Contact-free workpiece surface quality inspection device

A technology for workpiece surface and quality inspection, applied in measuring devices, optical devices, instruments, etc., can solve the problems of unqualified workpiece separation and transmission, workpiece scratches, affecting electroplating quality, etc., to improve practicability and performance, The effect of improving efficiency and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

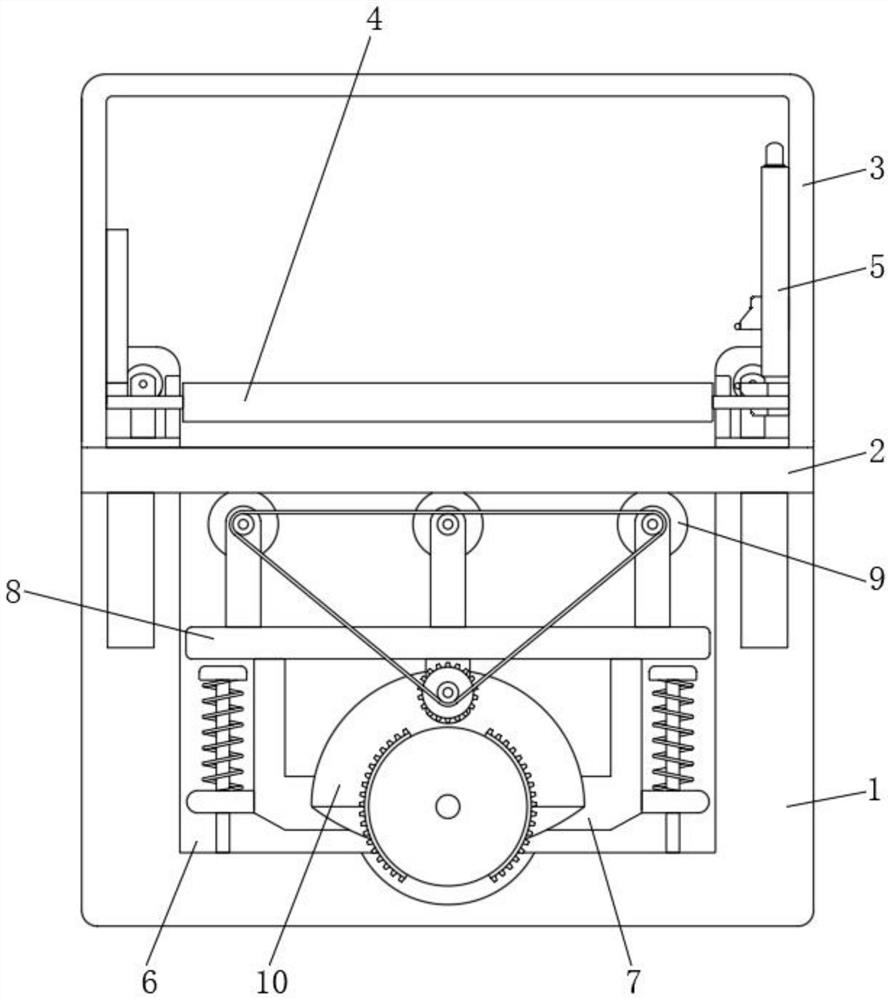

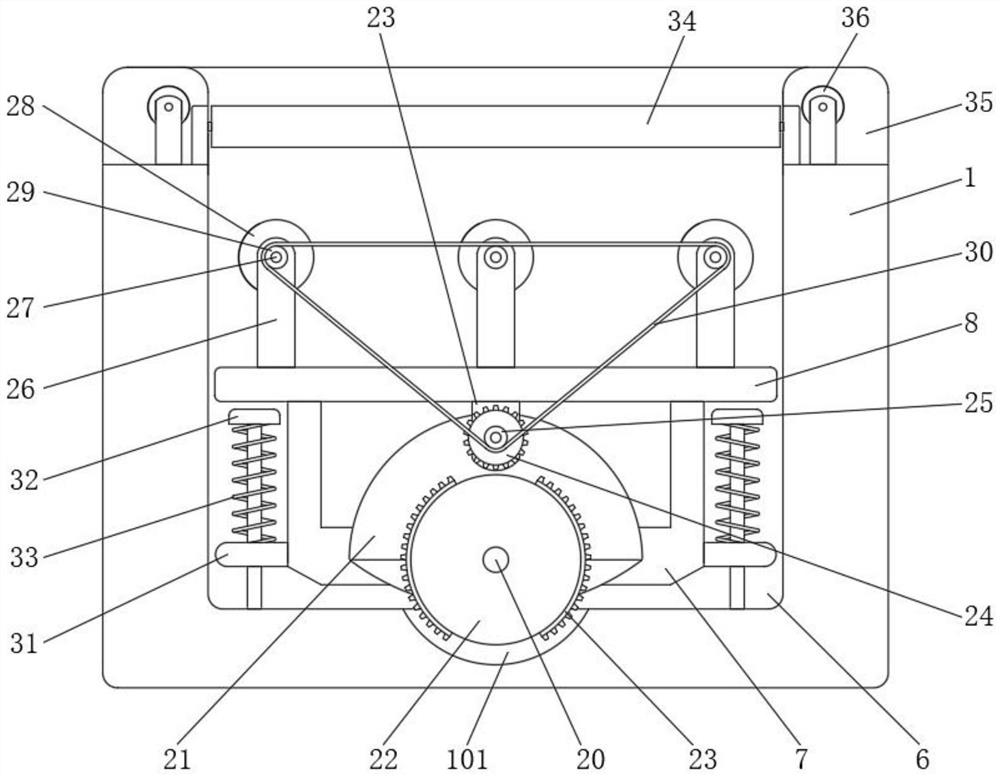

[0036] Embodiment one, by Figure 1 to Figure 8 Given, the present invention includes a fixed plate 2 fixedly installed on one side of the base 1, an n-shaped frame 3 fixedly installed on the top of the fixed plate 2, and two first rollers 4 installed on the lower part of the inner side of the n-shaped frame 3, n The middle part of the inner lower part of the shaped frame 3 is equipped with a test end 5, the test end 5 is located between the two first rollers 4, the middle part of the base 1 is provided with a groove 6, and the bottom of the groove 6 is equipped with a U-shaped lifting plate 7, A mounting plate 8 is fixedly installed between the tops of the U-shaped lifting plate 7, and a transmission assembly 9 is installed between both sides of the mounting plate 8 top, and a power end 10 is installed in the middle of the U-shaped lifting plate 7, and the two sides of the power end 10 The ends are respectively connected to the two transmission components 9 by transmission; ...

Embodiment 2

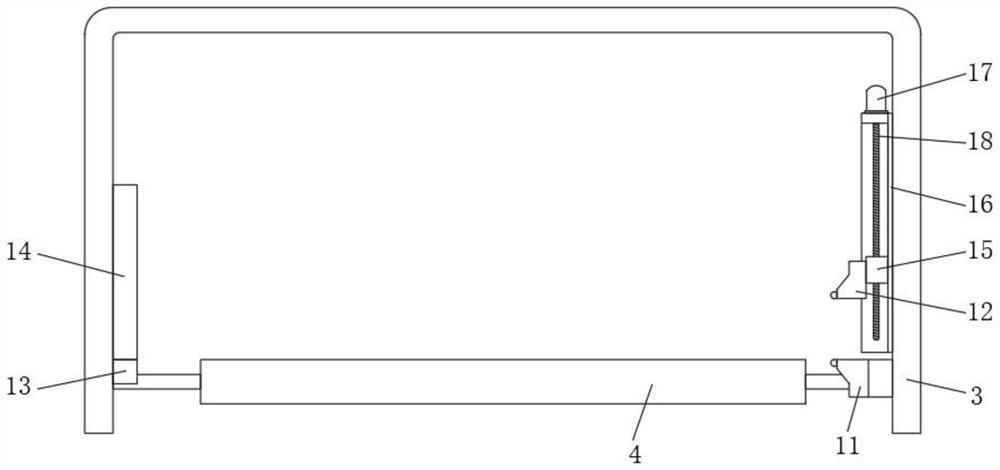

[0040] Embodiment two, on the basis of embodiment one, by figure 2 Provided, the inspection terminal 5 includes a fixed infrared ray transmitter 11, a mobile infrared ray transmitter 12, a first infrared receiver 13 and a second infrared receiver 14, and the fixed infrared transmitter 11 and the mobile infrared transmitter 12 are installed on the n-shaped frame 3 The bottom of the inner two sides, the first infrared receiving end 13 and the second infrared receiving end 14 are installed in the middle of both sides of the n-shaped frame 3, the fixed infrared emitting end 11 and the mobile infrared emitting end 12 and the first infrared receiving end 13 and The second infrared receiving end 14 is a dislocation installation, and the fixed infrared emitting end 11, the mobile infrared emitting end 12, the first infrared receiving end 13 and the second infrared receiving end 14 are all controlled by the controller, and the detected information is all transmitted to the controller. ...

Embodiment 3

[0042] Embodiment three, on the basis of embodiment one, by Figure 3 to Figure 5 as well as Figure 7 and Figure 8 Given, the power end 10 includes a double output shaft motor 19, two rotating shafts 20 and two jacking discs 21, the double output shaft motor 19 is installed in the middle of the U-shaped lifting plate 7, and the two rotating shafts 20 are installed on the double output shaft motor 19, and one end of the rotating shaft 20 respectively extends to the two ends of the U-shaped lifting plate 7 and is fixedly connected with two jacking plates 21, so that the U-shaped lifting plate 7 can be effectively adjusted; the jacking plate 21 includes The half disc 2101 and the crescent plate 2102, the crescent plate 2102 is fixedly installed in the middle of the half disc 2101, and the half disc 2101 and the crescent plate 2102 are all fixedly installed on the end of the rotating shaft 20, the arc surface of the crescent plate 2102 and the concave The bottom of the groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com