Dendrobium wine cellar storage, assembly and sealing production line

A production line and sealing technology, which is applied in the directions of packaging sealing/fastening, packaging, transportation packaging, etc., can solve the problems of time-consuming and labor-intensive, and cannot achieve full automation of the production line, and achieve the effects of reducing production costs, facilitating long-term storage, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

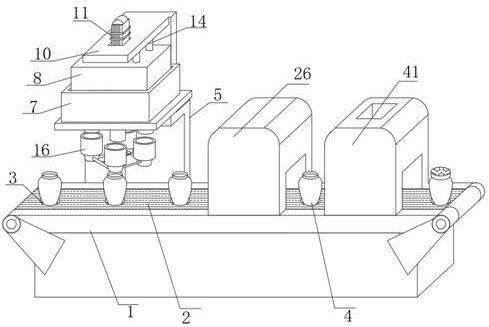

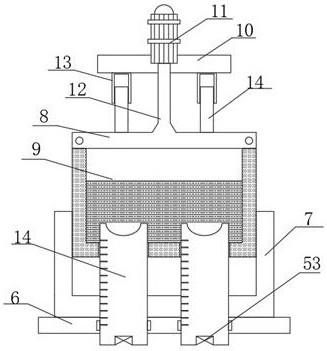

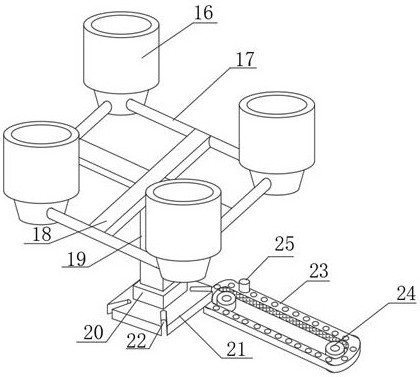

[0032] Such as Figure 1-7 As shown, a Dendrobium wine cellar assembly and sealing production line includes a stepping conveyor 1, a conveyor belt 2 is arranged on the double chain of the stepping conveyor 1, and the surface of the conveyor belt 2 is equidistantly provided with placement grooves 3, and placement grooves 3 A wine tank 4 is placed inside, a bracket 5 is fixedly installed near the left end of the stepping conveyor 1, a support 6 is arranged horizontally in the middle of the bracket 5, and a lifting groove 7 is fixedly installed on the bearing 6, and the lifting groove 7 is movable A large wine vat 8 is provided, and the large wine vat 8 includes a wine storage chamber 9, a top seat 10 is arranged horizontally on the upper end of the support 5, a cylinder 11 is installed on the top seat 10, and a lifting rod 12 is arranged downward on the cylinder 11 to lift The lower end of the rod 12 and the central position of the large wine vat 8 are fixed, four groups of slid...

Embodiment 2

[0039] Such as Figure 4-6 As shown, after assembly, the wine tank 4 moves into the sealing mechanism 26, the wine tank 4 is located at the lower end of the receiving tank 29, and the arc-shaped sealing frame 27 moves in a circle. When the contact 40 and the outer surface of the arc-shaped sealing frame 27 When in contact, the spring 38 moves to the other side in the spring limiting sleeve 39, and acts on the lifting plate 36 to lift the lifting plate 36, and the lifting plate 36 sends the paper film 34 on its surface from the discharge port 35, and the paper film 34 enters the receiving tank 29 and quickly falls on the receiving step 30, and is stained with some glue. At this time, it touches the mouth of the wine tank 4, and the paper film 34 is attached to the mouth of the tank. Continue to rotate, and the paper film 34 contacts with the bundle edge baffle 31 in the receiving chute 29, and the bundle edge baffle 31 folds the periphery of the paper film 34 to prevent the fol...

Embodiment 3

[0041] Such as Figure 7 As shown, after the wine tank 4 is filmed, it moves into the mud covering mechanism 41, and the thick mud in the mud bucket 42 falls from the upper port 45 and then fills up the mud transporting tank 49, which rotates with the mud transporting at a constant speed. The wheel 47 moves to the lowest end, releases the thick mud from the lower port 46, and enters the material guide pipe 50. At the same time, the hydraulic door closer 52 drives the four sets of arc-shaped splints 51 to close to form a seal on the tank mouth. , and then the thick mud in the feed pipe 50 falls to the mouth of the tank to cover, and then preheats with the surrounding heaters to solidify the thick mud to prevent falling off from the mouth of the tank and complete the task of covering mud.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com