Self-breakdown gas switch and pulse power device

A gas switch and self-breakdown technology, which is applied in the direction of electrical components, spark gaps, and spark gap components, can solve the problems that affect the output pulse waveform stability, large voltage dispersion and randomness of pulse power devices, and achieve increased The effect of local electric field strength, improving stability, and promoting discharge conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

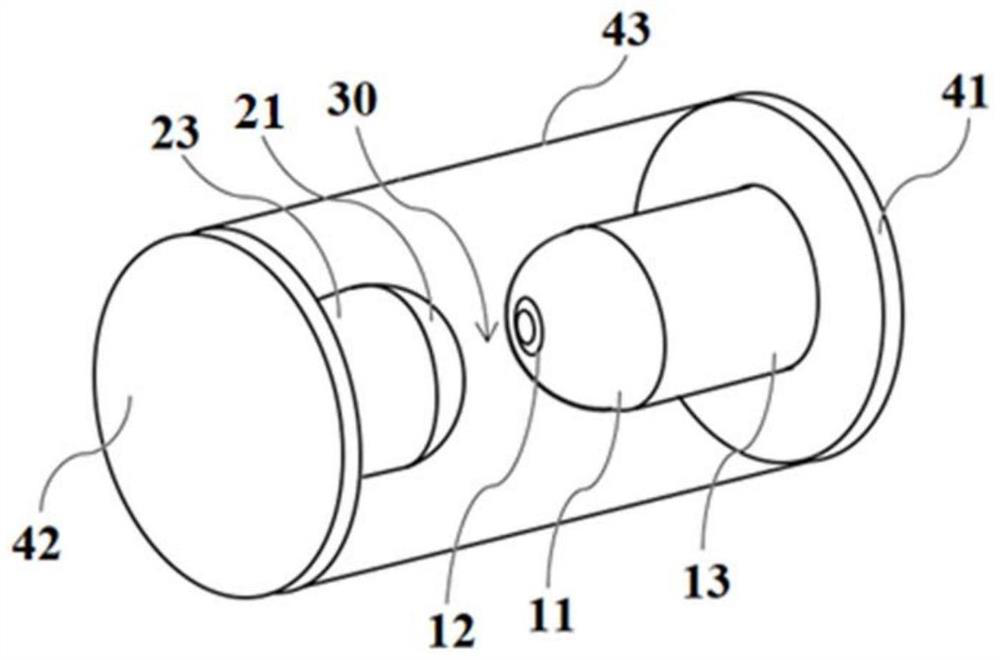

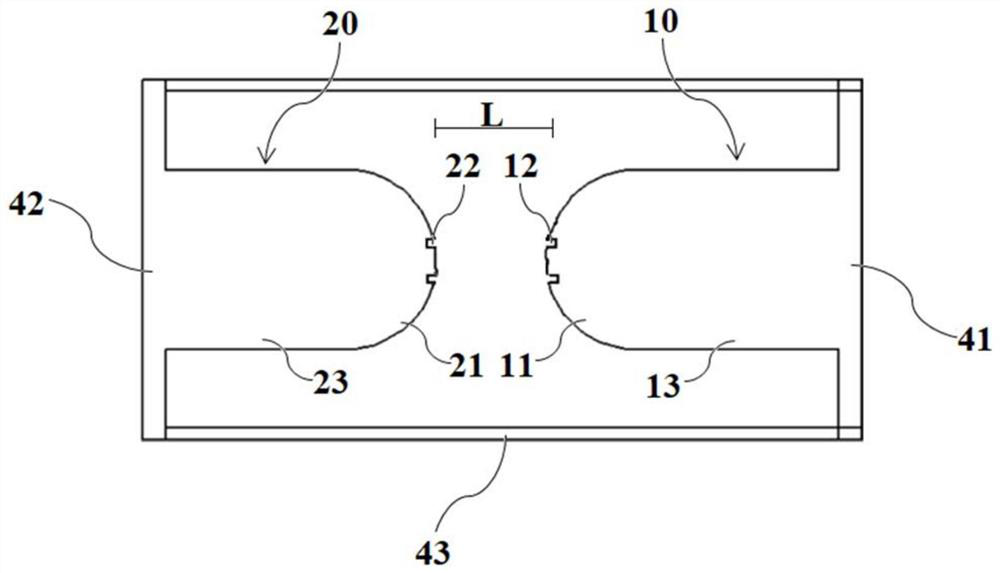

[0074] A self-breakdown gas switch includes a first electrode 10, a second electrode 20 and a casing, and the first electrode 10 and the second electrode 20 are arranged in the casing. The shell is a cylinder and includes a first bottom surface 41 , a second bottom surface 42 and a side wall 43 . The bottom diameters of the first bottom surface 41 and the second bottom surface 42 are 100 mm.

[0075] The first electrode 10 includes a first end portion 11 and a first cylinder 13 . The first end 11 is a hemisphere (1 / 2 sphere), one bottom surface of the first cylinder 13 is connected to the bottom surface of the hemisphere, and the other bottom surface is connected to the first bottom surface 41 of the casing. The diameter of the bottom surface of the hemisphere is equal to the diameter of the bottom surface of the first cylinder 13 , and the hemisphere and the first cylinder 13 have the same axis. An annular first groove 12 is formed on the top of the hemisphere at the first ...

Embodiment 2

[0081] The structure of the self-breakdown gas switch of this embodiment is the same as that of the self-breakdown gas switch of Embodiment 1, the only difference is that: no hemispherical first end 11 and second end 21, first groove 12, The second groove 22 is offered on the bottom surface of the first cylinder 13 and the second cylinder 23 respectively, and the distance between the bottom surface of the first cylinder 13 and the bottom surface of the second cylinder 23 provided with the groove is 10mm (that is, the gap 30 The length L is 10 mm). After testing, the breakdown jitter in this embodiment is about 5%.

Embodiment 3

[0083] The structure of the self-breakdown gas switch of this embodiment is the same as the self-breakdown gas switch of Embodiment 1, the only difference is that the outer diameter of the first groove 12 is 10 mm, and the outer diameter of the second groove 22 is 10 mm. After testing, the breakdown jitter in this embodiment is about 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com