Large-diameter deep hole blasting method suitable for coal mine collapse column passing

A technology of deep hole blasting and collapsing column, applied in blasting and other directions, can solve the problems of many blasting cycles, material consumption, slow advancing speed, etc., to reduce production costs, prevent potential safety hazards, and increase rock cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

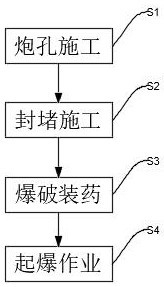

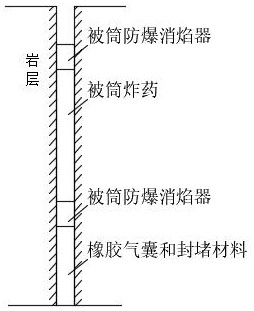

[0024] see Figure 1-2 , the present invention provides a technical solution: a large-diameter deep hole blasting method suitable for collapsing pillars in coal mines, the specific steps are as follows:

[0025] S1. Blasting hole construction: Drill multiple blasting holes along the radial direction of the subsidence column in geological exploration. The blasting holes are parallel to the fully mechanized mining face. At the center of the subsidence column, the actual perforation depth of the blasthole is designed according to the radial length of the subsidence column in geological exploration; the number of blastholes is 5, and the distance between the blastholes is 2m; the diameter of the blasthole is 94m, made of alloy steel The drilling rig for drill bit is used for blast hole construction;

[0026] S2. Plugging construction: fill the blast hole with plugging material and rubber airbag in sequence; the plugging material is high-viscosity rubber material, the filling thic...

Embodiment 2

[0030] refer to Figure 1-2 , the present invention provides a technical solution: a large-diameter deep hole blasting method suitable for collapsing pillars in coal mines, the specific steps are as follows:

[0031] S1. Blasting hole construction: Drill multiple blasting holes along the radial direction of the subsidence column in geological exploration. The blasting holes are parallel to the fully mechanized mining face. At the center of the subsidence column, the actual perforation depth of the blasthole is designed according to the radial length of the subsidence column in geological exploration; the number of blastholes is 5, and the distance between the blastholes is 3m; the diameter of the blasthole is 94m, made of alloy steel The drilling rig for drill bit is used for blast hole construction;

[0032] S2. Plugging construction: fill the blast hole with plugging material and rubber air bag in sequence; the plugging material is high-viscosity rubber material, the fillin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com