Antimicrobial medical gloves

An anti-microbial, mixture technology, applied in gloves, surgical gloves, applications, etc., can solve problems such as inability to replenish, reduce, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

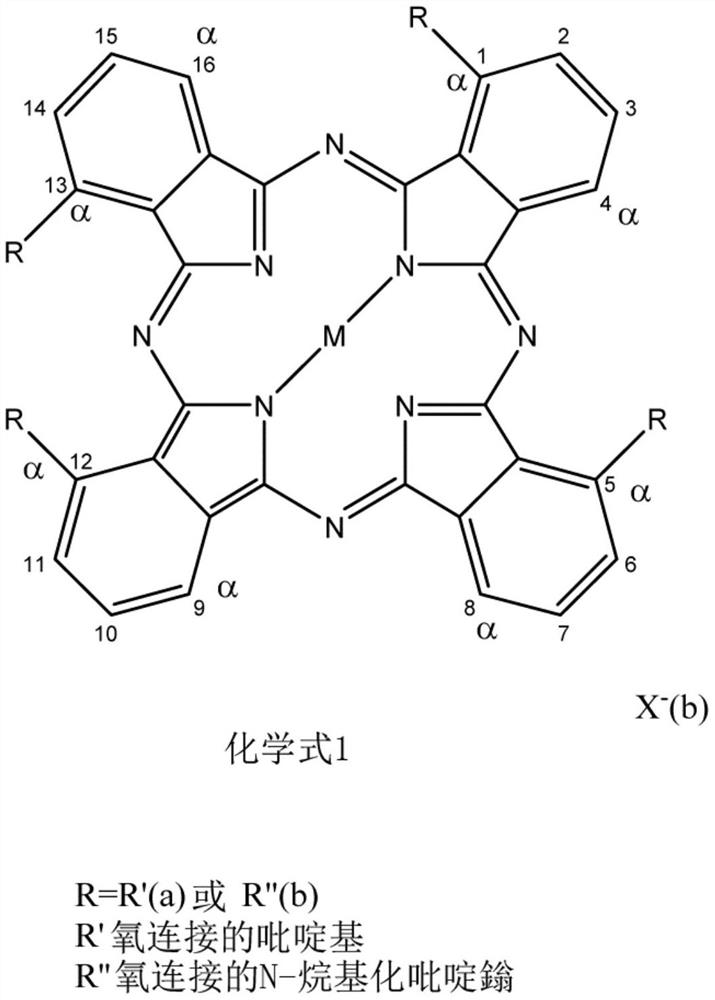

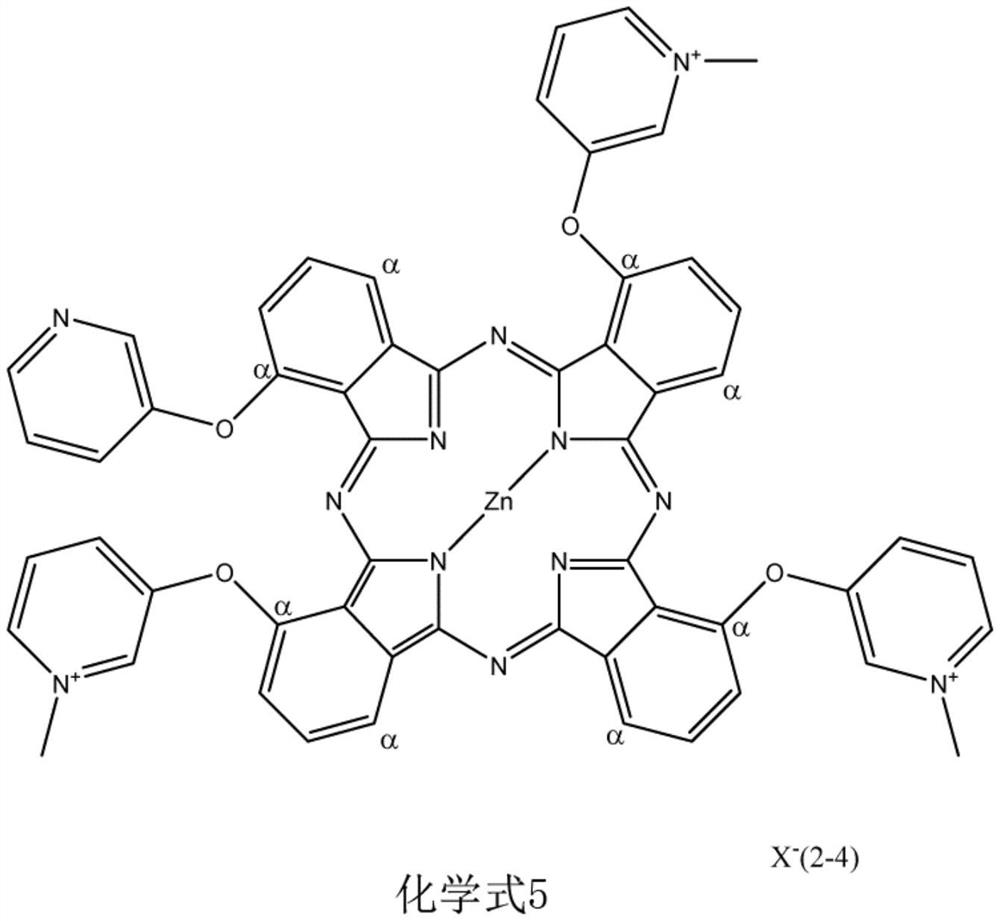

[0052] 1 g of the dye of Chemical Formula 1 was dissolved in 400 ml of water. 100 g of PVC powder were added with stirring. After 1 hour, the dye solid was filtered off. Dyed PVC (80 g) was added to a further 320 g of PVC powder and 260 g of dioctyl titanate was added. 130 g of DN300 diluent (CAS: 6846-50-0 from DYNAMIC CHEMICAL BINHAI INDUSTRY Co., Ltd.) was added, and the mixture was stirred for 1 hour. The glove mold was immersed in the liquid and dried in an oven at 180 °C for 3 minutes.

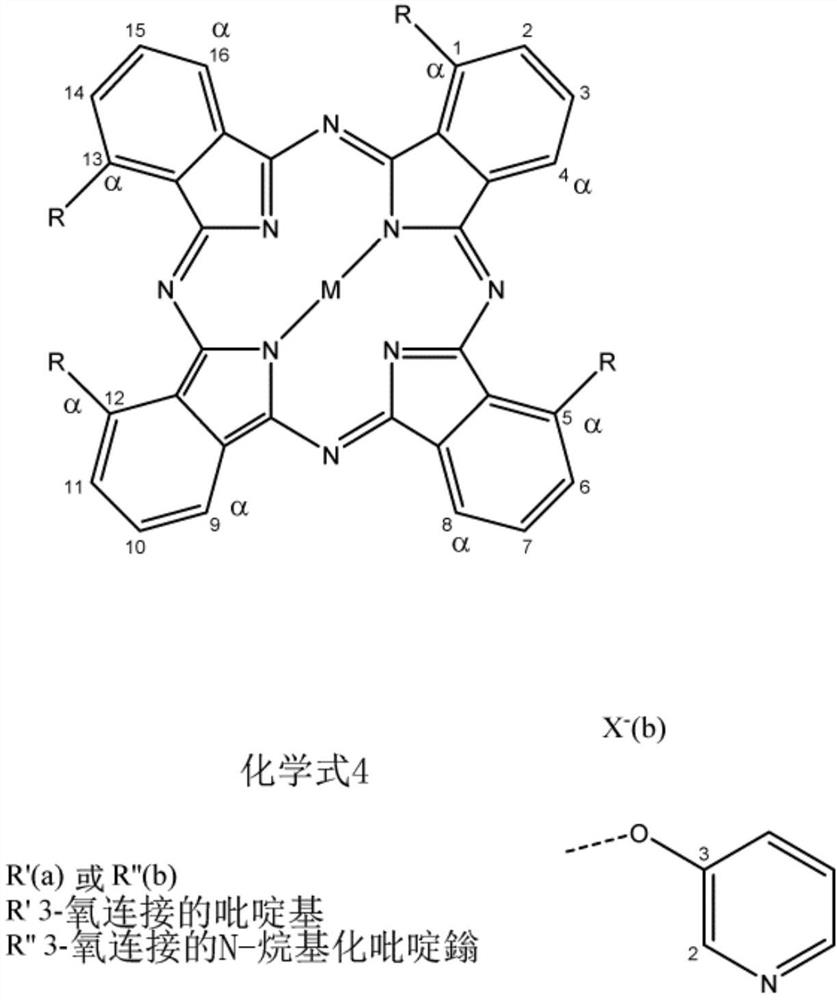

[0053] The membrane is transparent and analyzed by uv-vis in a Hach-DR3900 spectrophotometer by placing the membrane in the light path and running the spectrum in absorbance mode from 400nm to 800nm at 5nm intervals, which shows that the dye mainly Exist in monomeric form (the absorption at 680nm is the monomeric form of the dye). The peak at 680nm is monomeric and the peak at 640nm is from the aggregated form of phthalocyanine.

[0054]

[0055] The resulting films were tested...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com