Production method of anti-static organic glass plate substrate

A technology for a plexiglass plate and a production method, which is applied to other household appliances, flat products, household appliances, etc., can solve the problems of high acquisition cost, poor anti-static effect, and easy peeling of the anti-static plexiglass plate coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1 (best embodiment). The production method of antistatic plexiglass board substrate, comprises the following steps,

[0019] Polymerization kettle step, in every ton of MMA raw material (liquid state), add the initiator of 12g low-temperature type, in polymerization kettle, be heated to 95 ℃, keep warm, heat preservation time is determined according to the purity of MMA raw material, when the purity of MMA raw material is greater than 99.9%, The MMA raw material is a commercially available new material, the holding time is 42min, and when the purity of the MMA raw material is 95-97%, the MMA raw material is a commercially available reclaimed material, and the holding time is 70min. After the heat preservation, it is naturally cooled to normal temperature to obtain product A ;

[0020] Mixing step, add 12% initiator and 10Kg plasticizer in every ton of A product, mix evenly, get B product;

[0021] The vacuum filtration step is used to eliminate the air bubb...

Embodiment 2

[0025] Example 2. Different from Example 1, in the polymerization kettle step, 10 g of the initiator is heated to 110° C. in the polymerization kettle. When the purity of the MMA raw material is greater than 99.9%, the holding time is 40 minutes, and the purity of the MMA raw material is 95- When 97%, the holding time is 60 minutes.

[0026] In the mixing step, the initiator is 10g, and the plasticizer is 9Kg.

[0027] In the vacuum filtration step, the relative vacuum is a negative pressure of 0.09 MPa, the vacuum time is 30 min, and the filter material is a 150-mesh filter cloth, which is filtered five times.

[0028] In the universal fixation step, the product D is heated to 95°C.

Embodiment 3

[0029] Example 3. Different from Example 1, in the step of the polymerization kettle, the initiator 15g is heated to 80°C in the polymerization kettle, and when the purity of the MMA raw material is greater than 99.9%, the holding time is 45min, and the purity of the MMA raw material is 95- When 97%, the holding time is 80 minutes.

[0030] In the mixing step, the initiator is 13g, and the plasticizer is 11Kg.

[0031] In the vacuum filtration step, the relative vacuum degree is a negative pressure of 0.07MPa, the vacuum time is 45min, and the filter material is a 300-mesh filter cloth, and is filtered three times.

[0032] In the universal fixation step, the product D is heated to 100°C.

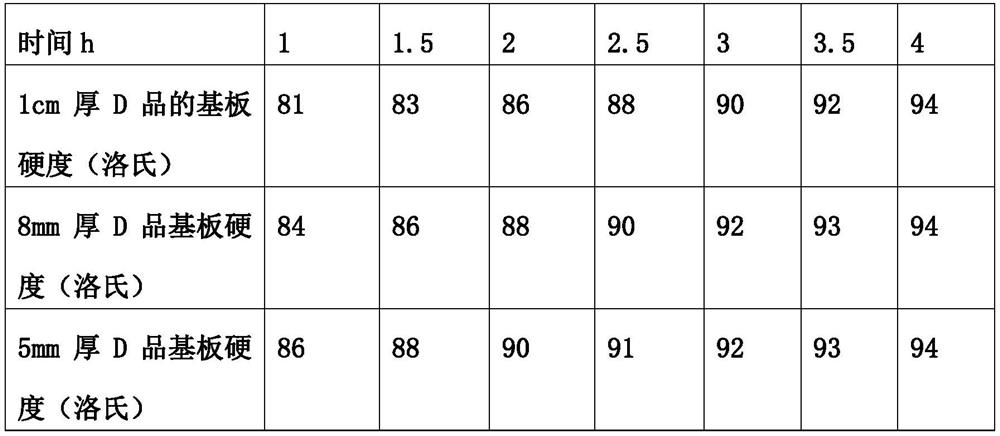

[0033] Embodiment 1 is an improvement made on the production process of domestic substrates. The obtained substrates can be firmly combined with antistatic coatings, and antistatic plexiglass panels can be well produced with low cost. The main points of improvement are: first, in the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com