Iron concentrate beneficiation screening device and screening method thereof

A technology of iron fine powder and mineral processing sieve, which is applied in chemical instruments and methods, sieves, magnetic separation, etc., can solve the problems of poor screening effect and affecting the efficiency of iron fine powder ore dressing and screening, and achieve enhanced uniformity and rapid Sexuality, enhanced convenience, enhanced mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

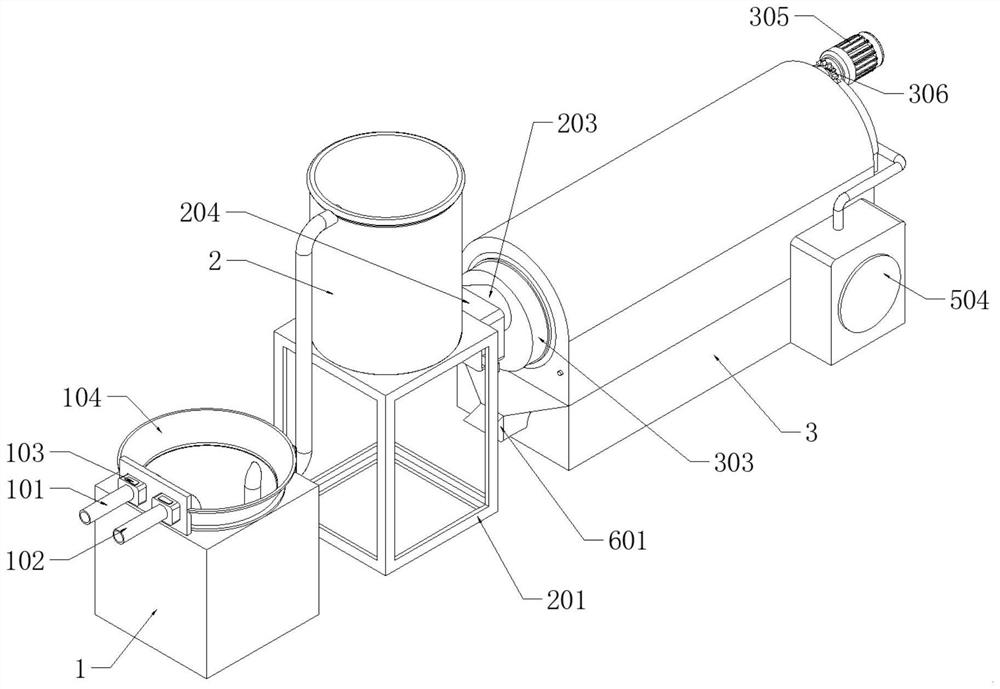

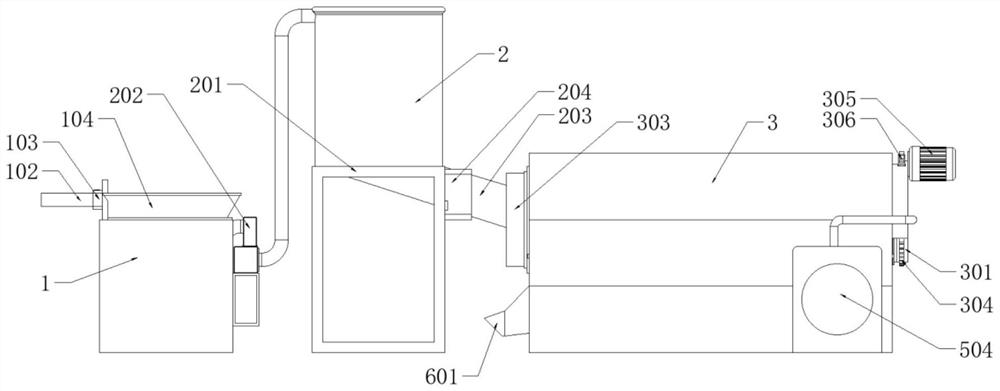

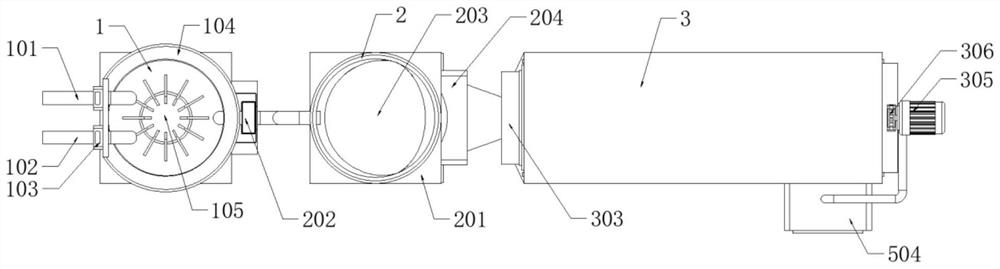

[0051] see Figure 1-10 , a kind of iron fine powder ore dressing and screening device and screening method thereof, comprising a mixing box 1, the top of the mixing box 1 is fixedly installed with an iron fine powder feeding pipe 101 and a water inlet pipe 102 extending to the inside thereof, and the iron fine powder is fed into the The inside of material pipe 101 and water inlet pipe 102 are all fixedly installed with flow valve 103, and the top of mixing box 1 is surrounded and fixed with enclosure 104 inclined from inside to outside. The inside of the fine iron powder feed pipe 101 and the water inlet pipe 102 can control the amount of the iron concentrate powder to be screened and water injected into the mixing box 1 through the iron fine powder feed pipe 101 and the water inlet pipe 102, so that More precise control is used to screen and mix iron ore concentrate powder with water, and fix the enclosure 104 inclined from the inside to the outside on the top of the mixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com