Automatic electrochemical reaction chamber and control method thereof

An electrochemical reaction and reaction chamber technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of water quality decline, inconsistent water quality, large power consumption, etc., to achieve The brushing resistance is large, the effective utilization rate and the water quality of the produced water are improved, and the effect of increasing the brushing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

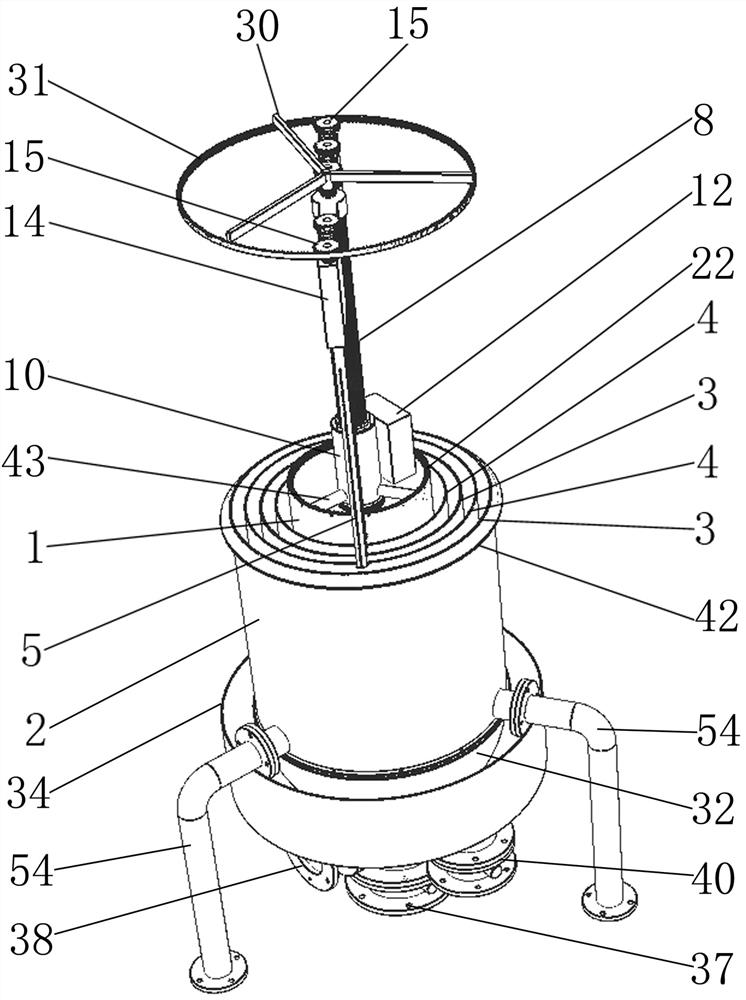

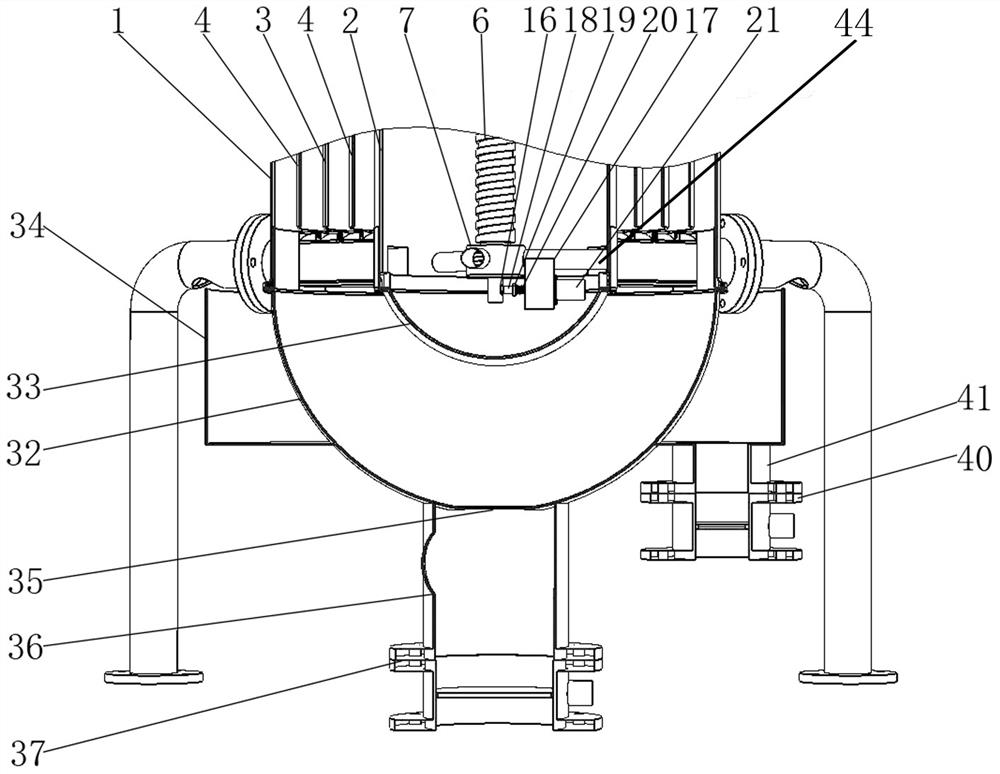

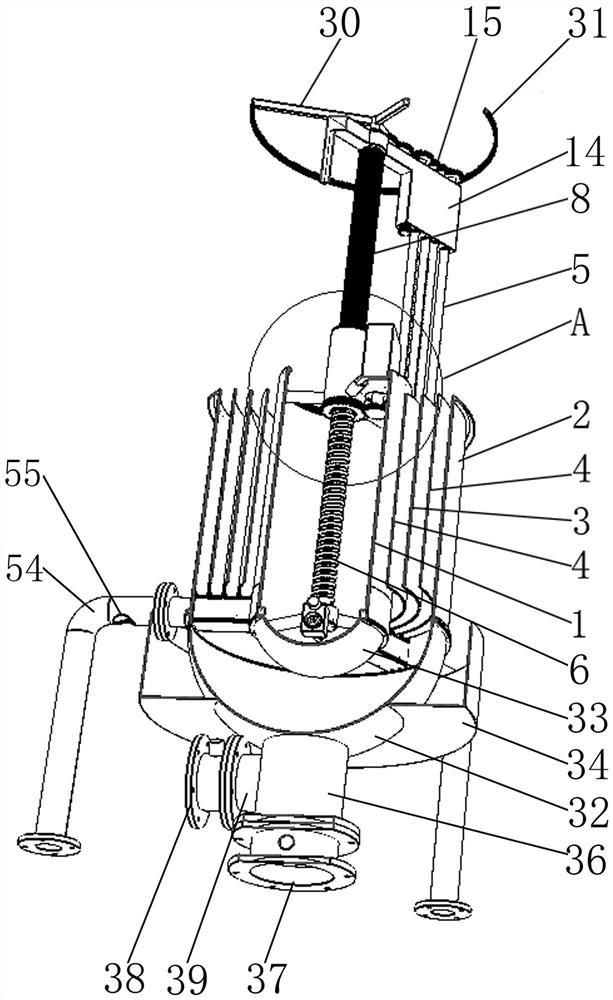

[0061] An automatic electrochemical reaction chamber, including a main body and a control part, the main body includes a reaction chamber body, a water inlet and outlet mechanism, a descaling mechanism and a descaling driving mechanism;

[0062] as attached figure 1 - attached Figure 6 As shown, the reaction chamber body includes a cylindrical inner cathode cylinder 1 located in the middle, an outer cathode cylinder 2 coaxial with the inner cathode cylinder 1 is arranged on the outside of the inner cathode cylinder 1, and a Several electrode cylinders are coaxial with the two and distributed at intervals. The electrode cylinders are composed of cathode cylinders 3 and anode cylinders 4 in a staggered distribution, and the anode cylinders 4 and cathode cylinders 3, the inner cathode cylinder 1 and the outer cathode cylinder 2 form Staggered distribution; the bottom of the electrode cylinder, inner cathode cylinder 1, and outer cathode cylinder 2 is provided with a supporting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com