Sample pressing equipment for foundation reinforcement

A foundation reinforcement and foundation technology, which is applied in the preparation of test samples, foundation structure engineering, and on-site foundation soil survey, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

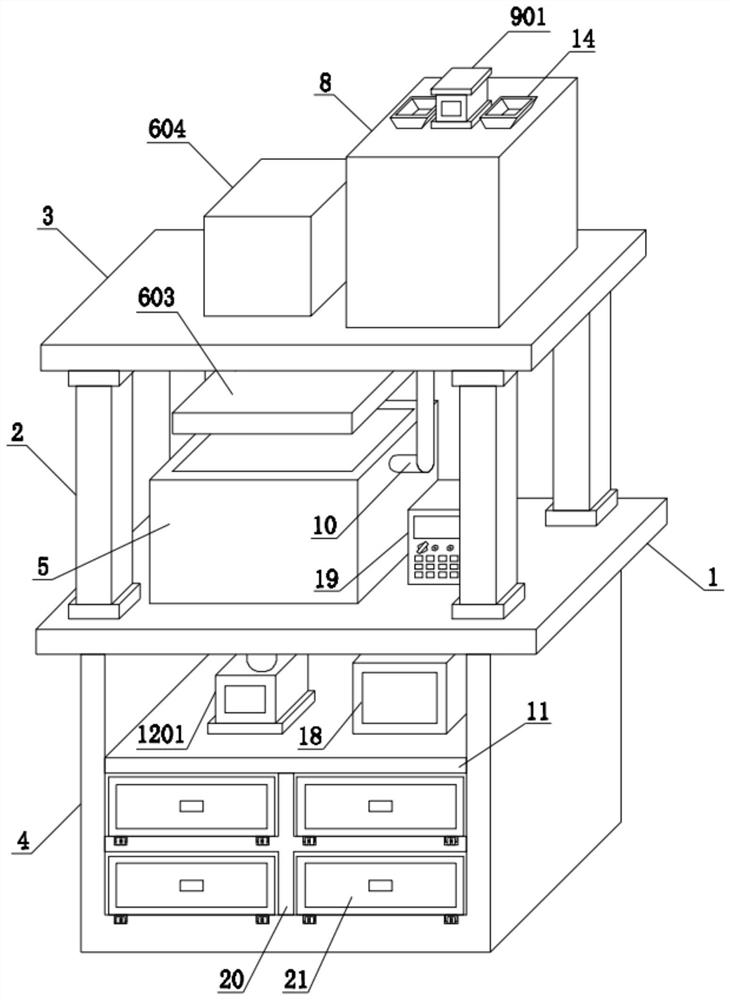

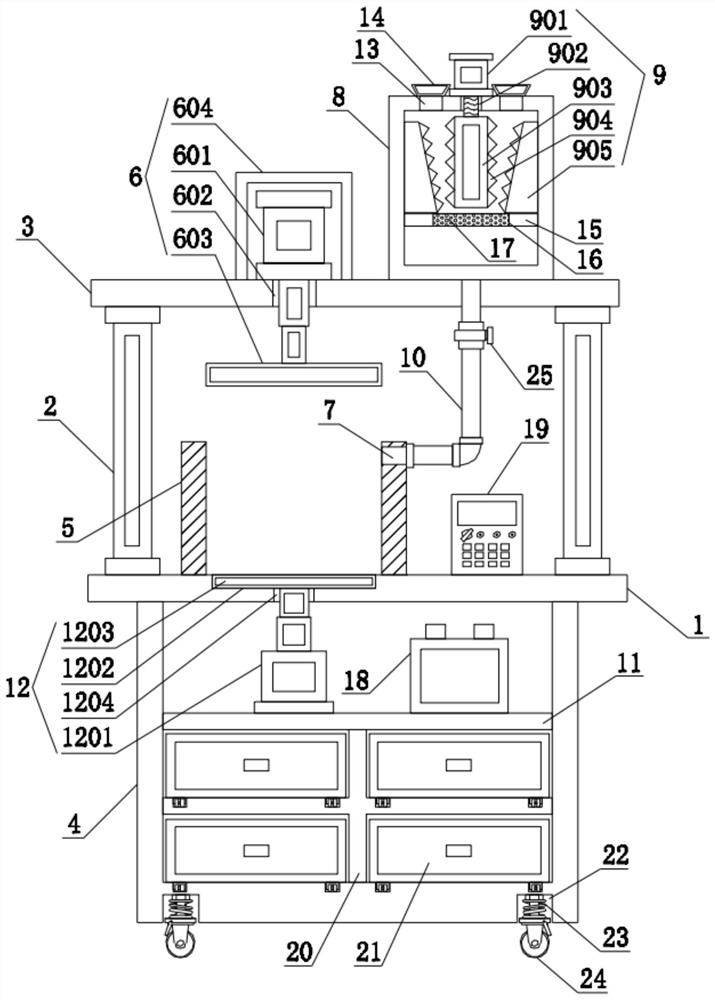

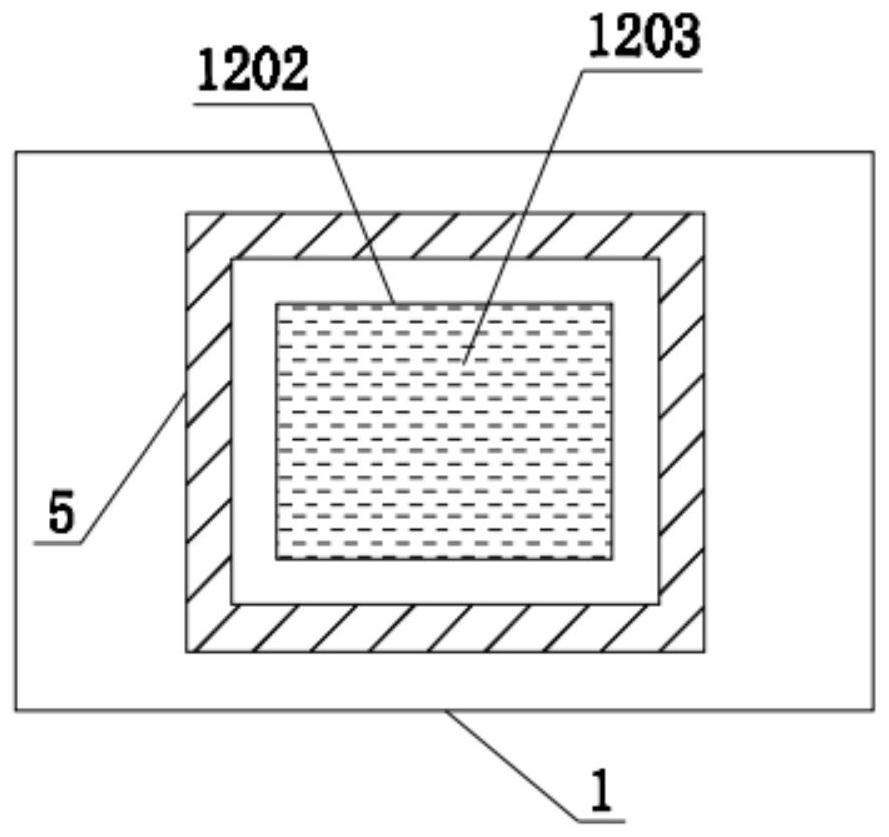

[0039] see Figure 1-8 , a kind of pressure sample equipment for foundation reinforcement, comprising a workbench 1, the four corners of the top of the workbench 1 are fixedly connected with connecting columns 2, the tops of the connecting columns 2 are fixedly installed with a top plate 3, the bottom of the workbench 1 A bearing box 4 is fixedly connected, a compacting frame 5 is fixedly connected to the left side of the top of the workbench 1, and a pressing mechanism 6 is fixedly installed on the top of the top plate 3 corresponding to the compacting frame 5, and the right side of the compacting frame 5 The upper end is provided with a feeding port 7, and the right side of the top of the top plate 3 is fixedly connected with a crushing box 8, and a crushing mechanism 9 is fixedly installed inside the crushing box 8, and a discharge pipe 10 is fixedly installed at the bottom of the crushing box 8, and the discharge pipe 10 The other end passes through the top plate 3 and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com