Large-diameter drainage pipeline construction assembly for water conservancy project and construction method

A technology for drainage pipelines and water conservancy projects, which is applied in the direction of sewer pipeline systems, waterway systems, drainage structures, etc., can solve the problems of easy penetration of soil, pollution diffusion, damage to the inner cavity wall of drainage wells, etc., and achieves the effect of improving safety and facilitating cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

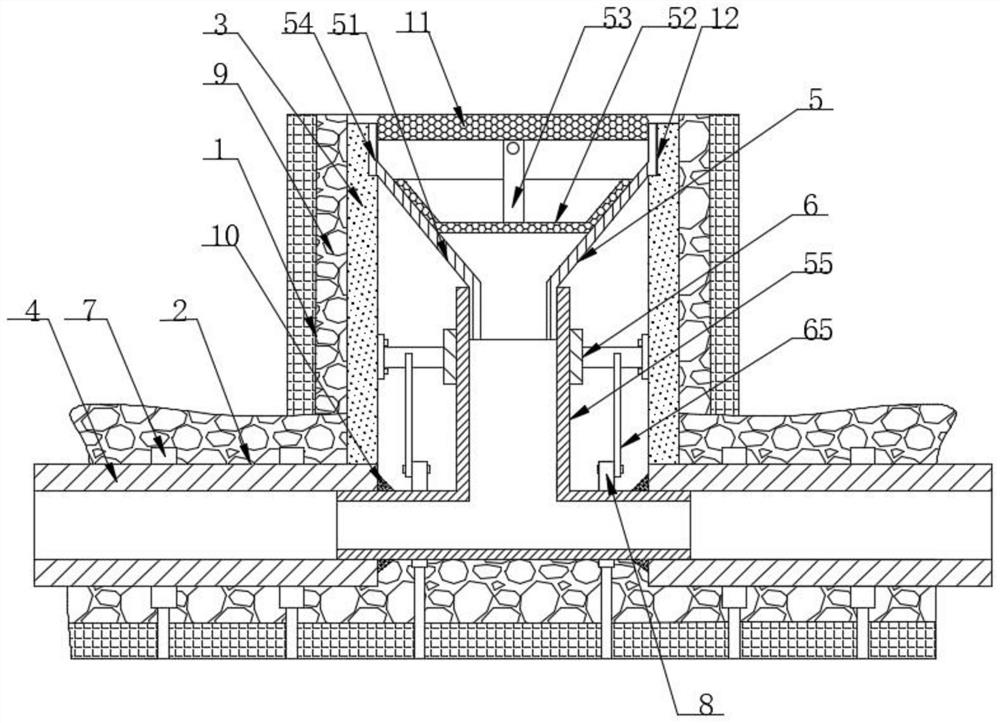

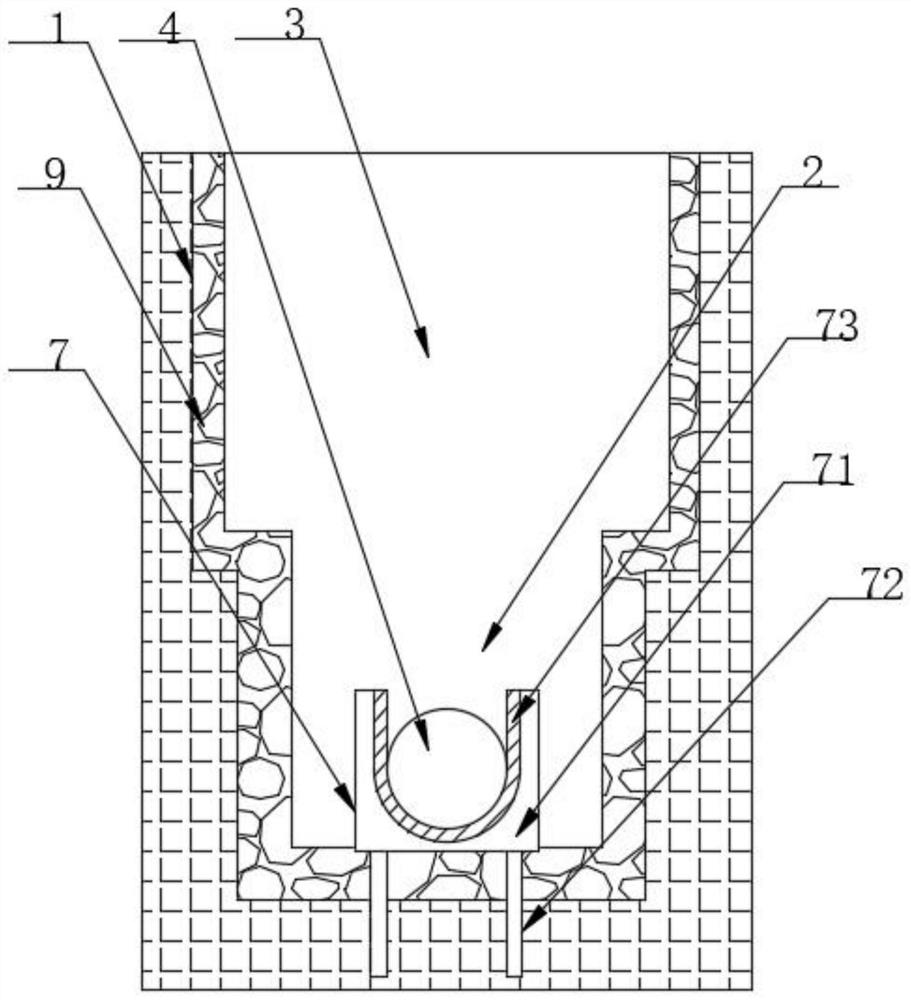

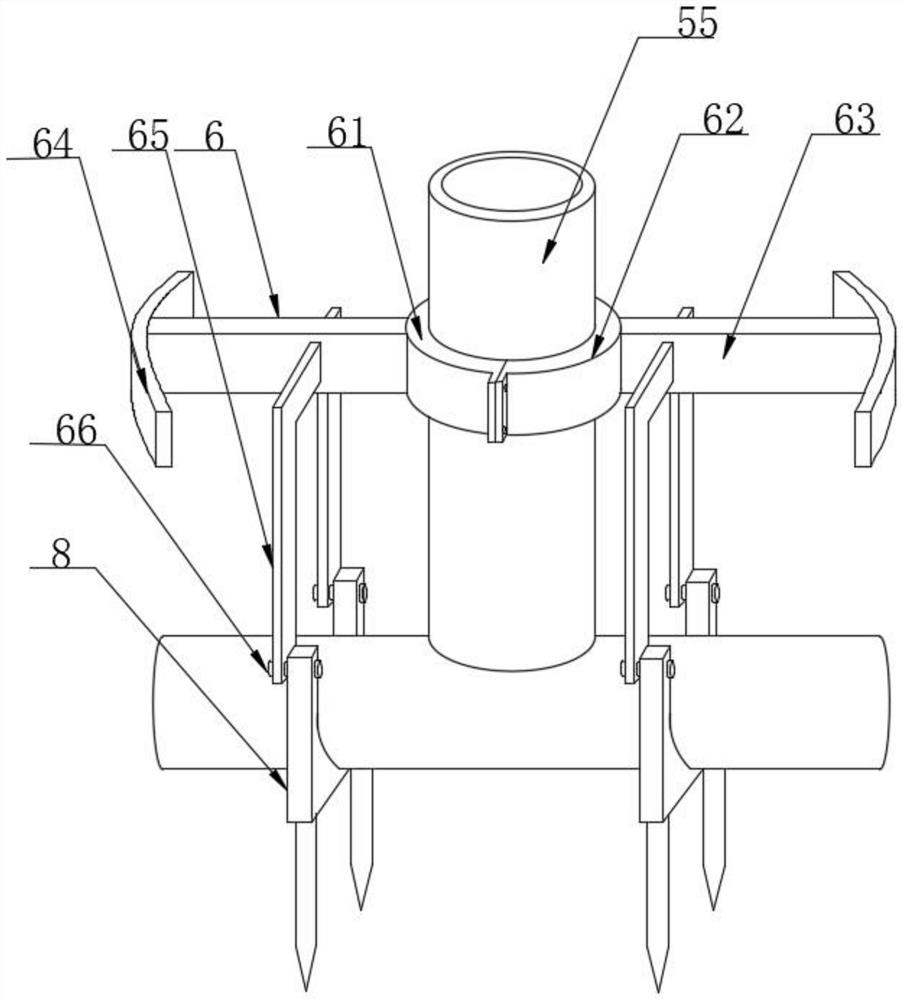

[0034] The following is attached Figure 1-4 The present invention is described in further detail.

[0035] The embodiment of the invention discloses a construction component and a construction method of a large-diameter drainage pipe for water conservancy projects. refer to Figure 1-4 , a large-diameter drainage pipe construction assembly for water conservancy projects, comprising a drainage well 1, a groove 2, a cement pipe 3 and a drainage pipe 4, both sides of the drainage well 1 are fixed with grooves 2, and the inner cavity of the drainage well 1 Cement pipe 3 is installed, and drainpipe 4 is installed in the cavity of groove 2, and drainpipe 4 is positioned at the bottom end of both sides of cement pipe 3, and the cavity of cement pipe 3 is equipped with conical drainage mechanism 5, drainage well 1 and The inner wall of the trench 2 is fixed with a concrete layer 9;

[0036] The conical drainage mechanism 5 comprises a conical water collecting bucket 51, and the co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap