Method for purifying polyalkylaluminoxane-containing solution using hydroxyl group-containing compound and catalyst composition using same

A technology of polyalkylaluminoxane and alkylaluminoxane is applied in the field of using hydroxyl-containing compound to purify polyalkylaluminoxane-containing solution and using the catalyst composition to prevent interference of trialkylaluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation of a solution containing polyalkylaluminoxane can be included in the present invention without consideration of obtaining a method or route of a solution containing polyalkyl aluminoxane, but specifically, it may refer to obtaining polyalkyl groups. Commercial solution of aluminoxane is prepared. Currently commercially available polyalkyl aluminoxanes were sold in a solution of dissolved in a hydrocarbon solvent, and containing a predetermined amount of trialkyl aluminum, therefore, there is a problem that the catalytic activity of the degradation of the main catalyst is present in the participating polymerization. It is an object of the present invention to be purified to effectively remove the trialkyl aluminum contained in the solution of the polyalkylaluminoxane prepared in step (S1), and therefore, when the olefin polymer is produced, removal is used more efficiently. The solution of polyalkylaluminoxane containing triesyl aluminum.

[0030] A polyalkyl...

Embodiment

[0088] Hereinafter, the present invention will be described in detail with reference to the examples. However, the following examples are intended to illustrate the examples of the present invention and are not intended to limit the scope of the invention.

[0089] Preparation reagent]

[0090] Polyisine aluminoxane is used from Tosho Co., Ltd., dissolved in hexane. The solution-containing-containing aluminoxane-containing solution containing 4.4 mol% of trisobutyl aluminum is included in Tosho Co., Ltd.. Purchased of hydroxyl compounds from Aldrich Co., Ltd. Or TCICO., LTD.

[0091] [Preparation and purify solution containing polybutyl aluminoxane]

[0092] Example 1

[0093] Add 2.00 equivalents of 1,3,5-trihydroxybenzene (1 equivalent trisutyrobutyyl aluminum containing the polyisobutyl aluminoxane) to 500 ml of Shuorek, and dry dry for 3 hours . The solution of 175 g of polyisobutyl aluminoxane and 175 g hexanes were added to another 500 ml of Shulekkota, and were prepared.

...

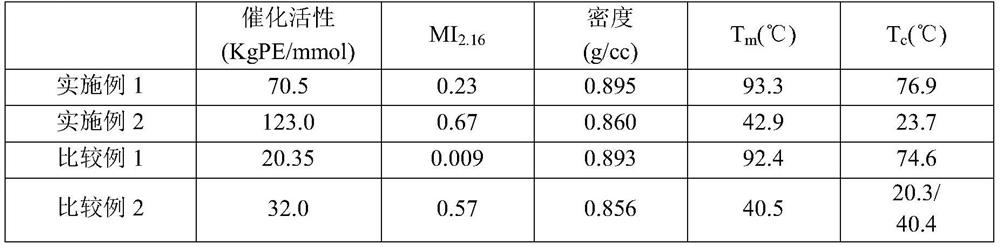

experiment example 1

[0103] (1) Trudobutyl aluminum (mole%)

[0104] By carrying out the above filtration 1 H NMR was dissolved in THF deuterated solvent and the content of the remaining trisobutyl aluminum was measured.

[0105] (2) Filtering time (hours)

[0106] Measuring the time of the filtration input through the filter.

[0107] (3) Recycling rate (%)

[0108] Recycling rate (%) = a solution (G) of polyisobutyl aluminoxane-containing aluminoxane in solution (G) / reactant-containing solution after filtration (G) × 100 × 100

[0109] [Table 2]

[0110] Trudobutyl aluminum (mole%) Filtering time (hours) Recovery rate(%) Example 1 <0.1

0.1 94 Example 2 2.900 0.1 95 Example 3 <0.1

24.0 90 Example 4 <0.1

0.1 95 Example 5 <0.1

0.1 90 Production example 6 1.176 0.1 90 Example 7 0.137 0.1 90 Production example 8 1.470 0.1 90 Example 9 <0.1

0.1 90 Production example 10 <0.1

0.1 90 Example 11 0.176 0.1 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com