Manufacturing process of lacquer painting with gold wires inlaid on surface

A production process and gold wire technology, which is applied in the direction of decorative art, art painting, etc., can solve the problems of poor practicability and small number of lacquer paintings, and achieve the effects of high yield, strong practicability, and improved fault tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

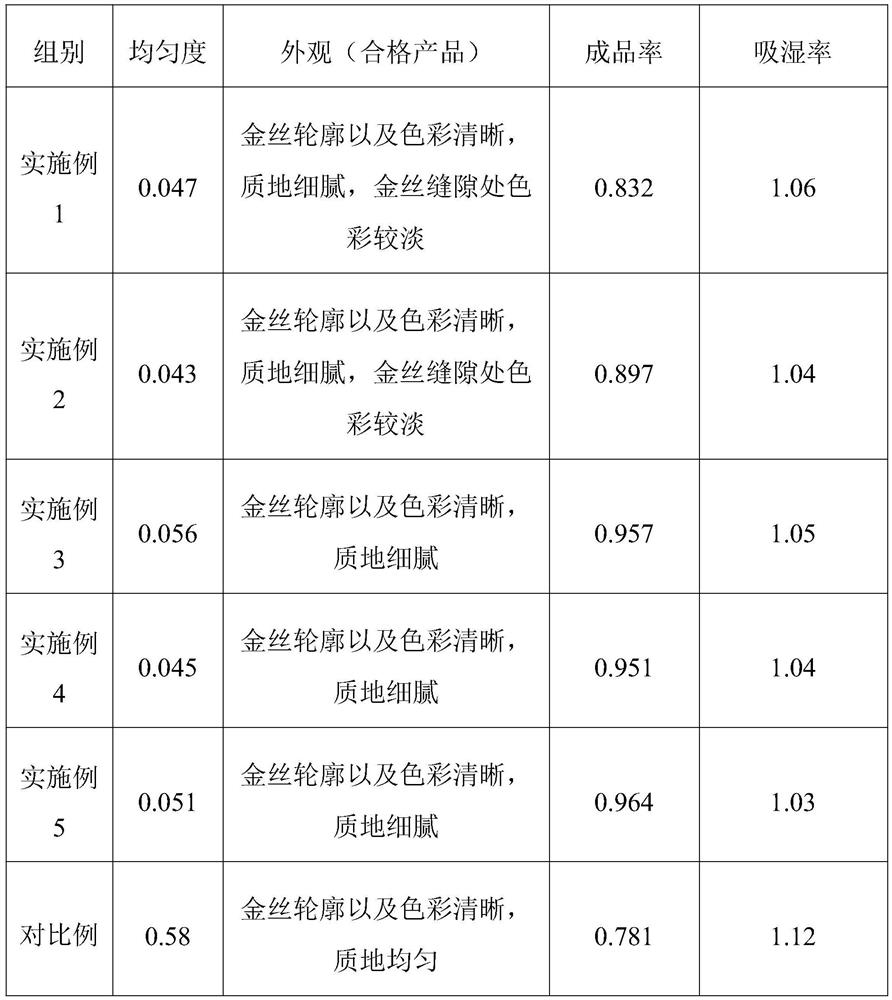

Examples

Embodiment 1

[0048] The purpose of this embodiment is to provide a lacquer painting production process inlaid with gold wires on the surface, comprising the following steps:

[0049] Mix raw lacquer, vermiculite, and chlorite at a mass ratio of 8:2.5:1, and stir for 12 minutes at a stirring speed of 250 rpm. After mixing, homogenize for 4 minutes under a pressure of 0.4 MPa to make a bottom Paint; polish the bottom plate under the pressure of 0.3MPa until the bottom plate is flat, apply the primer to the bottom plate, dry it at 35°C, and paste the prefabricated pattern with the bottom plate by silk screen printing to obtain prefab one;

[0050] Groove the gold wire inlaid position of preform 1, fill the groove with glue, insert the corresponding gold wire into the groove, solidify at room temperature, and grind under the pressure of 0.2MPa to obtain the preform Product two; wherein the adhesive is a commercially available transparent adhesive;

[0051] Coat the corresponding position of ...

Embodiment 2

[0053] The purpose of this embodiment is to provide a lacquer painting production process inlaid with gold wires on the surface, comprising the following steps:

[0054] Mix raw lacquer, vermiculite, and chlorite at a mass ratio of 7:2:1, and stir for 15 minutes at a stirring speed of 200 rpm. After mixing, homogenize for 5 minutes under a pressure of 0.3 MPa to make a bottom Paint; polish the bottom plate under the pressure of 0.3MPa until the bottom plate is flat, apply the primer to the bottom plate, dry it at 35°C, and glue the prefabricated pattern to the bottom plate. get prefab one;

[0055] Make a groove at the gold wire inlay position of preform 1, fill the groove with glue, insert the corresponding gold wire into the groove, cure at 35°C, and then grind it under the pressure of 0.15MPa Finally, a preform 2 is obtained; wherein the glue is made by mixing polypropylene and epoxy resin, and the mass ratio of polypropylene and epoxy resin is 1:1;

[0056] Coat the corr...

Embodiment 3

[0058] The purpose of this embodiment is to provide a lacquer painting production process inlaid with gold wires on the surface, comprising the following steps:

[0059] Mix raw lacquer, vermiculite, and chlorite at a mass ratio of 9:3:1, and stir for 10 minutes at a stirring speed of 300 rpm. After mixing, homogenize for 3 minutes under a pressure of 0.5 MPa to make a bottom Paint; polish the bottom plate under the pressure of 0.35MPa until the bottom plate is flat, apply the primer to the bottom plate, dry it at 40°C, and attach the prefabricated pattern to the bottom plate by digital printing. get prefab one;

[0060] Make a groove at the gold wire inlay position of preform 1, fill the groove with glue, insert the corresponding gold wire into the groove, cure it at 45°C, and then grind it under the pressure of 0.25MPa Finally, a preform 2 is obtained; wherein the glue is made by mixing kaolin, polypropylene and epoxy resin, and the mass ratio of kaolin, polypropylene and e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap