Determination method for dynamic loading capacity of affinity chromatography filler

A technology of chromatography filler and determination method, which is applied in chemical instruments and methods, analytical materials, material separation, etc., can solve the problems of large material consumption, long process time, and long processing cycle, and achieve simple model calculation and low material cost. Low, time and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

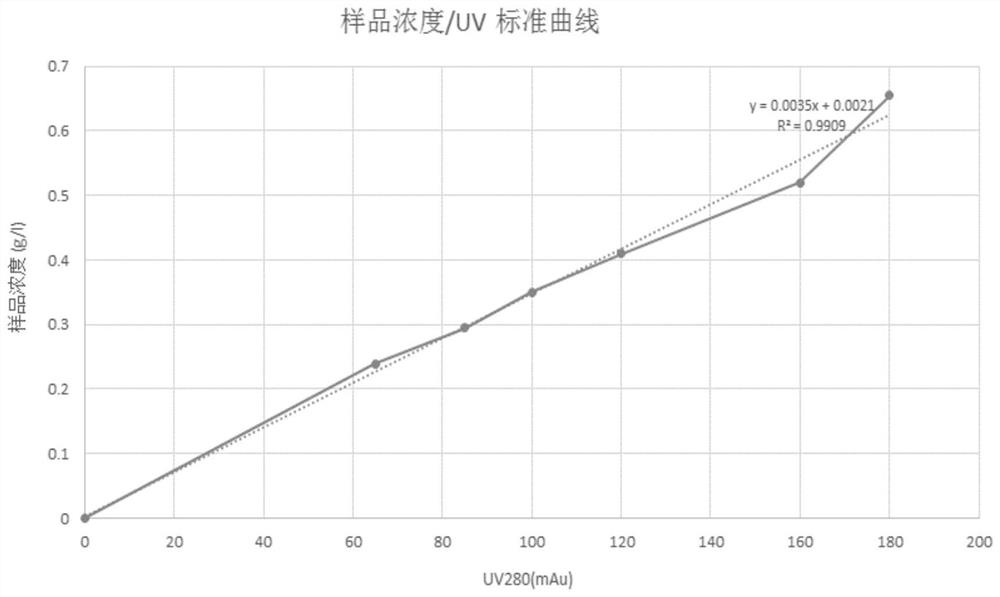

[0035] The method for determining the dynamic capacity of the affinity chromatography filler in this embodiment first utilizes the affinity chromatography filler to fit the sample concentration-ultraviolet absorbance value standard curve, specifically, including the following steps:

[0036] In step 1), the protein purified by affinity chromatography is diluted to the target protein concentration of 2.4 g / l in a normal fermentation broth with an affinity chromatography balance solution.

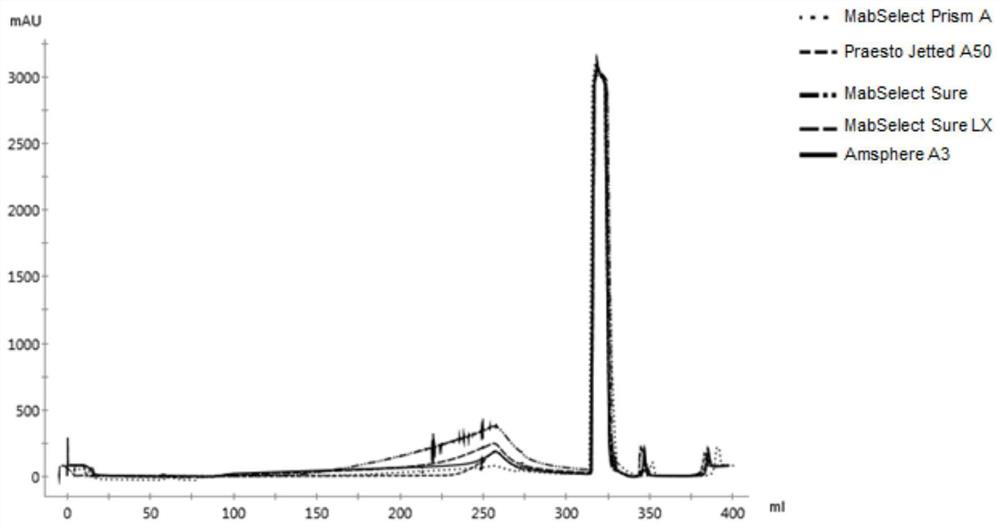

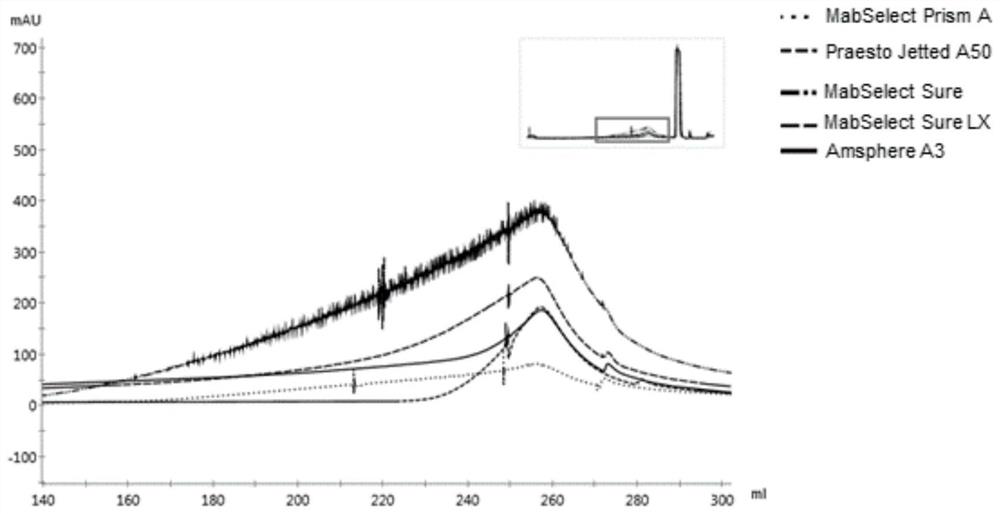

[0037] Step 2), prepare an affinity chromatography filler (Amsphere TM A3) Chromatographic column, use affinity chromatography equilibrium buffer (20mmol / L phosphate+100mmol / L NaCl, pH7.3±0.2, conductivity 13.0±2.0mS / cm) to replace the preservation in the affinity chromatography filler Solution (100mmol / L acetate+2% benzyl alcohol buffer, pH5.0±0.2, conductivity 4.5±1.0mS / cm) and equilibrated affinity chromatography filler.

[0038] Step 3), the sample prepared in step 1) is loaded into ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com