Environment-friendly building construction dust falling equipment

A kind of construction and environmental protection technology, applied in the direction of construction, building structure, building materials, etc., can solve the problems of poor dust suppression efficiency and dust suppression effect, time-consuming and laborious, etc., to prevent dust from flying, simple operation, and improve dust suppression effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

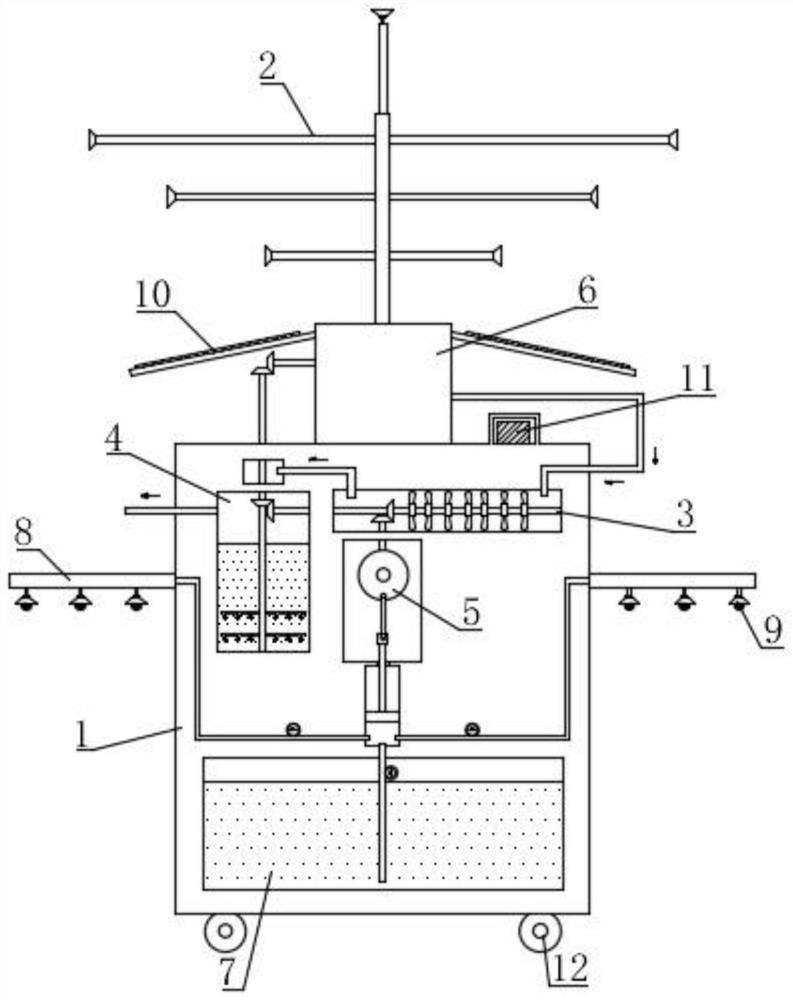

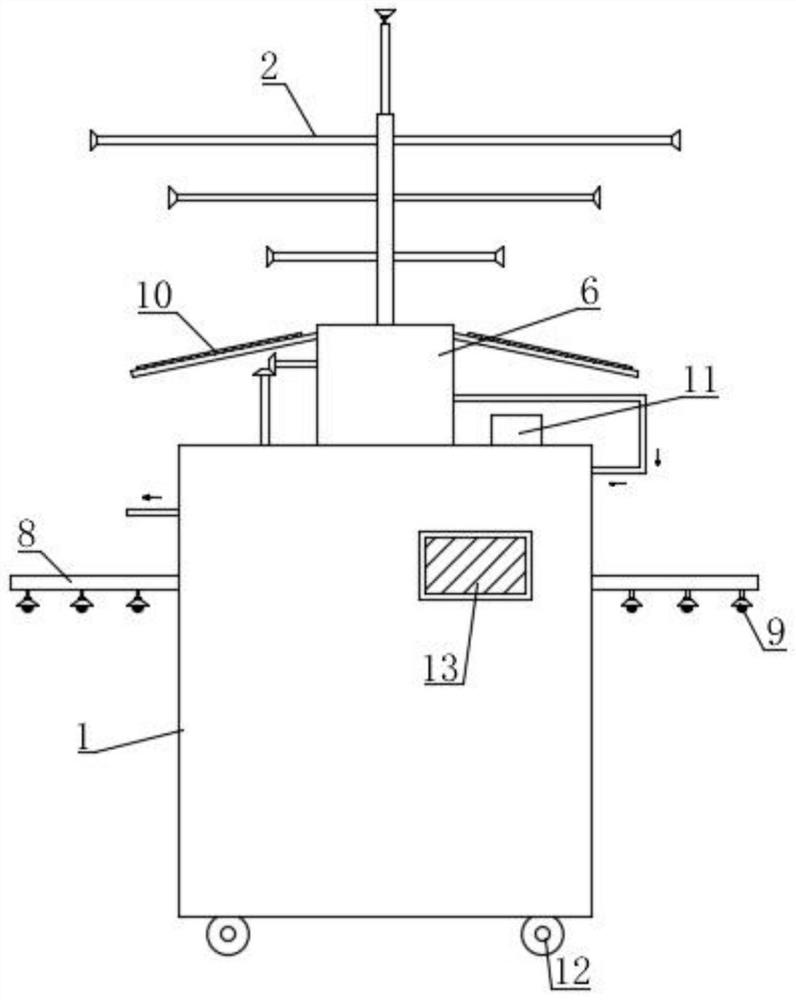

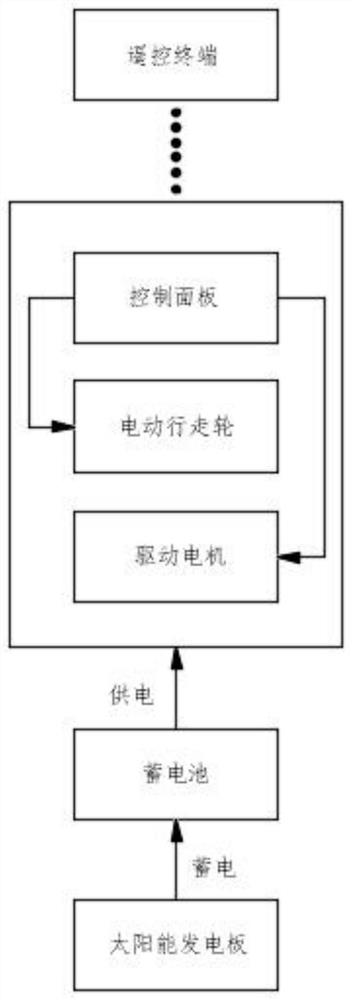

[0050] Such as Figure 1-10 As shown, a kind of environment-friendly building construction dust suppression equipment proposed by the present invention includes a dust suppression equipment box 1, and an electric traveling wheel 12 is installed on the bottom of the dust suppression equipment box 1, and the electric traveling wheel 12 is driven by electric power to realize the movement of the equipment and the dust suppression. The inside of the equipment box 1 is provided with a water storage chamber 7, and the top of the dust suppression equipment box 1 is fixed with a dust removal box 6 by bolts, and the dust removal box 6 is equipped with a high-efficiency dust collection component 2, and a secondary dust removal unit is installed in the dust suppression equipment box 1. Component 4, the dust removal equipment box 1 is equipped with an air extraction and conveying assembly 3, and the air extraction and conveying assembly 3 is used to transport the gas in the dust removal box...

Embodiment 2

[0056] Such as figure 1 with Figure 4-8 As shown, the difference between this embodiment and Embodiment 1 is that a drive motor 503 is fixedly installed on the dust suppression equipment box 1 through a motor base, and the drive motor 503 is controlled to start and close by the control panel 13, which is convenient for control, and the drive motor 503 The output end is connected with the drive shaft 502, and the first transmission rod 36 installed vertically is rotated on the dust reduction equipment box 1, and the top end of the first transmission rod 36 is meshed with the air supply shaft 32 through a bevel gear, and the drive shaft 502 The bevel gear is engaged with the bottom end of the first transmission rod 36; the air supply shaft 32 extends into the liquid dust removal chamber 41, and the air supply shaft 32 is engaged with the second hollow shaft 43 through the bevel gear for transmission connection. The second transmission rod 62 is rotatably installed, and the top...

Embodiment 3

[0059] Such as Figure 4 with Figure 11-12 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that the first hollow rotating shaft 21 is equipped with a horizontally arranged striking and anti-blocking hole assembly 14, and the striking and anti-blocking hole assembly 14 is located in the dust removal box 6. And the anti-blocking hole assembly 14 includes a limit tube 141 and a telescopic rod 144, the limit tube 141 is horizontally installed on the first hollow rotating shaft 21, a limit slider 142 and a spring 143 are installed in the limit tube 141, and the spring 143 Connected with the limit slider 142, the telescopic rod 144 is horizontally set and inserted into the limit cylinder 141, the telescopic rod 144 is connected with the limit slider 142, and the end of the telescopic rod 144 away from the limit cylinder 141 is equipped with a rubber ball 145, the rubber ball 145 The ball 145 is in contact with the vertical dust filter net 61; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com