Dual-drive forward and reverse gearbox

A dual-drive, gearbox technology, applied to transmission parts, transmission control, instruments, etc., can solve the problems of complex structure of gearbox, unfavorable manufacturing and maintenance, etc., to facilitate fault finding and maintenance, reduce steering radius, The effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

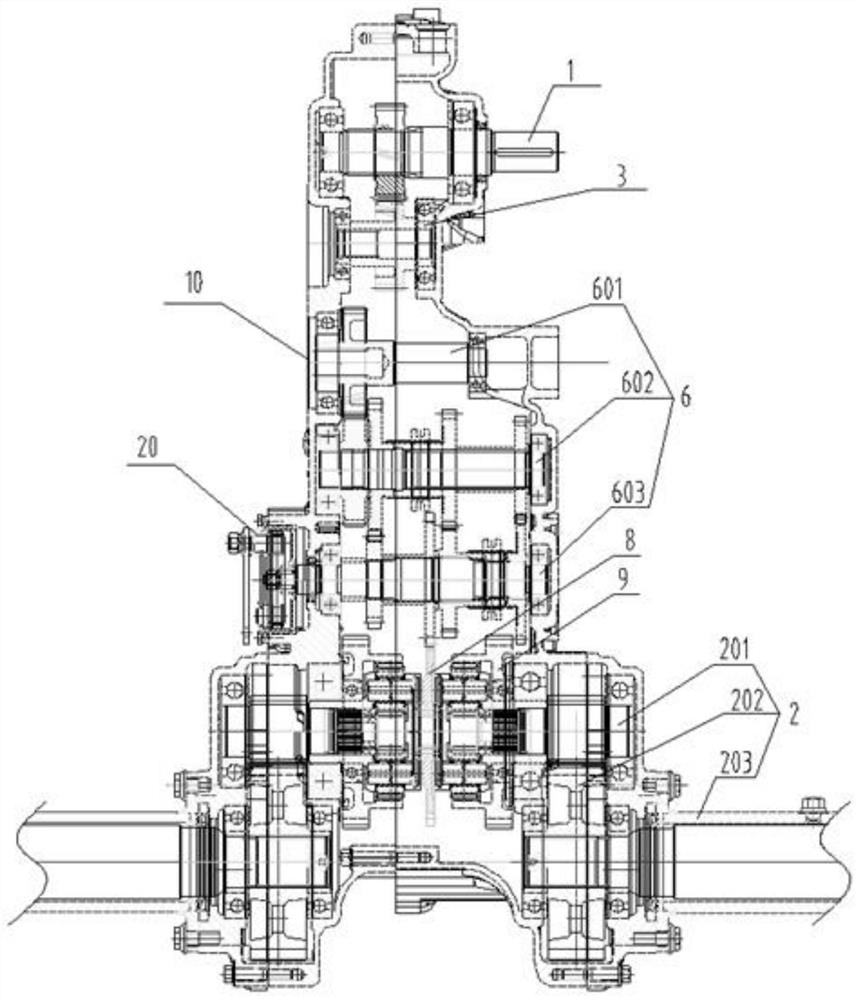

[0042] In this application, the terms "upper", "lower", "left", "right", "front", "rear", "top", "bottom", "inner", "outer", "middle", The orientations or positional relationships indicated by "vertical", "horizontal", "horizontal", and "longitudinal" are based on the orientations or positional relationships shown in the drawings. These terms are mainly used to better describe the present invention and its embodiments, and are not intended to limit that the indicated device, element or component must have a specific orientation, or be constructed and operated in a specific orientation.

[0043] In order to enable those skilled in the art to better understand the solution of the present application, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

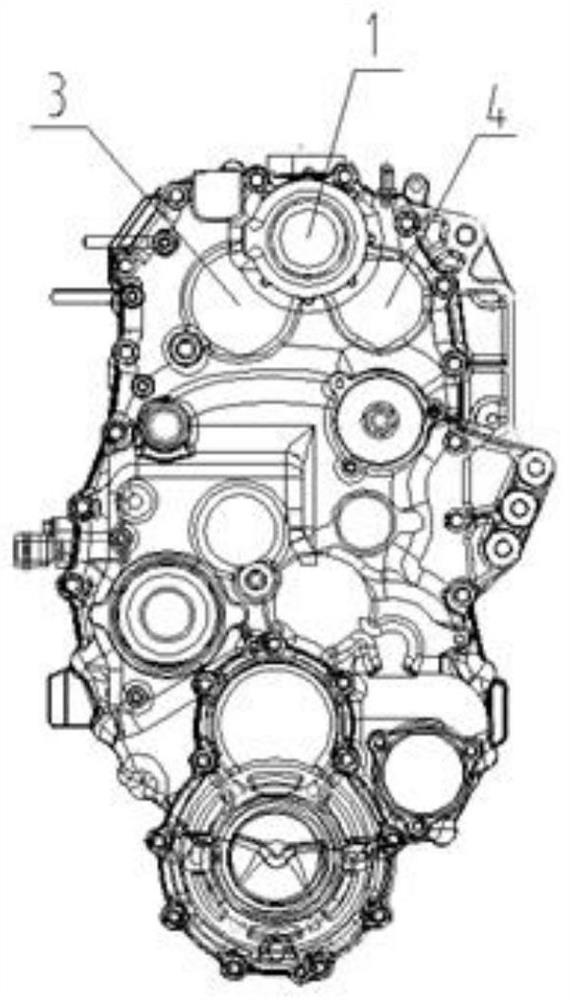

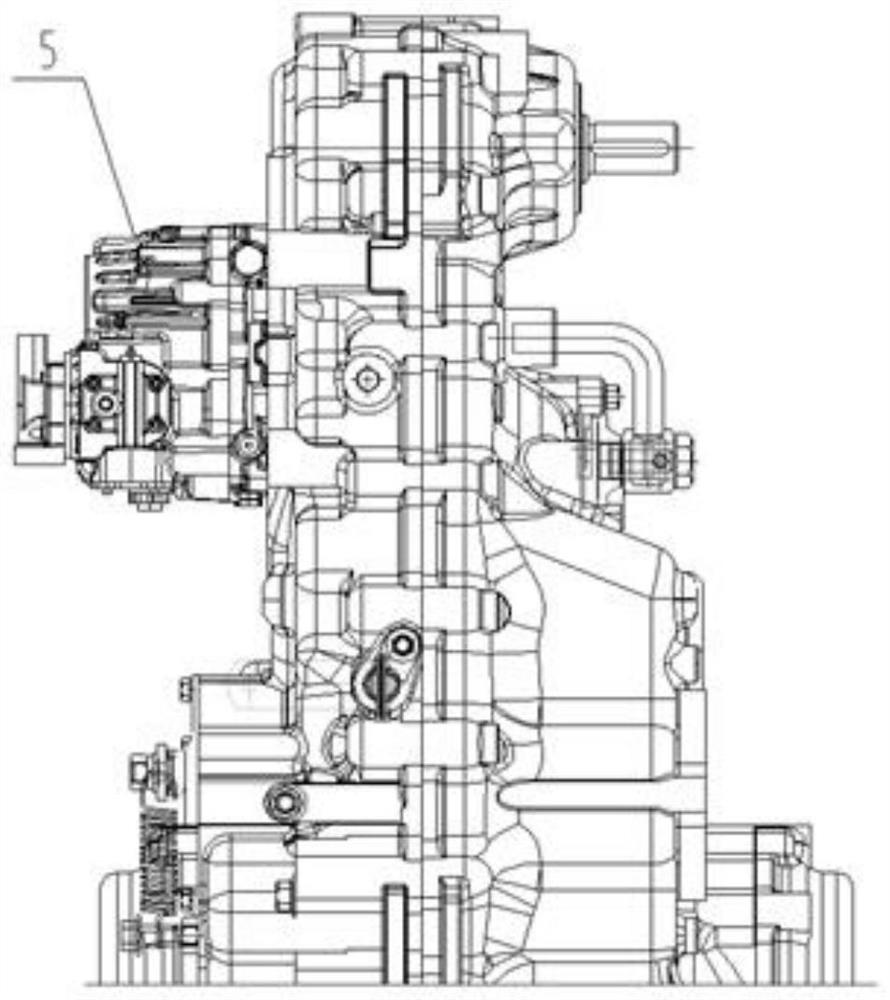

[0044] like Figure 1-Figure 22 It shows a dual-drive forward and reverse gearbox, including a box body, a main power shaft assembly 1, two output shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com