Liquid feeding centralized feeding control method for pig farm

A control method and technology for pig farms, which are applied in the directions of animal feeding devices, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problem of increasing the fixed investment burden of pig breeding enterprises, the threat of safe production of pig breeding enterprises, and the investment of construction costs. It can reduce the cost of auxiliary construction, reduce the use of drugs, and ensure safety and hygiene.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

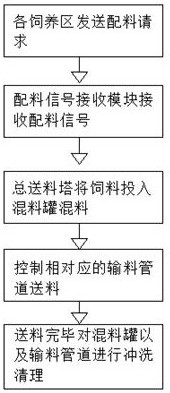

[0029] refer to Figure 1-2 , a method for controlling the centralized feeding of liquid feeding in a pig farm, comprising the following steps:

[0030] S1: Set up multiple feeding areas in the pig farm, each feeding area is equipped with feeding troughs, each feeding area is equipped with a batching signal transmission switch, and a general feeding tower is installed at the comparative position of multiple feeding areas , the batching signal receiving module is set in the main feeding tower, and the PLC is installed in the main feeding tower;

[0031] S2: Set up a mixing tank next to the main feeding tower. The output end of the mixing tank is divided into multiple feeding pipes through the split pipe. The feeding pipes are connected with the feeding troughs in each feeding area. The feeding area is entered into the PLC by number;

[0032] S3: each feeding area turns on the ingredient signal transmission switch to send the ingredient request;

[0033] S4: The batching sign...

Embodiment 2

[0042] refer to Figure 1-2 , a method for controlling the centralized feeding of liquid feeding in a pig farm, comprising the following steps:

[0043] S1: Set up multiple feeding areas in the pig farm, each feeding area is equipped with feeding troughs, each feeding area is equipped with a batching signal transmission switch, and a general feeding tower is installed at the comparative position of multiple feeding areas , the batching signal receiving module is set in the main feeding tower, and the PLC is installed in the main feeding tower;

[0044] S2: Set up a mixing tank next to the main feeding tower. The output end of the mixing tank is divided into multiple feeding pipes through the split pipe. The feeding pipes are connected with the feeding troughs in each feeding area. The feeding area is entered into the PLC by number;

[0045] S3: each feeding area turns on the ingredient signal transmission switch to send the ingredient request;

[0046] S4: The batching sign...

Embodiment 3

[0057] refer to Figure 1-2 , a method for controlling the centralized feeding of liquid feeding in a pig farm, comprising the following steps:

[0058] S1: Set up multiple feeding areas in the pig farm, each feeding area is equipped with feeding troughs, each feeding area is equipped with a batching signal transmission switch, and a general feeding tower is installed at the comparative position of multiple feeding areas , the batching signal receiving module is set in the main feeding tower, and the PLC is installed in the main feeding tower;

[0059] S2: Set up a mixing tank next to the main feeding tower. The output end of the mixing tank is divided into multiple feeding pipes through the split pipe. The feeding pipes are connected with the feeding troughs in each feeding area. The feeding area is entered into the PLC by number;

[0060] S3: each feeding area turns on the ingredient signal transmission switch to send the ingredient request;

[0061] S4: The batching sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com