Quantitative evaluation system and method for reducing risks of production operators

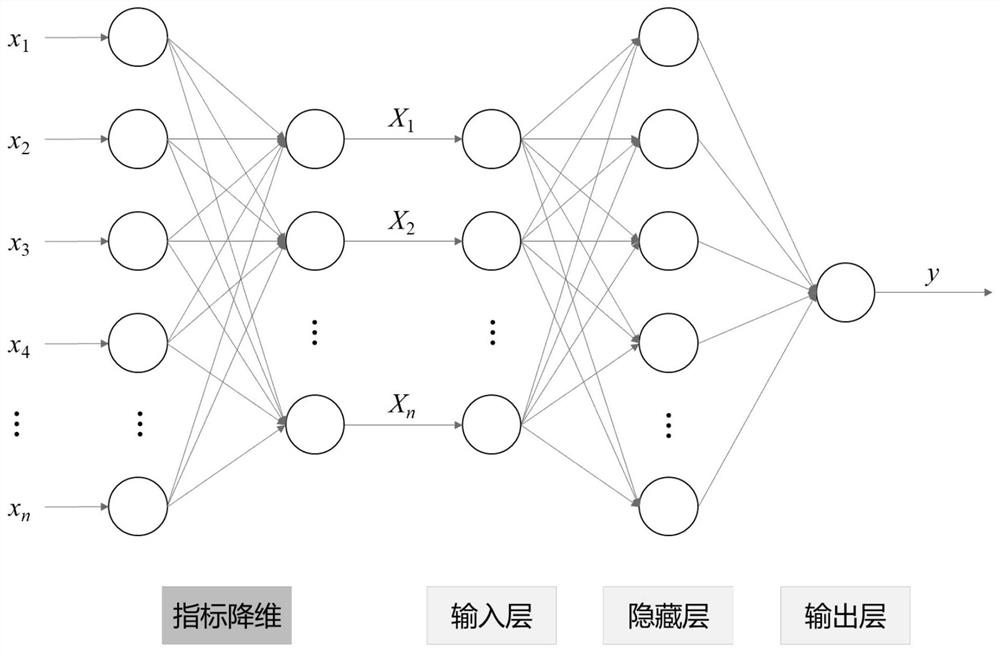

A quantitative evaluation and operator technology, applied in neural learning methods, information technology support systems, biological neural network models, etc., can solve the problems of less personal safety risks and no one cares about it, so as to improve the level of personal safety and ensure accuracy , to ensure comprehensive and scientific results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Embodiment 1 A quantitative evaluation method for reducing the risk of production workers

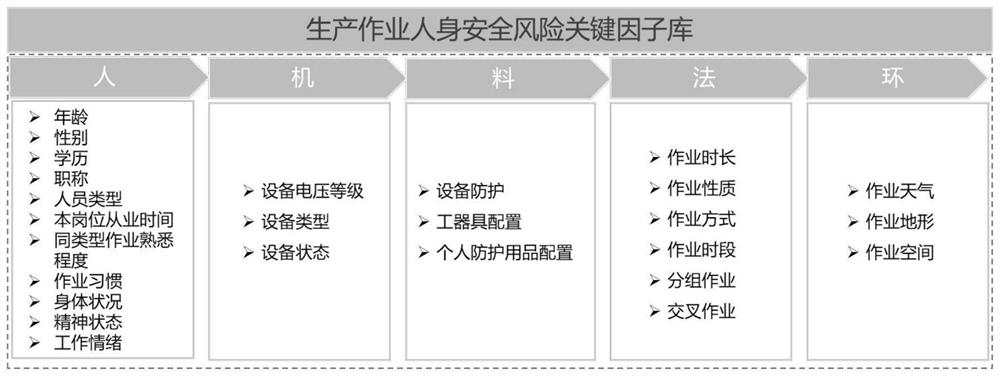

[0074] 1. Construction of key risk factor database

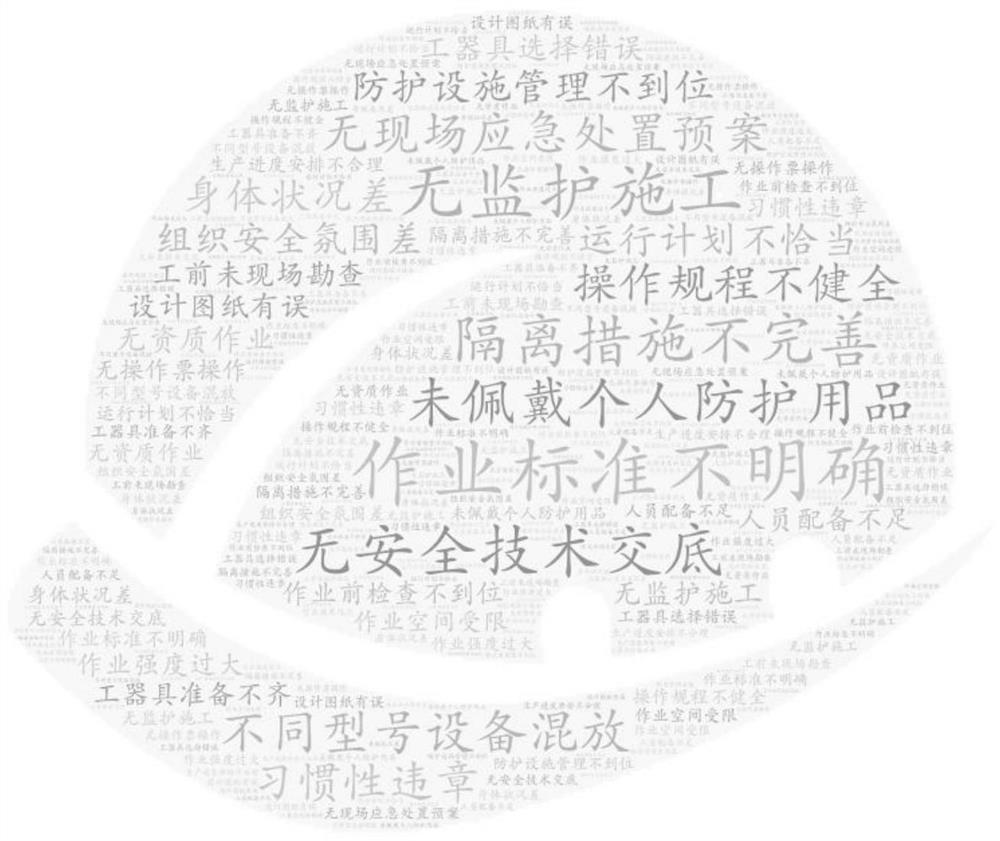

[0075] 1.1 Frequency extraction of personal safety risk words based on TF-IDF

[0076] 1.1.1 Using the TF-IDF algorithm, through the Python software, the "Accident Report" and "National Power Safety Production Situation" of the National Energy Administration from January 2016 to May 2020, and some accident report documents of the State Grid Corporation of China to carry out key words Analyze, sort and sort the Python execution results according to the weight of TF-IDF, filter out the 40 words with the highest weight of TF-IDF in the file, and list the keyword extraction result table, as shown in Table 1;

[0077] Table 1 Keyword extraction result table

[0078]

[0079]

[0080] 1.1.2 Based on the keyword extraction results, combined with the actual work and characteristic elements of the production operation site, 24 k...

Embodiment 2

[0171] Example 2 Analysis of Typical Samples of Production Operations 1

[0172] (1) Analysis of the original sample

[0173] 1. Data collection and model testing

[0174] Different from Example 1, this example takes the production operation plan from March to August 2020 as a screening sample, and finally determines a total of 2,500 original samples covering key information such as companies, temporary plans and non-temporary plans in various cities in Gansu Province , according to the distribution of samples in each unit, after sorting and screening, 2087 effective samples were recovered in this embodiment, and the effective recovery rate was 83.48%. The situation of each unit is as follows Figure 10 shown. After eliminating invalid samples, the model test is carried out according to 2087 valid samples. The 2087 effective samples are tested in the form of "overall + sub-unit", and the vectorized evaluation model is imported into the input file to obtain the operation res...

Embodiment 3

[0177] Example 3 Analysis of typical samples of production operations II

[0178] (1) New sample analysis

[0179] 1. Data collection

[0180] The difference from Example 2 is that in this example, based on the analysis of the production and operation day control plan of the Gansu company, taking October 2020 as the sample period, five prefecture cities of Jinchang, Jiuquan, Lanzhou, Longnan, and Qingyang were randomly and equally selected. Each company has 100 pieces of production operation information, a total of 500 pieces of production operation information, and issued the "State Grid Gansu Provincial Electric Power Company Production Operation Personal Safety Risk Quantitative Evaluation-Data Collection Form" to collect key field information, and found through the recovery and sorting of the data collection form, excluding formats and There are 452 invalid samples whose content is incorrectly filled in, and the remaining valid samples are 452. For the distribution of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com