Grinding, transporting and sealing device for carbon nanotubes

A sealing device and carbon nanotube technology, which are used in transportation and packaging, mixers with rotary stirring devices, and mixer accessories, etc., can solve problems such as poor sealing, deterioration of heat-sensitive materials, and reduction of carbon nanotube slurry quality. Good quality, good sealing, and the effect of improving effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

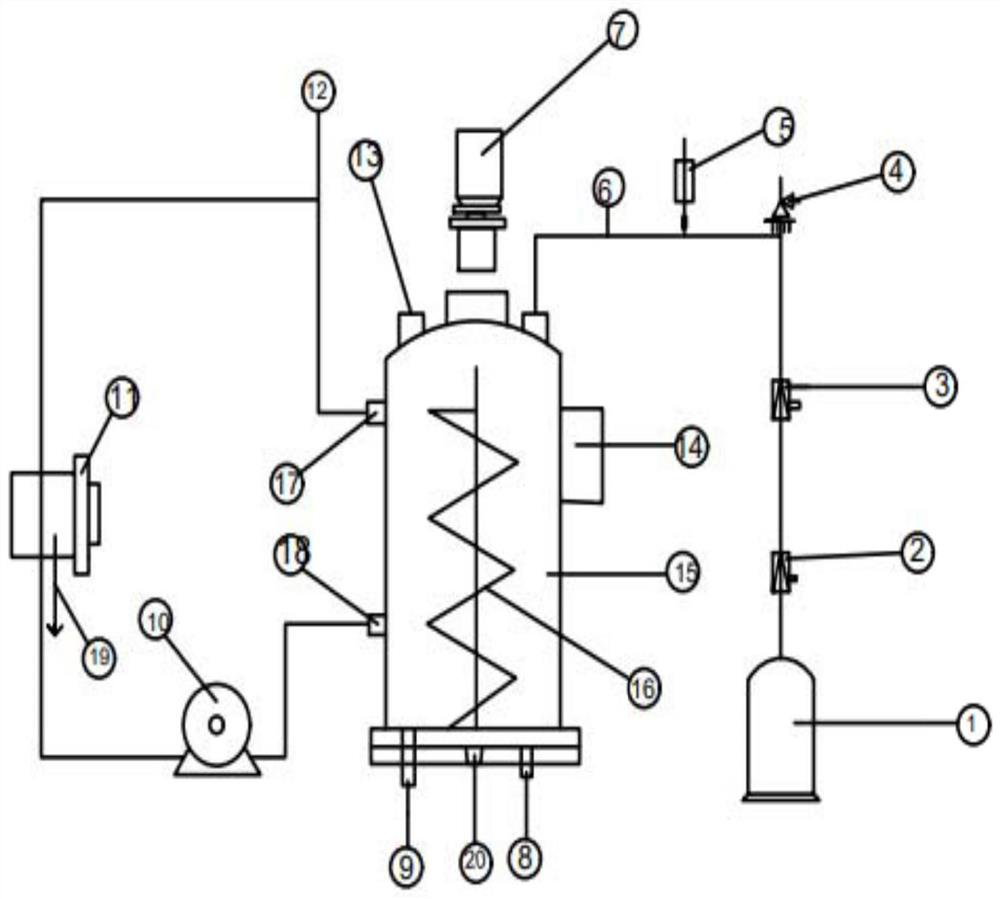

[0026] A grinding transport sealing device for carbon nanotubes, such as figure 1 As shown, it includes a constant pressure mechanism, a first cooling mechanism, a second cooling mechanism and a grinding tank 15, and the grinding tank 15 is a double-layer tank body; the constant pressure mechanism includes an air storage tank 1, and the gas storage tank 1 It communicates with the grinding tank 15; the first cooling mechanism includes a cooling coil 16, and the cooling coil 16 is located inside the grinding tank 15; the second cooling mechanism includes a cooling tank 11, and the cooling tank 11 is connected with a double The interlayer of the tank body is connected; the grinding tank 15 is provided with a grinding device for grinding the carbon nanotube slurry.

[0027] Further, the grinding device is a stirring screw, and the stirring screw is driven by a motor.

[0028] Further, a pressure reducing valve 2 , an air pressure regulating valve 3 , a safety valve 4 , a pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com