Transformer fault sound source positioning method and system based on microphone array

A microphone array and transformer failure technology, applied in the field of transformers, can solve the problems of high labor cost, reliability, repeatability, accuracy, rough fault location, etc., and achieve the effect of easy maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

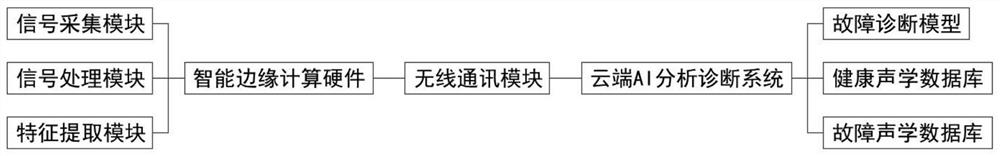

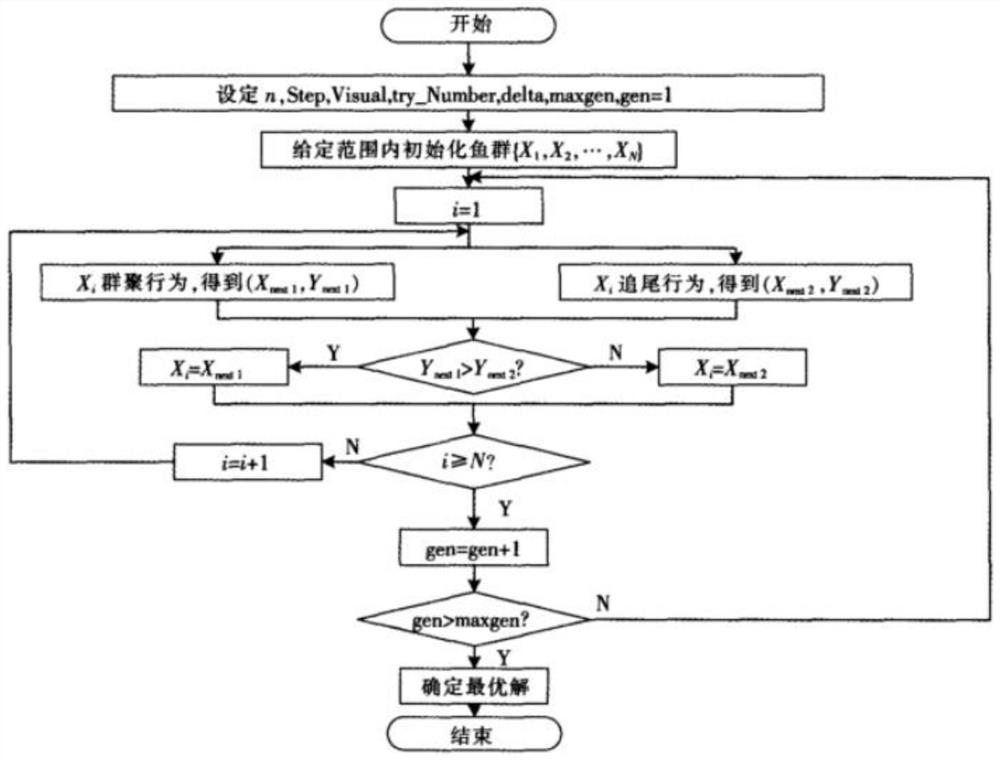

[0040] see figure 1 and figure 2 , the present invention provides a technical solution: a method for locating a sound source of a transformer fault based on a microphone array, comprising the following steps:

[0041] S1. Obtain the acoustic signal x(t) at the measurement surface through the microphone array;

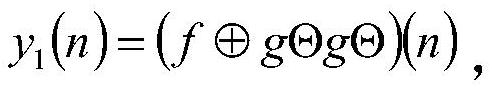

[0042] S2. Use the improved multi-scale morphological filter to perform noise suppression on the acoustic signal x(t), and obtain the filtered denoising signal That is, the transformer equipment in a pure state radiates noise signals. Since there is often more than one kind of interference noise in the sound field where the actual transformer equipment is located, and the interference noise in the acoustic signal x(t) is usually random, therefore, it is necessary to use multi-scale The different structural elements of construct the morphological filter to avoid serious filter output statistical shift:

[0043] The noise suppression step includes: S21, performing me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com