Semi-automatic boxing clamp for square battery module

A square battery, semi-automatic technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of many automatic handling jaw accessories, high cost of detection sensors, and low manual handling efficiency, so as to improve handling efficiency and reduce handling Cost, avoid the effect of poor adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

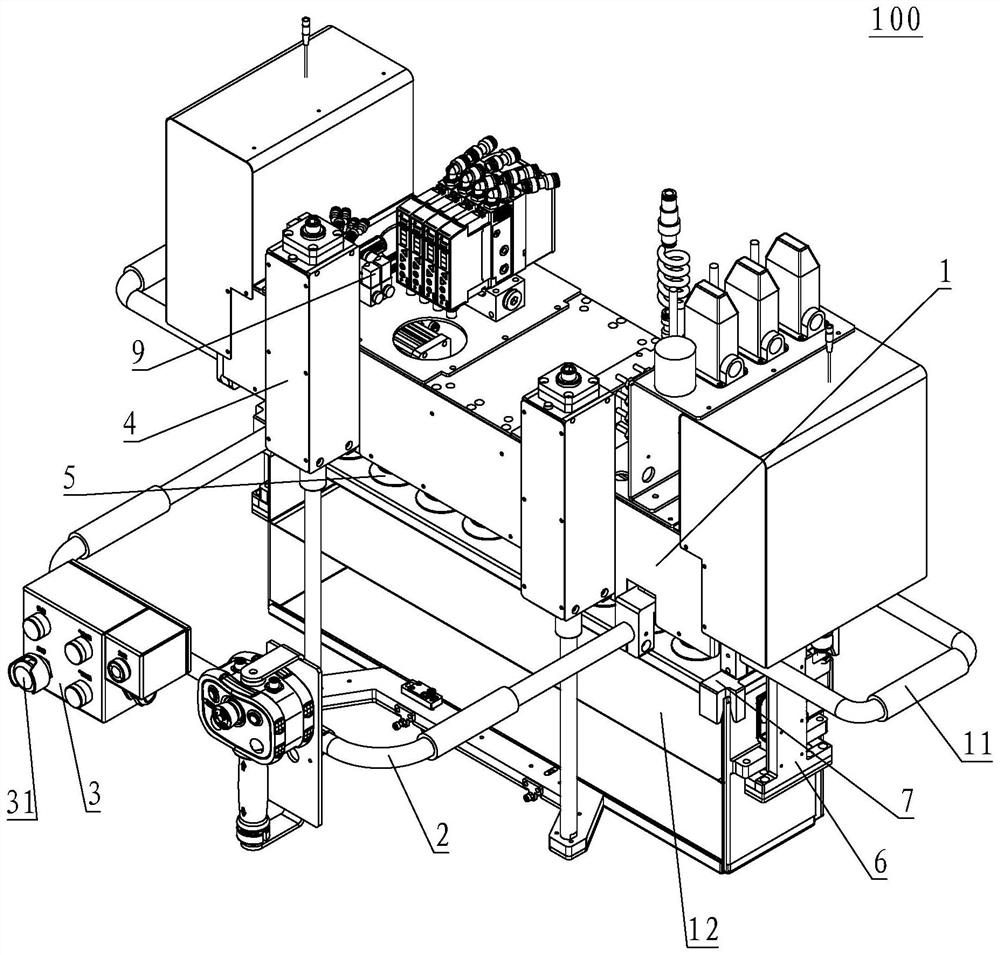

[0060] The embodiment of the present invention provides a semi-automatic box-in jig 100 for square battery modules, which solves the technical problems of low manual handling efficiency and possible drop, and high cost of automatic handling in the prior art, and achieves a great improvement in battery capacity. The safety and efficiency of module handling greatly reduces the technical effect of handling costs.

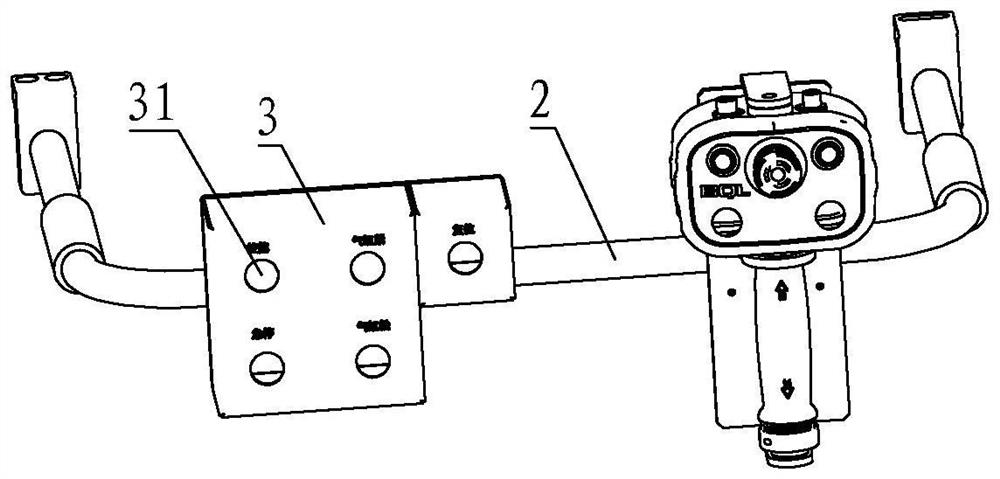

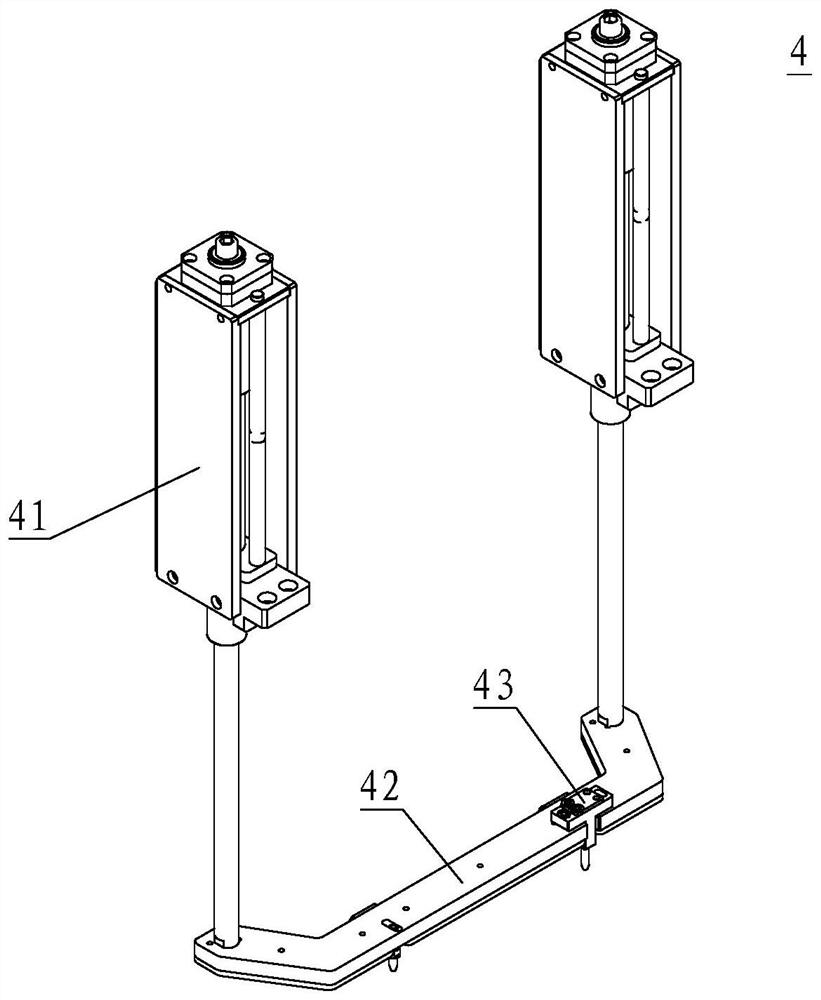

[0061] The technical solution in the embodiment of the present invention is to solve the above problems, the general idea is as follows: set the positioning mechanism 4 and the limit mechanism 7 to position and limit the battery module 12 to ensure that the battery module 12 is clamped at the correct position, and then Set the anti-drop mechanism 6 to cover the bottom of the battery module 12 to prevent the battery module 12 from falling during the clamping process, and set the proximity sensor 8 to judge whether the semi-automatic box-entry fixture 100 is placed in pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com