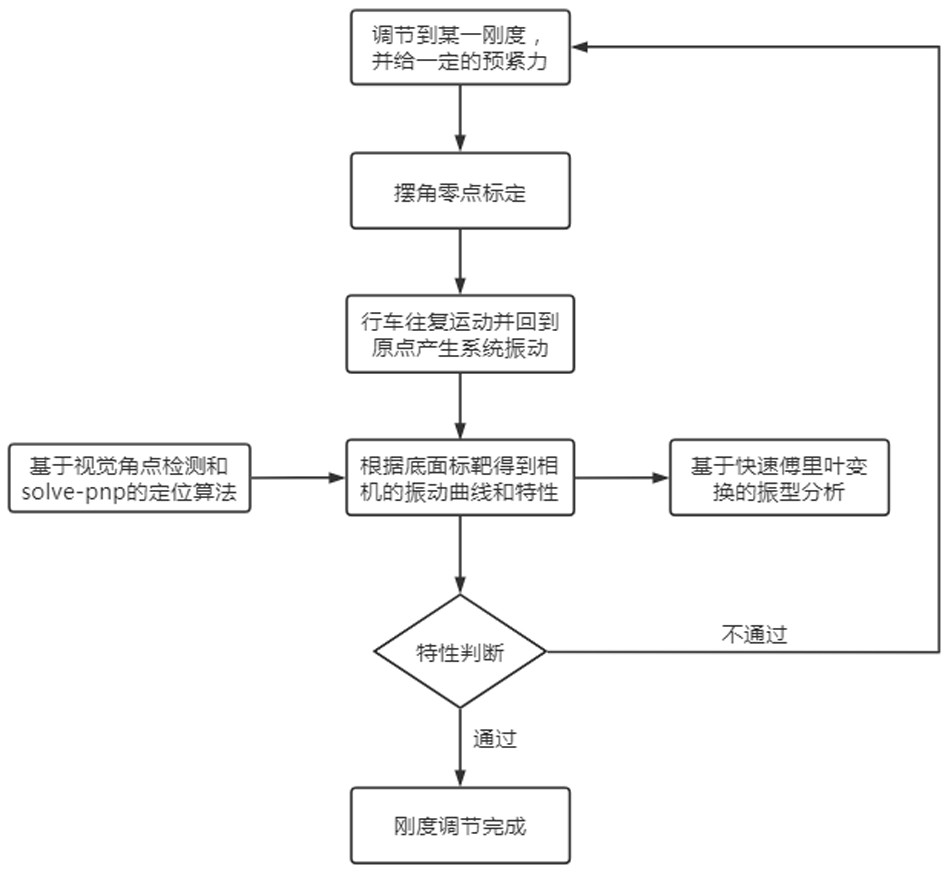

A technology of mounting support and manual adjustment, applied in transportation and packaging, vibration suppression adjustment, camera body and other directions, can solve the problems of reducing installation and debugging efficiency, time-consuming replacement of rubber pads, etc., and achieves simple structure and high reliability. , the effect of low-frequency vibration elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

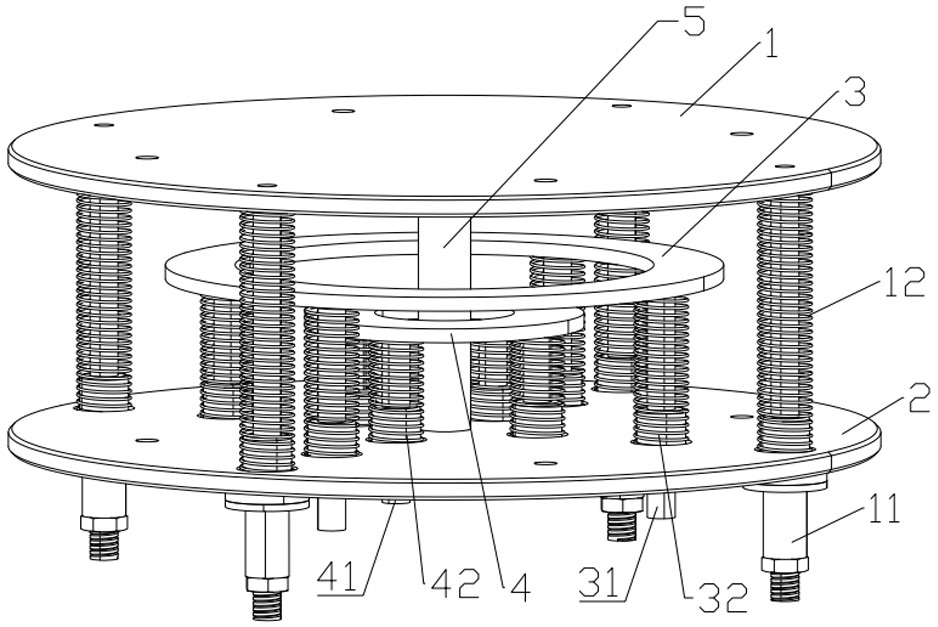

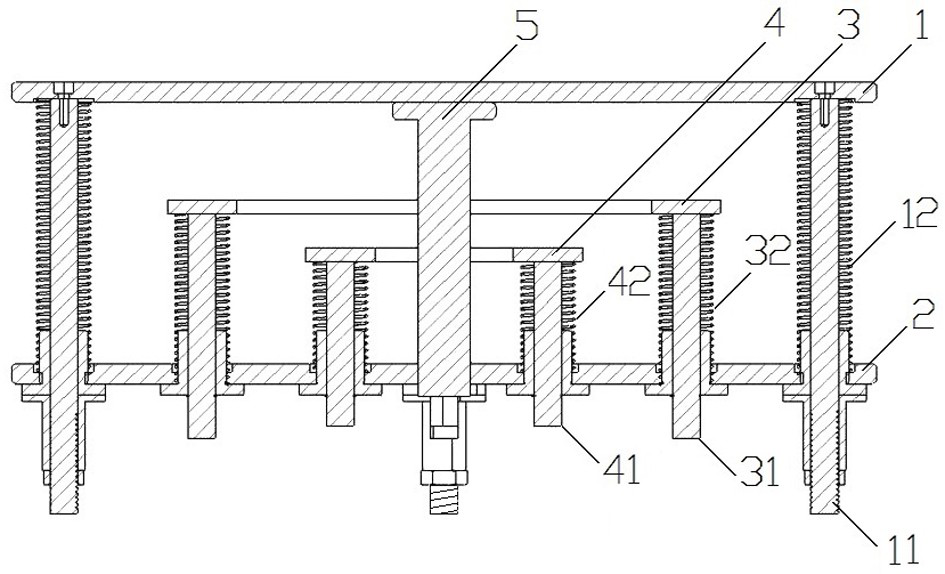

[0028] like Figure 1-2 As shown, the present invention provides a mounting support for quick manual adjustment of stiffness and damping, including a reference plate 1 above and a fixed plate 2 below, the reference plate 1 and the fixed plate 2 are arranged in a circle and parallel; the damper One end of 5 passes through the bottom of the fixed plate 2 from the lower center position and is fixed on the bottom center of the reference plate 1, and the opposite end is locked below the fixed plate 2. There are also four first guide bolts 11 arranged b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com