Soil deep barrier repair technology and application thereof

A soil and deep layer technology, applied in the field of soil remediation, can solve the problems of heavy soil workload and cumbersome formation of barrier layers in saline-alkali land, and achieve the effects of simple operation, removal of barrier effect, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

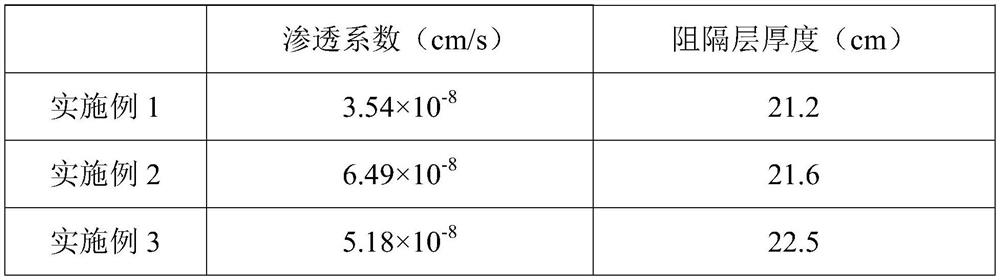

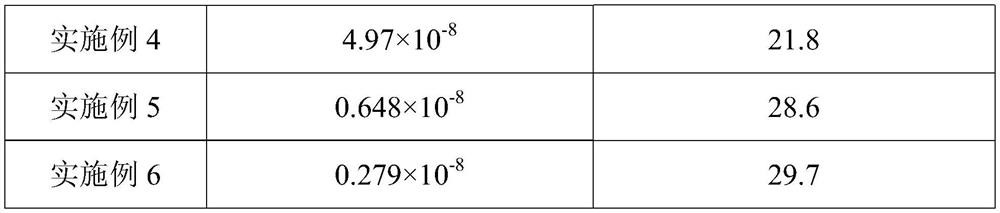

[0046] This embodiment provides a deep soil barrier restoration technology, comprising the following steps,

[0047] 1. Prepare the bacteria solution: based on the total volume of the bacteria solution, mix with water at the dosage of Bacillus Pasteurella bacteria powder 20g / L, ammonium sulfate 15g / L, and urea 10g / L, and use 0.1mol / L dilute Sulfuric acid and dilute ammonia water adjusted the pH of the culture medium to 7.5, and fermented and cultured at 35°C for 24 hours to obtain a carbonate mineralizing bacteria liquid;

[0048] 2. Prepare calcium ion solution: prepare calcium chloride aqueous solution at a concentration of 0.05mol / L;

Embodiment 2

[0051] This embodiment provides a deep soil barrier restoration technology, comprising the following steps,

[0052]1. Prepare bacterial solution: based on the total volume of the bacterial solution, mix it with water at the dosage of 20g / L of ordinary Desulfovibrio bacterial powder, 15g / L of ammonium sulfate, and 10g / L of urea, and use 0.1mol / L of dilute Sulfuric acid and dilute ammonia water adjusted the pH of the culture medium to 7.5, and fermented and cultured at 35°C for 24 hours to obtain a carbonate mineralizing bacteria liquid;

[0053] 2. Prepare calcium ion solution: prepare calcium chloride solution at a concentration of 0.05mol / L;

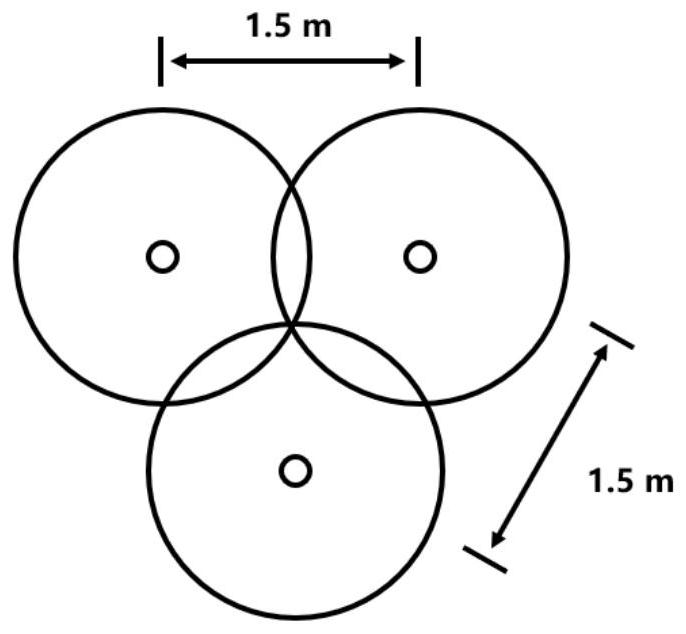

[0054] 3. On the soil to be repaired, according to the depth of 10m, 0.75m 3 Bacterial liquid and 0.75m 3 The calcium ion solution was laterally injected into it, the distance between the injection positions was 1.5m, and a barrier layer was formed after 28d.

Embodiment 3

[0056] This embodiment provides a deep soil barrier restoration technology, comprising the following steps,

[0057] 1. Prepare the bacterial solution: based on the total volume of the bacterial solution, mix with water at the dosage of Thiobacillus denitrificans bacteria powder 20g / L, ammonium sulfate 15g / L, and urea 10g / L, and use 0.1mol / L dilute Sulfuric acid and dilute ammonia water adjusted the pH of the culture medium to 7.5, and fermented and cultured at 35°C for 24 hours to obtain a carbonate mineralizing bacteria liquid;

[0058] 2. Prepare calcium ion solution: prepare calcium chloride solution at a concentration of 0.05mol / L;

[0059] 3. On the soil to be repaired, according to the depth of 10m, 0.75m 3 Bacterial liquid and 0.75m 3 The calcium ion solution was laterally injected into it, the distance between the injection positions was 1.5m, and a barrier layer was formed after 28d.

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmotic coefficient | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com