Preservative film guiding and covering device for food packaging

A covering device and food packaging technology, which is applied in the field of food packaging cling film guiding and covering device, can solve the problems of inability to remove dust, scratches on the surface, and the effect of cling film cannot be fully exerted, so as to avoid temperature influence and not easily deform. , the effect of preventing coverage from being blocked

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

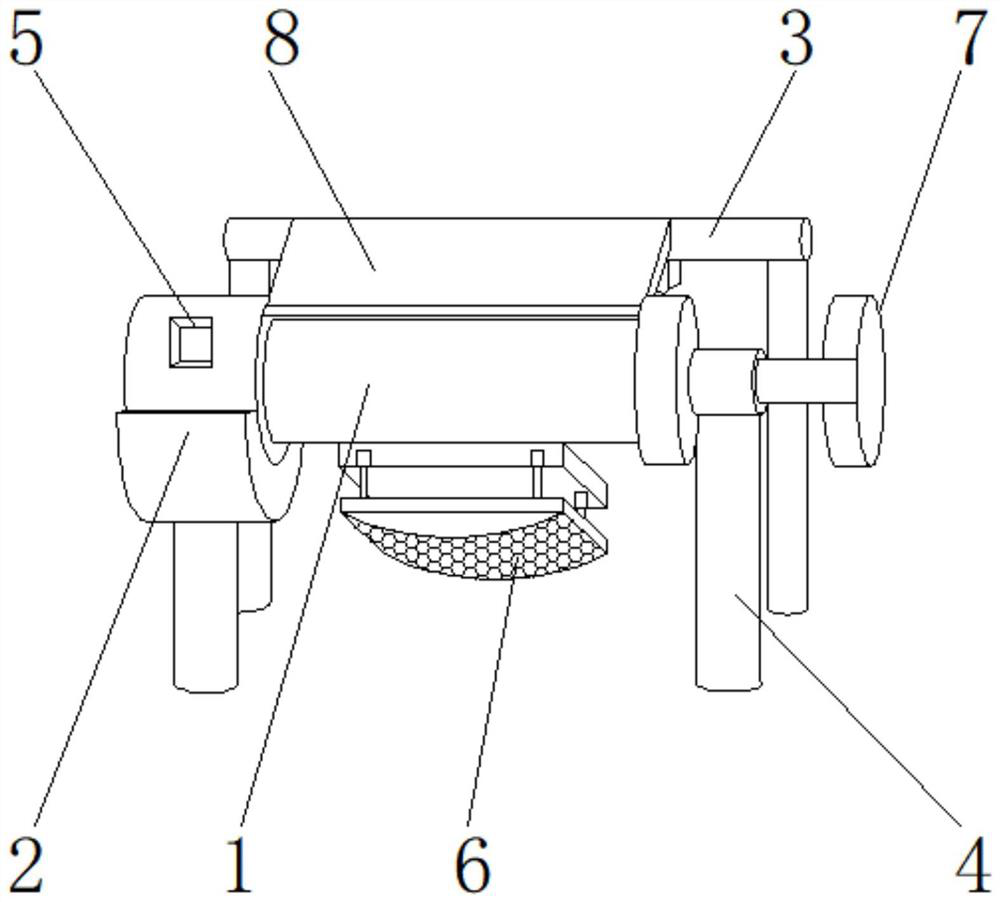

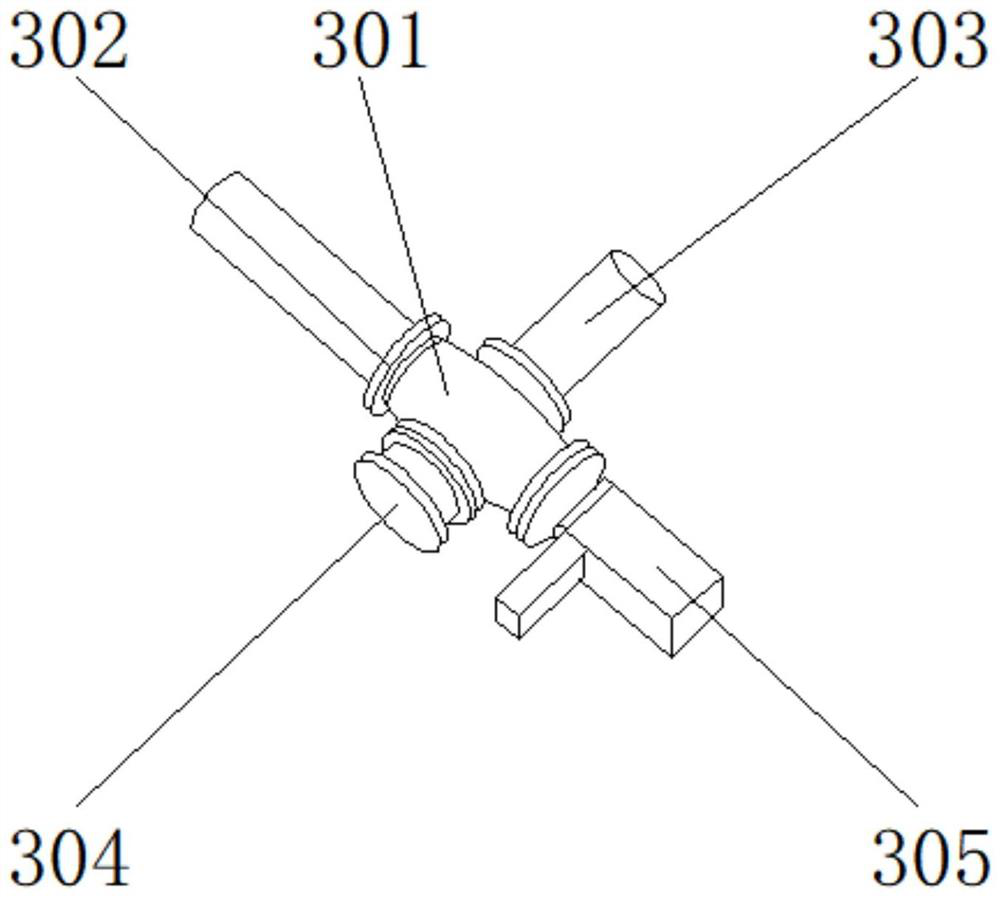

[0027] Such as Figure 1-5 As shown, the present invention provides a fresh-keeping film guiding and covering device for food packaging, comprising a main body 1, a cutting board 8 is arranged on the upper end of the main body 1, a temperature control mechanism 3 is arranged on the rear end of the cutting board 8, and the main body 1 The lower end is provided with an anti-wear mechanism 6, one side of the main body 1 is provided with a cleaning mechanism 5, the lower end of the cleaning mechanism 5 is provided with a storage tube 2, the lower end of the storage tube 2 is provided with a support column 4, and the other side of the main body 1 is provided with a There is a rotating shaft 7; the temperature control mechanism 3 includes a heat pipe 301, a valve 302, a condensation pipe 303, a heater 304, and a constant temperature block 305. The valve 302 is located on one side of the heat pipe 301, and the condensation pipe 303 is located at the rear end of the heat pipe 301; The...

Embodiment 2

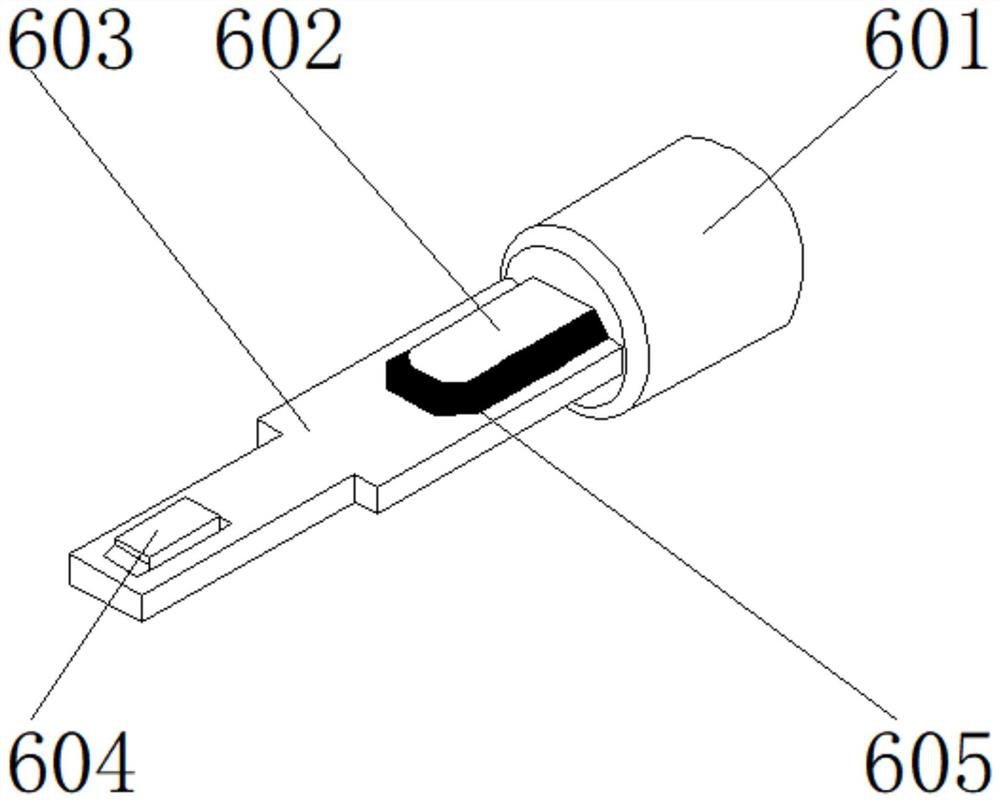

[0030] Such as Figure 1-5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the anti-wear mechanism 6 includes a soft rubber ring 601, an induction plate 602, a limit plate 603, an insulating plate 604, and a cushion 605, The limiting plate 603 is located on one side of the soft rubber ring 601, the soft pad 605 is located on the upper end of the limiting plate 603, the insulating plate 604 is located on one side of the soft pad 605, the induction plate 602 is located on the upper end of the soft pad 605, and the soft rubber ring Superglue is arranged between 601 and the limiting plate 603, one side of the limiting plate 603 is fixedly connected with one side of the soft rubber ring 601 through superglue, and a screw is arranged between the limiting plate 603 and the cushion 605 to limit The upper end of the position plate 603 is fixedly connected with the lower end of the soft pad 605 by screws, a Phillips screw is arran...

Embodiment 3

[0033] Such as Figure 1-5As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the cleaning mechanism 5 includes a storage box 501, a screen 502, a feed pipe 503, a pressure stabilizing roller 504, and an air blast pipe 505, The screen 502 is located on the outer surface of the upper end of the storage box 501, the pressure-stabilizing roller 504 is located on one side of the screen 502, the feed pipe 503 is located on the upper end of the pressure-stabilizing roller 504, and the blast pipe 505 is located on one side of the pressure-stabilizing roller 504. A fixing buckle is arranged between the net 502 and the storage box 501, the lower end of the screen 502 is fixedly connected with the upper end of the storage box 501 through the fixing buckle, a groove is arranged between the storage box 501 and the pressure stabilizing roller 504, and the pressure stabilizing roller 504 The lower end is fixedly connected with the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com