Integrated industrial intelligent visual system

An intelligent vision and industrial technology, applied in the field of visual inspection, can solve the problems of difficult operation by non-professionals, inefficient inspection rate, cumbersome installation, etc., and achieve the effect of strong configurability, high inspection efficiency, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

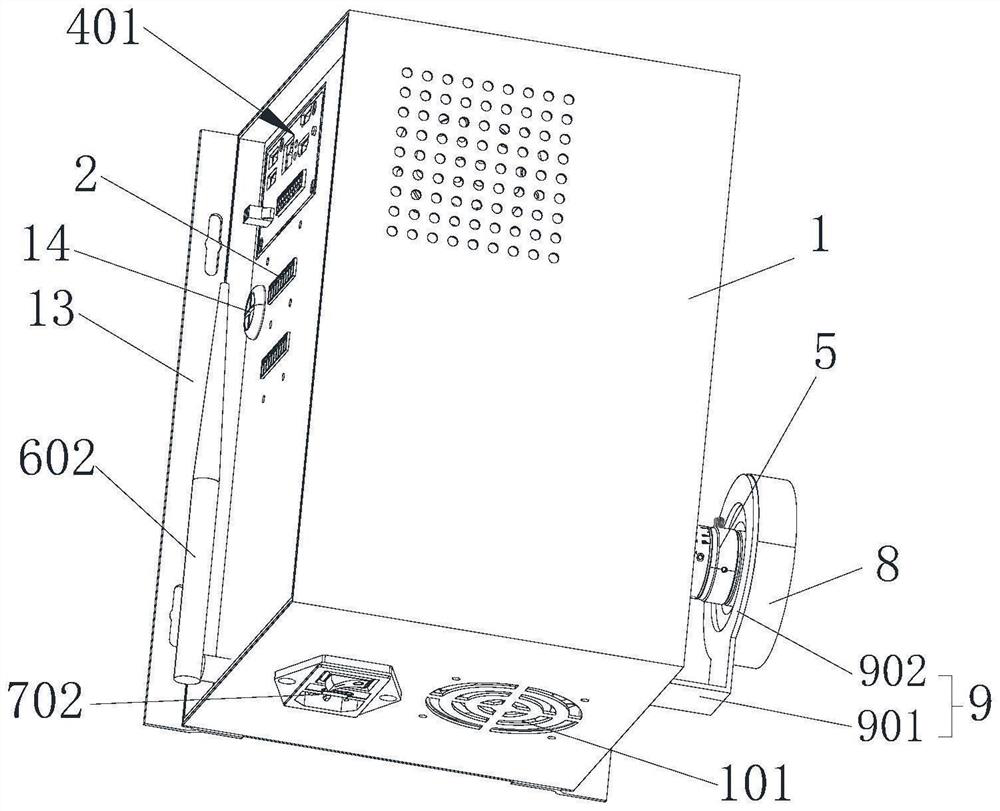

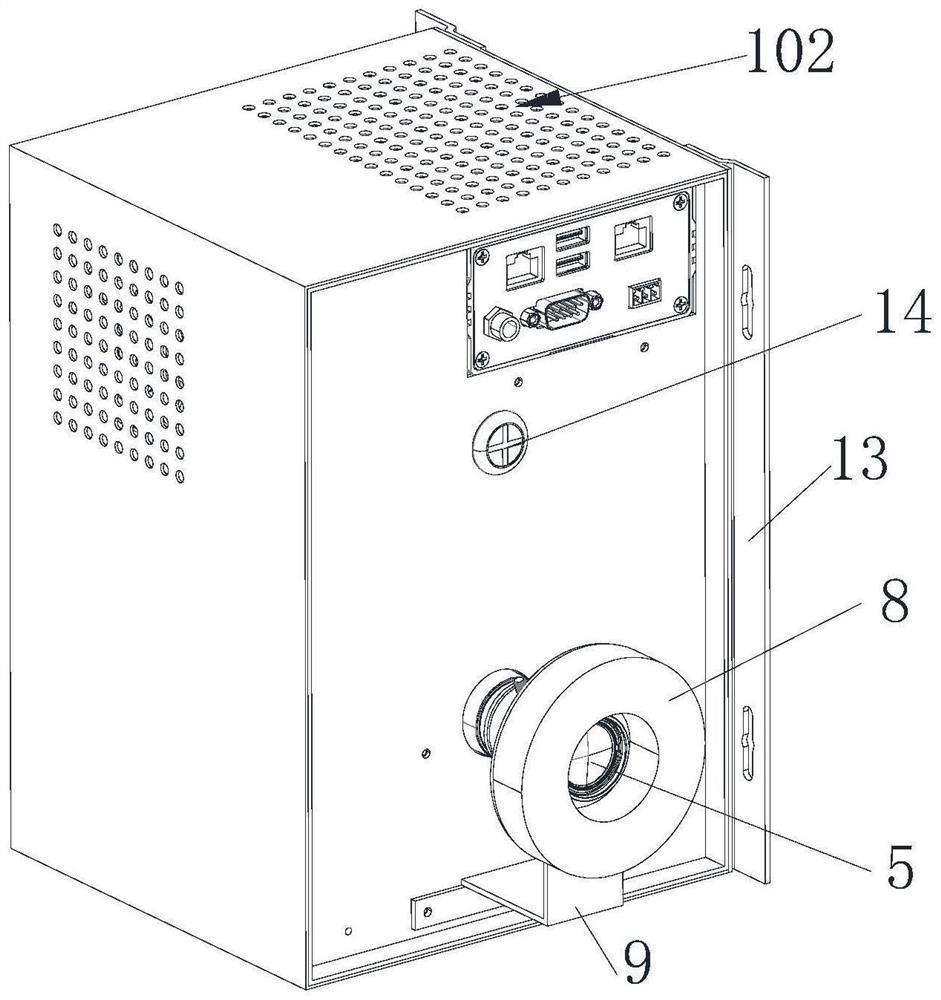

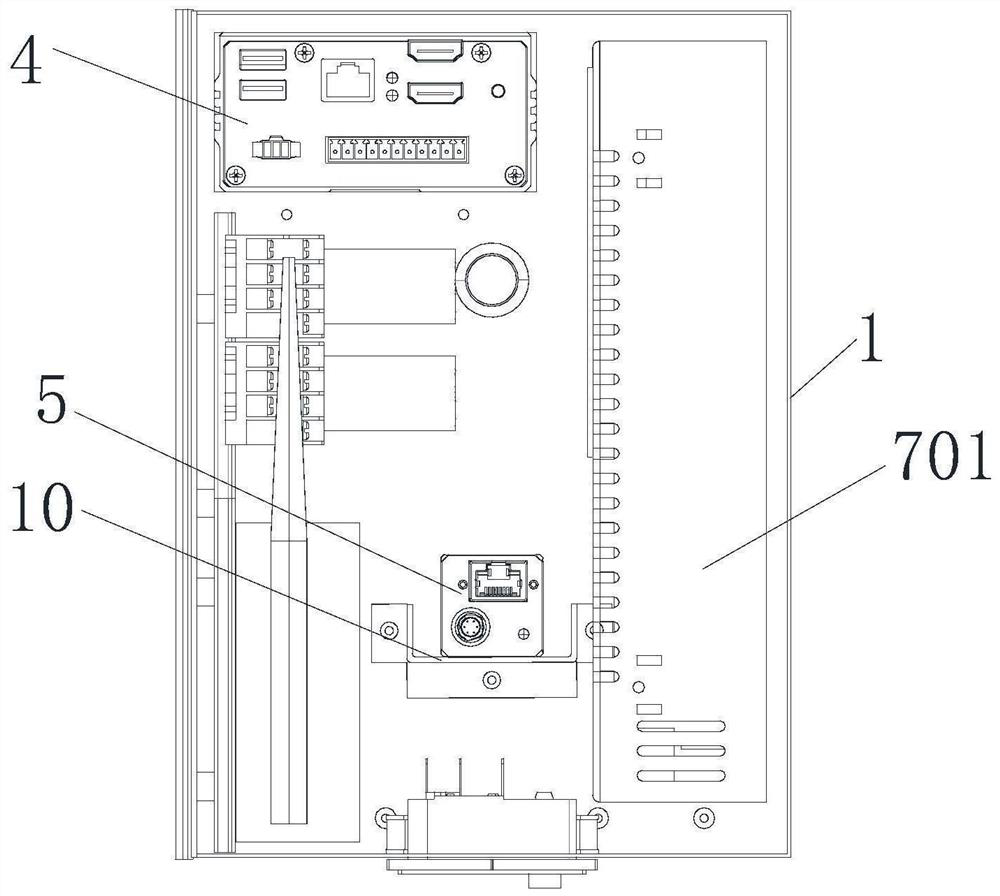

[0053] Please refer to Figure 1 to Figure 7 , the present invention is an integrated industrial intelligent vision system, which includes: a housing 1, a terminal block 2, a relay 3, a controller 4, an industrial camera 5, a wireless communication device 6 and a power supply device 7;

[0054] The connecting terminal 2 is embedded in one side of the casing 1; the relay 3, the controller 4, the wireless communication device 6 and the power supply device 7 are installed in the casing 1; the industrial camera 5 is installed on the side of the casing 1 and the shooting lens of the industrial camera 5 faces the measured object;

[0055] One end of the connection terminal 2 is used for external connection to other on-site electrical components, and the other end of the connection terminal 2 is connected to the controller 4 through the relay 3;

[0056] The signal end of the industrial camera 5 is connected to the controller 4 and is used to send the acquired image of the measured ...

Embodiment 2

[0070] The difference between the second embodiment and the first embodiment is that, on the basis of the first embodiment, a detection method of the controller is added in this embodiment. In this embodiment, the controller uses traditional morphological algorithms and deep learning algorithms for visual detection, and detects object size, flaws, scratches, etc. according to requirements. The detection method of the controller is:

[0071] Step 1: Obtain the image of the measured object captured by the industrial camera;

[0072] Step 2: Preprocessing the image: image filtering, image enhancement and contour enhancement;

[0073] Step 3: Image matching and positioning, image correction processing;

[0074] Step 4: After image comparison, extract defects and judge;

[0075] Step 5: Result output.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com