Wiredrawing cheese sauce and preparation method thereof

A technology of cheese sauce and cream, which is applied in the field of drawn cheese sauce and its preparation, can solve the problems of limited application scenarios of drawn cheese, and achieve the effect of fluidity, strong drawability, and rich milk flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

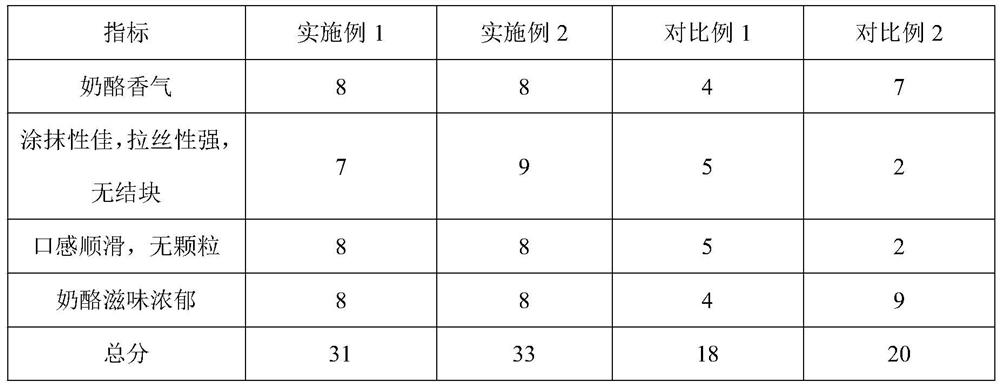

Examples

preparation example Construction

[0028] The present invention also provides a kind of preparation method of shredded cheese sauce, comprises the following steps:

[0029] (1) Pre-mix natural cheese, cream, white sugar, whole milk powder, whey protein powder, emulsifying salt, lactic acid, stabilizer and water for 30 seconds, heat up to 45-50°C, and stir at 1500-2000rpm 3~5min, then continue to heat up to 80~90℃, stirring for 3min;

[0030] (2) Homogenize the material obtained in step (1) with a homogenization pressure of 40 to 80 bar, and keep it warm at 85 to 90°C for 10 to 20 minutes;

[0031] (3) Cool to 10°C to obtain the desired finished product.

Embodiment 1

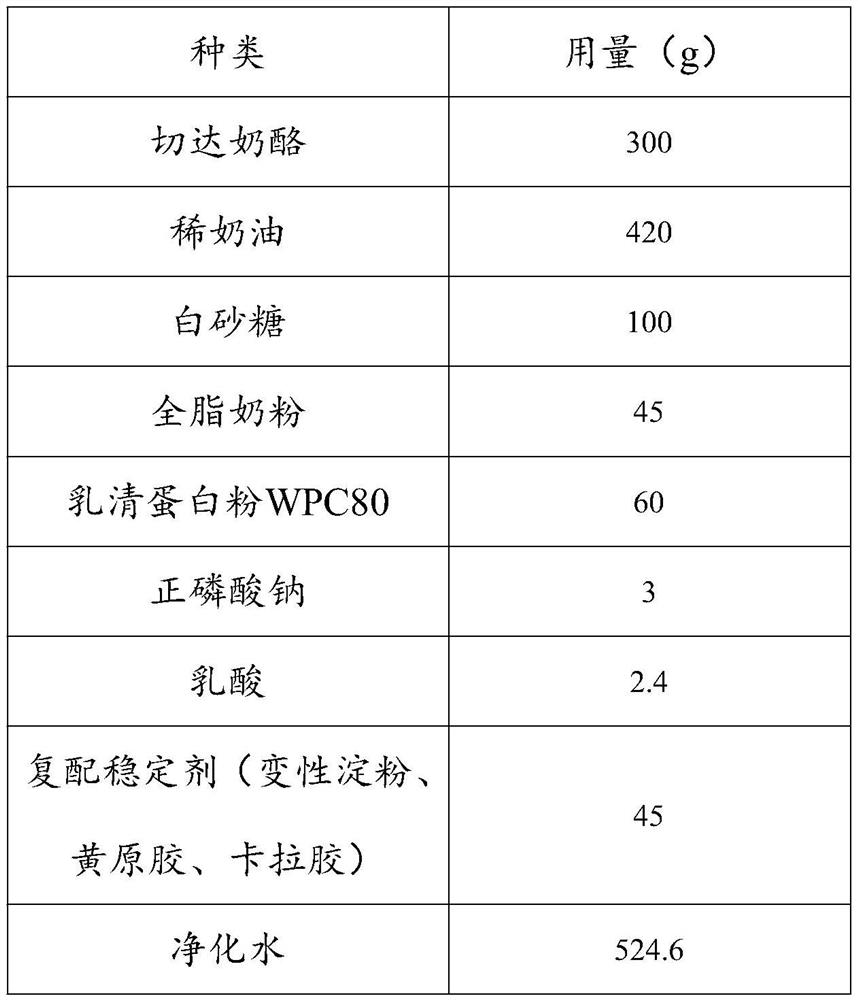

[0034] Raw material formula:

[0035]

[0036] Preparation:

[0037] (1) Premix natural cheese, cream, white sugar, whole milk powder, whey protein powder WPC80, sodium orthophosphate, lactic acid, modified starch, xanthan gum, carrageenan and water for 30 seconds, heat up to 45°C, and Stir at 1500rpm for 3min, then continue to heat up to 80°C, and stir for 3min;

[0038] (2) Homogenize the above materials with a homogenization pressure of 40 bar, and keep warm at 85°C for 10 minutes;

[0039] (3) Cool to 10°C to obtain the desired finished product.

Embodiment 2

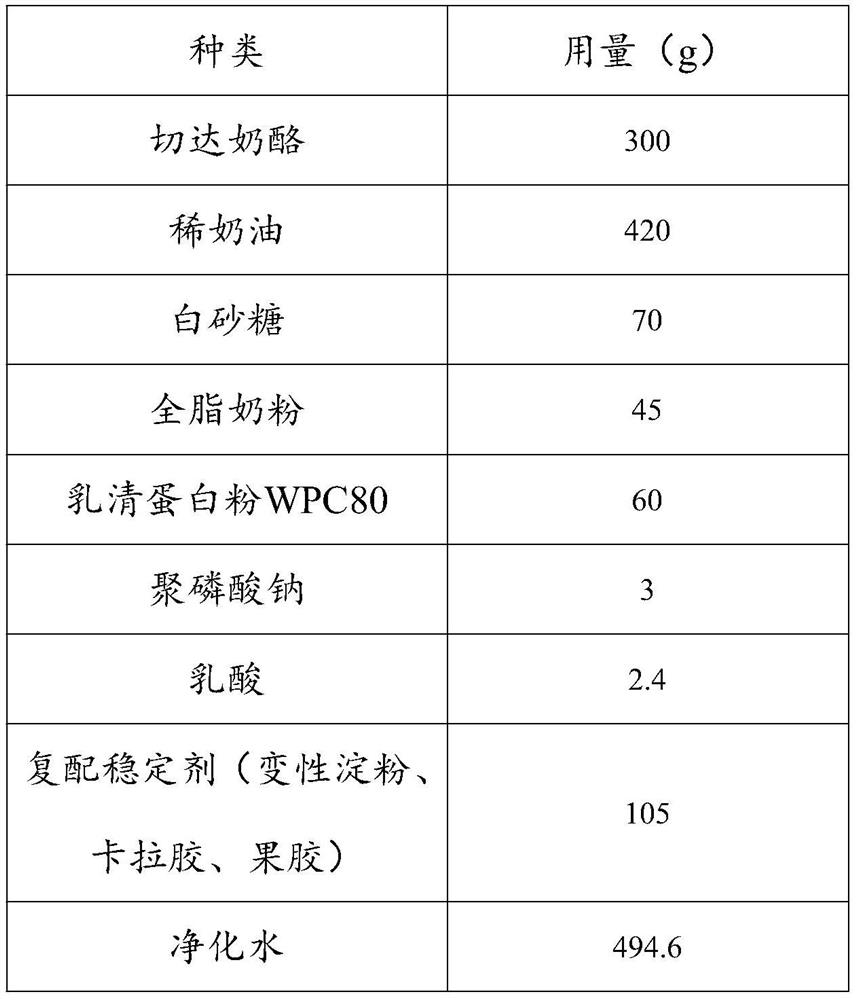

[0041] Raw material formula:

[0042]

[0043] Preparation:

[0044] (1) Premix natural cheese, cream, white sugar, whole milk powder, whey protein powder WPC80, sodium polyphosphate, lactic acid, modified starch, carrageenan, pectin and water for 30 seconds, heat up to 50°C, and Stir at 2000rpm for 5min, then continue to heat up to 90°C, and stir for 3min;

[0045] (2) Homogenize the above materials with a homogenization pressure of 80 bar, and keep warm at 90°C for 20 minutes;

[0046] (3) Cool to 10°C to obtain the desired finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com