Self-service equipment maintenance indication method and system based on AR (Augmented Reality) technology and medium

A self-service equipment, AR technology, applied in 3D image processing, image data processing, instruments, etc., can solve problems such as affecting user experience, reducing equipment maintenance efficiency, and low information sharing, achieving easy operation and learning, improving The effect of equipment maintenance efficiency and user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

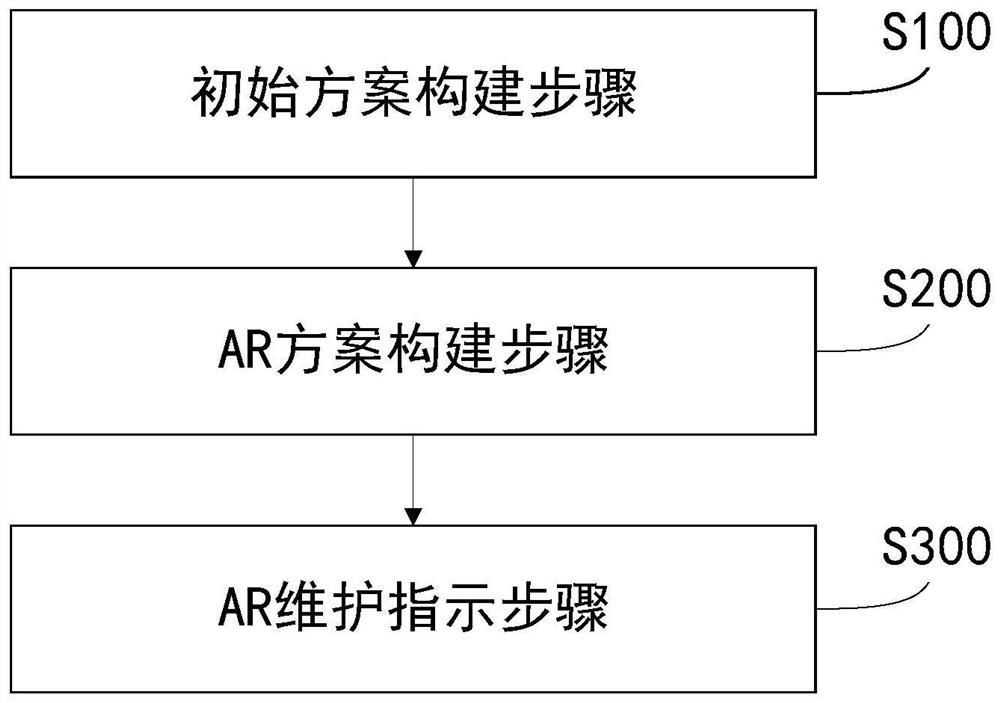

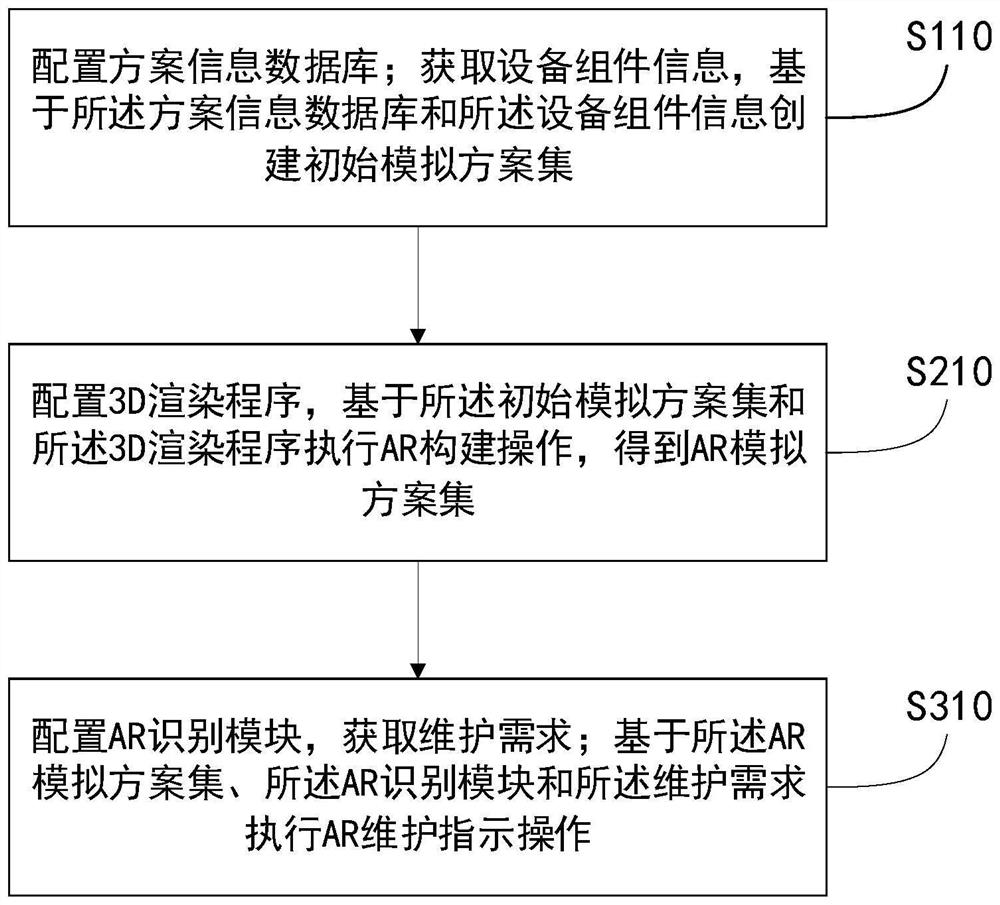

[0056] This embodiment provides a self-service device maintenance instruction method based on AR technology, such as figure 1 and figure 2 shown, including the following steps:

[0057] S100. Steps for constructing an initial scheme, specifically including:

[0058] S110. Configure the scheme information database; obtain equipment component information, and create an initial simulation scheme set based on the scheme information database and the equipment component information; in this embodiment, step S100 is used as the initial configuration of the scheme, and is step S200 and step S300 Provide data basis;

[0059] Specifically, the scheme information database is configured with several scheme packages; each scheme package is configured with different component pictures, several kinds of historical fault information matching the component picture, and several historical fault information matching respectively. A number of solution information; the equipment component info...

Embodiment 2

[0086] This embodiment is based on the same inventive concept as the self-service equipment maintenance indication method based on AR technology described in Embodiment 1, and further provides an AR technology-based self-service equipment maintenance indication system, such as image 3 As shown, including: initial scheme building block, AR scheme building block and AR maintenance indication module;

[0087] In the self-service equipment maintenance instruction system based on AR technology, the initial scheme construction module is used to configure the scheme information database; the initial scheme construction module acquires equipment component information, and creates an initial scheme based on the scheme information database and the equipment component information. set of simulation scenarios;

[0088] Specifically, the scheme information database is configured with several scheme packages; the scheme package is configured with component pictures, some historical fault i...

Embodiment 3

[0101] This embodiment provides a computer-readable storage medium, including:

[0102] The storage medium is used to store the computer software instructions used to implement the self-service device maintenance instruction method based on AR technology described in Embodiment 1 above, which includes instructions for executing the above-mentioned self-service device maintenance instruction method based on AR technology. set program; specifically, the executable program can be built into the AR technology-based self-service equipment maintenance instruction system described in Embodiment 2, so that the AR technology-based self-service equipment maintenance instruction system can execute the built-in executable program The program implements the self-service device maintenance instruction method based on AR technology described in Embodiment 1.

[0103] In addition, the computer-readable storage medium in this embodiment may use any combination of one or more readable storage m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com