Method for improving quality of cigar tobacco leaves through cocoa medium fermentation

A technology of cigar tobacco leaves and quality, which is applied in the fields of tobacco, application, and treatment of tobacco to achieve the effect of improving aftertaste, increasing flavor and quality, and weakening miscellaneous gas and irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

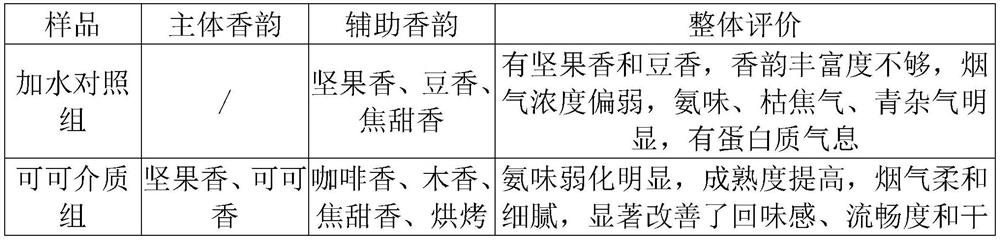

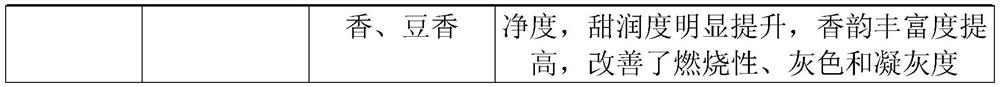

[0022] Prepare 300g of Dexue No. 4 upper grade 1 cigar leaves, mix 0.9g of cocoa powder and 44.1mL of deionized water evenly to prepare a cocoa medium solution, spray the cocoa medium solution evenly on the surface of the cigar leaves above, and then put the tobacco leaves into the sackcloth bag. Put the burlap bag into a constant temperature and humidity incubator for fermentation, the fermentation conditions are: the fermentation humidity is 75%, the temperature is 35°C, and the fermentation period is 30 days. After the fermentation, the water balance was carried out until the moisture content of the tobacco leaves was 20±1%, and then the sensory evaluation and aroma component testing of the cigar samples were carried out. The results are shown in Table 1 and Table 2.

[0023] In addition, the cocoa medium solution was replaced with pure water, and the blank control group experiment was carried out according to the same procedure.

[0024] The sensory quality evaluation met...

Embodiment 2

[0035] Prepare 300 g of Dexue No. 7 upper grade 1 cigar leaves, stir 0.9 g of cocoa powder and 44.1 mL of deionized water to prepare a cocoa medium solution, spray the cocoa medium solution evenly on the surface of the cigar leaves, and then put them into a burlap bag. Put the burlap bag into a constant temperature and humidity incubator for fermentation, the fermentation conditions are: the fermentation humidity is 75%, the temperature is 35°C, and the fermentation period is 30 days. After the fermentation, the water balance was carried out until the moisture content of the tobacco leaves was 20±1%, and then the sensory evaluation and aroma component testing of the cigar samples were carried out. The results are shown in Table 3 and Table 4.

[0036] In addition, the cocoa medium solution was replaced with pure water, and the blank control group experiment was carried out according to the same procedure.

[0037] Table 3 The effect of cocoa medium on the sensory quality of De...

Embodiment 3

[0044] Prepare 300g of Chuxue-14 upper grade 1 cigar leaves, mix 0.9g of cocoa powder and 44.1mL of deionized water evenly to prepare a cocoa medium solution, spray the cocoa medium solution evenly on the surface of the cigar leaves, and then put them into a burlap bag. Put the burlap bag into a constant temperature and humidity incubator for fermentation, the fermentation conditions are: the fermentation humidity is 75%, the temperature is 35°C, and the fermentation period is 30 days. After the fermentation, the water balance was carried out until the moisture content of the tobacco leaves was 20±1%, and then the sensory evaluation and aroma component testing of the cigar samples were carried out. The results are shown in Table 5 and Table 6.

[0045] In addition, the cocoa medium solution was replaced with pure water, and the blank control group experiment was carried out according to the same procedure.

[0046] Table 5 Effect of cocoa medium on sensory quality of Chuxue-14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com