Sliding rail machining method and product thereof

A processing method and technology of slide rails, applied in elevators, elevators in buildings, transportation and packaging, etc., can solve problems such as complex processing, serious environment, waste, etc., achieve high strength and precision, reduce operating noise, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

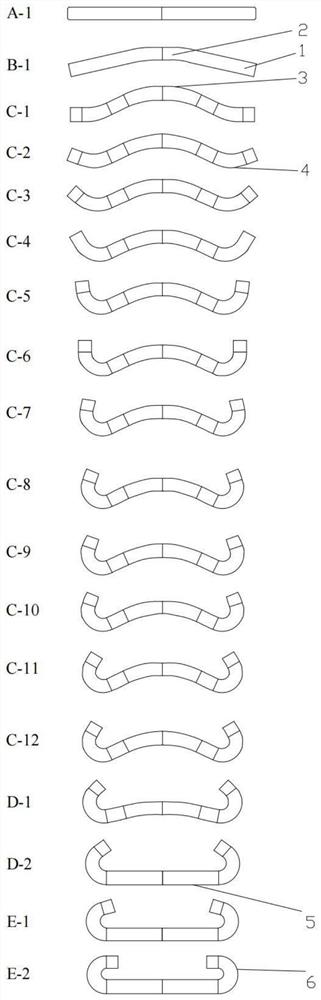

[0025] A kind of sliding rail processing method provided in this embodiment, such as figure 1 As shown, including step A. Select the steel plate with the required width and thickness, such as figure 1 As shown in step A-1;

[0026] Step B. Carry out rolling from the lower part of the center of the steel plate to form the base segment 2 with the two sides 1 protruding upwards, and the base segment 2 is provided with a first arc surface 3, such as figure 1 Rolling according to the steps shown in B-1, the formation of the first arc surface 3 can make the processing of the two sides 1 easier, so that when the two sides 1 are bent upwards, there is enough extension capacity in the middle, avoid as much as possible The reduction of intermediate strength ensures the strength of the product;

[0027] Step C. Roll the two sides 1 from the upper part of both sides, and the two sides 1 gradually extend upwards to form the second arc surface 4, such as figure 1 Rolling according to the...

Embodiment 2

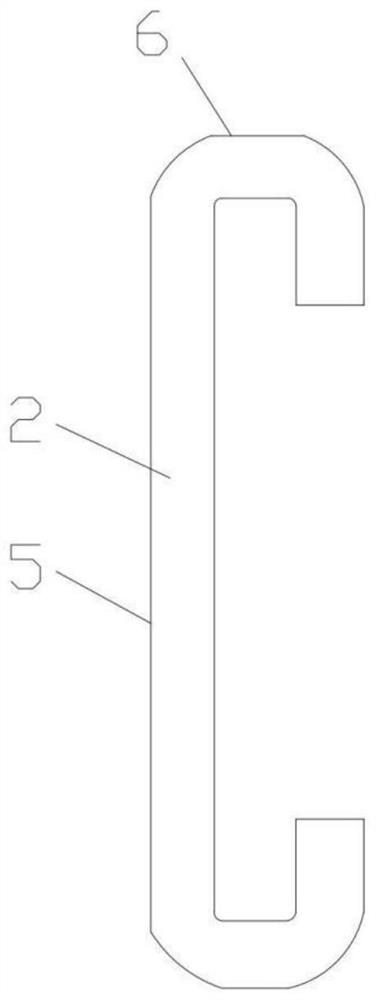

[0033] In the method for processing slide rails provided in this embodiment, in order to improve the strength, in addition to the features described in Embodiment 1, Step E is followed by Step F. Rolling the two sides 1 from the upper part until the two sides The side 1 ends towards the base segment 2 .

[0034] Such as image 3 As shown, the product obtained according to the method of this embodiment has lower processing difficulty, higher strength of the hanging wheel mounting surface 6, and better bearing capacity.

Embodiment 3

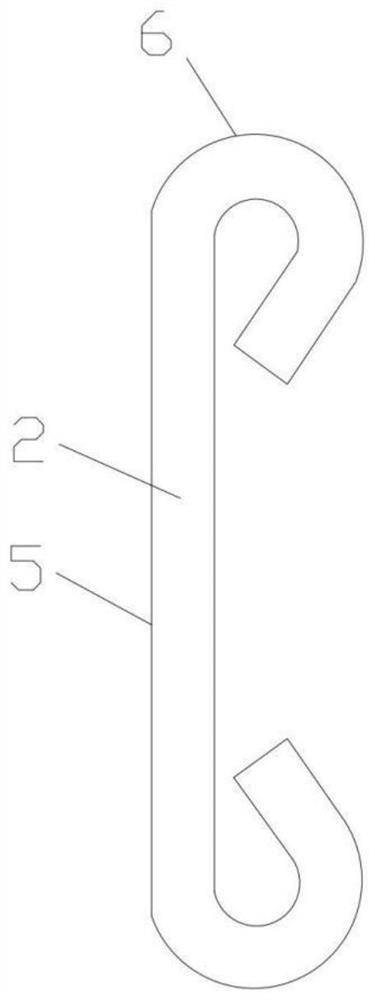

[0036] In the slide rail processing method provided in this embodiment, in order to improve the strength, in addition to the features described in Embodiment 2, the step F. is followed by step G. Bending the base body section 2 toward the direction of the two sides 1 Or rolling to form the first U-shaped side 7, and the two sides 1 are bent or rolled in the opposite direction. In this embodiment, the bending or rolling forming angle in step G. is 90 degrees, and the appearance is more beautiful.

[0037] Such as Figure 4 As shown, the product obtained according to the method of this embodiment has higher overall strength, and the mounting surface 6 of the hanging wheel can have a certain distance from the installation reference plane 5 of the slide rail, so as to avoid interference between the installation of the hanging wheel and the slide rail, and facilitate the installation of the hanging wheel .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com