Probiotic-flavored fermented milk without cane sugar and sweetening agent and preparation method of probiotic-flavored fermented milk

A technology of probiotics and sweeteners, applied in the field of probiotic flavored fermented milk and its preparation, can solve the problems of bitter taste and weak taste, achieve the effects of no bitterness, avoid over-breeding, and reduce the time of high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a method for preparing probiotic-flavored fermented milk without adding sucrose and sweeteners, comprising the following steps:

[0031] (1) Mix raw milk and fruit juice evenly to obtain material A;

[0032] (2) Material A is homogenized, sterilized, and cooled to obtain material B;

[0033] (3) Inoculate probiotics and starter in material B, mix material B, probiotics and starter evenly, and then ferment to obtain material C;

[0034] (4) Fill material C, cool and cook.

[0035] In the preparation method of the present invention, in step (1), the mixing conditions and methods are conventional conditions and methods in the art, preferably low temperature stirring and mixing. The mixing temperature is preferably 2-15°C, more preferably 6-8°C, most preferably 7°C. The mixing time is preferably 5-10 min, more preferably 7-9 min, most preferably 8 min.

[0036] In the preparation method of the present invention, in step (2), the homog...

Embodiment 1

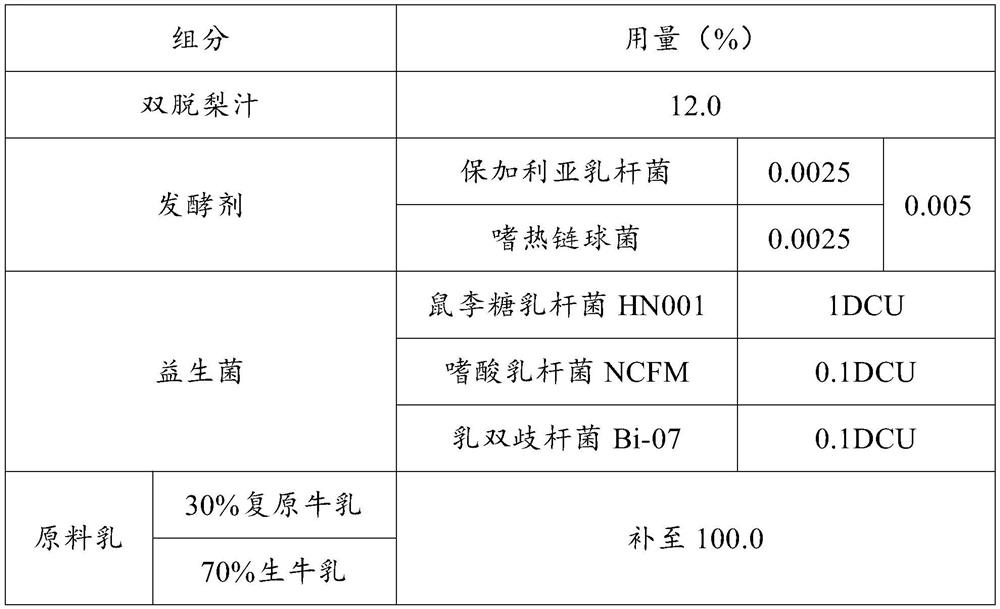

[0042] A kind of flavor fermented milk, it comprises raw material component and consumption (in terms of 100kg product) as shown in the following table::

[0043]

[0044] Preparation:

[0045] (1) According to the above ratio, mix double-dried apple juice with raw milk at 6°C, and stir for 10 minutes to obtain material A;

[0046] (2) Homogenize the material A, wherein the first-stage homogenization pressure is 16MPa, the second-stage homogenization pressure is 3MPa, and the homogenization temperature is 65°C. After homogenization, sterilize at 85°C for 10 minutes, and then cool to 45°C to obtain the material B;

[0047] (3) Inoculate probiotics and starter into material B at an inoculation temperature of 45°C, ferment at 45°C until the final acidity is 65°T, and the fermentation time is about 5 hours to obtain material C;

[0048] (4) Fill the material C at a filling temperature of 16°C, cool the fermented milk to 10°C and ripen it for 10 hours to obtain the product.

...

Embodiment 2

[0051] A kind of flavor fermented milk, it comprises raw material component and consumption (in 100kg product) as shown in the following table:

[0052]

[0053] Preparation:

[0054] (1) According to the above ratio, mix the Shuangtuo lychee juice with raw milk at 2°C, and stir for 5 minutes to obtain material A;

[0055] (2) Homogenize the material A, wherein the first-stage homogenization pressure is 17MPa, the second-stage homogenization pressure is 4MPa, and the homogenization temperature is 60°C. After homogenization, it is sterilized at 95°C for 5 minutes, and then cooled to 45°C to obtain the material B;

[0056] (3) Inoculate probiotics and starter into material B at an inoculation temperature of 37°C, ferment at 37°C until the final acidity is 70°T, and the fermentation time is about 8 hours to obtain material C;

[0057] (4) Fill the material C, the filling temperature is 25°C, cool the fermented milk to 6°C and ripen it for 15 hours to obtain the product.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com