Composite die pipe for alloy ingot pouring

A composite mold and alloy ingot technology, applied in the field of superalloy smelting, can solve the problems of slow solidification of molten steel, low heat dissipation efficiency, uneven composition of alloy ingots, etc., to improve surface quality and purity, improve composition uniformity, The effect of improving the quality of the inner surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

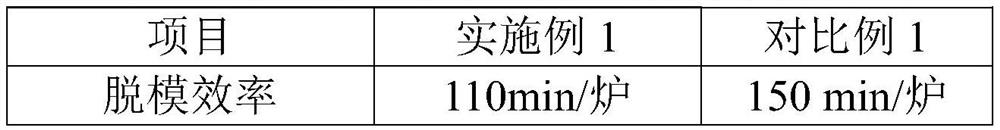

[0021] Embodiment 1 (preparation of φ 50mm master alloy ingot)

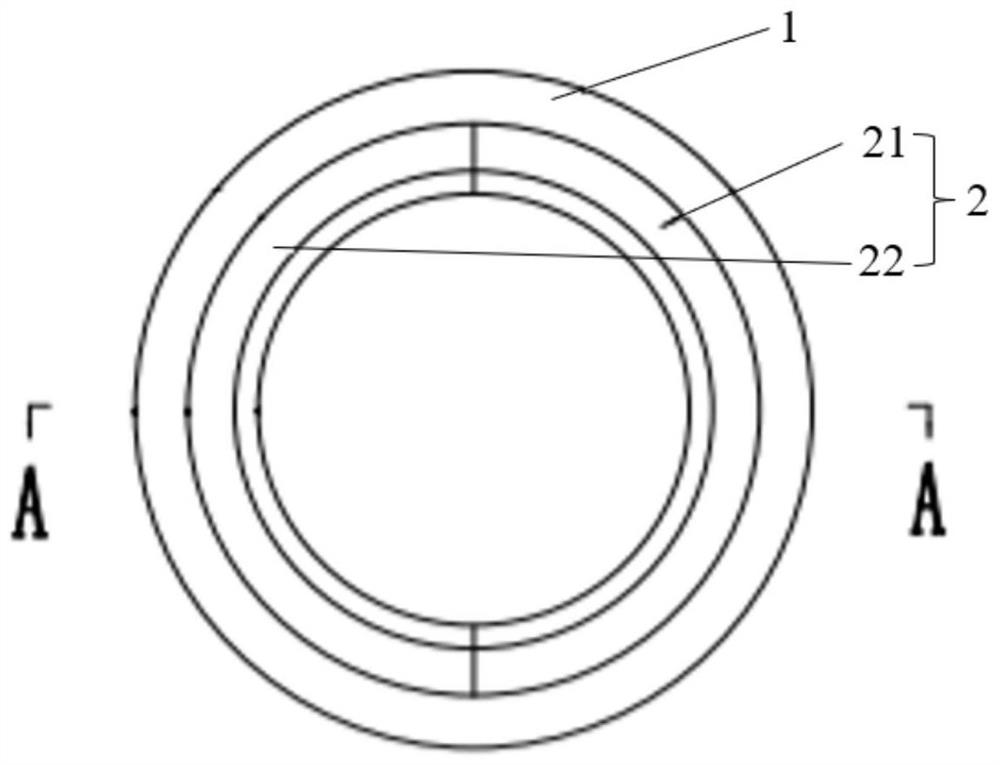

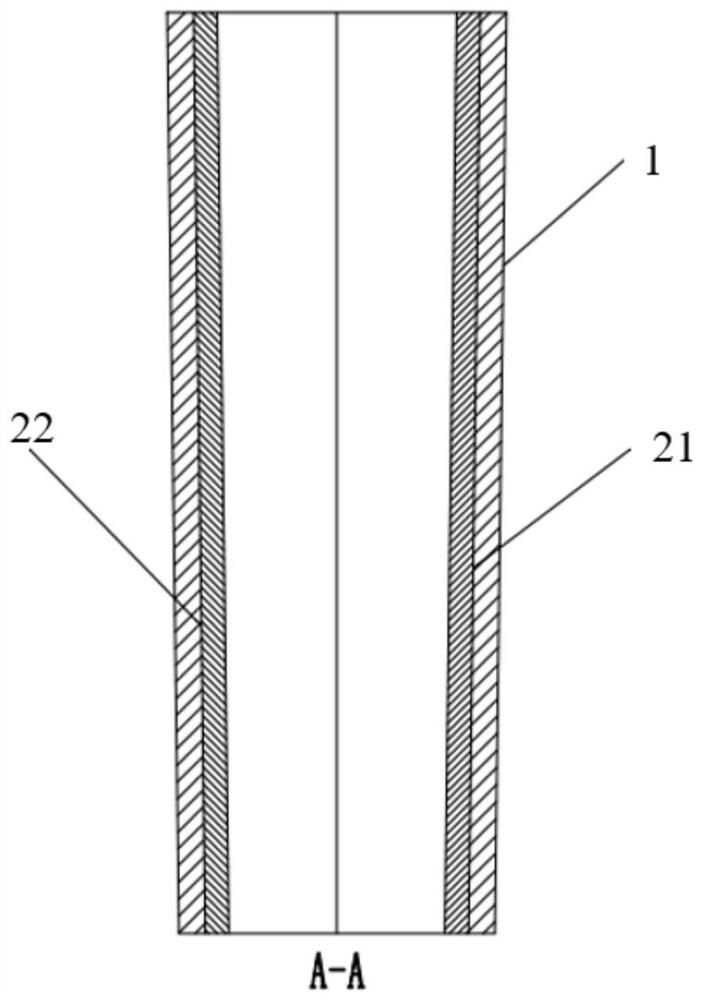

[0022] Such as figure 1 and 2 Shown, a kind of composite mold tube for alloy ingot pouring, described composite mold tube comprises outer layer cylindrical mold tube 1 and inner layer cylindrical mold tube 2, and described inner layer cylindrical mold tube 2 consists of two The semicircular mold tube 21, 22 is composed of, the inner cylindrical mold tube 2 is arranged inside the outer cylindrical mold tube 1, and the outer surface of the inner cylindrical mold tube 2 and the outer layer The inner surface of the cylindrical mold tube 1 is in close contact with each other.

[0023] The outer cylindrical mold tube 1 and the inner cylindrical mold tube 2 are made of carbon steel.

[0024] The length of the outer cylindrical mold tube 1 and the inner cylindrical mold tube 2 is 800mm, the wall thickness is 5mm, the taper is 0°, and the inner diameter of the two semicircular inner wall mold tubes is 50mm.

[0025] T...

Embodiment 2

[0028] Embodiment 2 (preparation of φ80mm master alloy ingot)

[0029] A composite mold tube for casting alloy ingots, the composite mold tube includes an outer cylindrical mold tube 1 and an inner cylindrical mold tube 2, and the inner cylindrical mold tube 2 consists of two semicircular mold tubes Die tube 21, 22 is formed, and described inner cylindrical mold tube 2 is arranged on the inside of described outer cylindrical mold tube 1, and the outer surface of described inner cylindrical mold tube 2 and outer cylindrical shape The inner surface of the mold tube 1 is in close contact with each other.

[0030] The outer cylindrical mold tube 1 and the inner cylindrical mold tube 2 are made of carbon steel.

[0031] The length of the outer cylindrical mold tube 1 and the inner cylindrical mold tube 2 is 1000mm, the wall thickness is 5mm, the taper is 1°, and the inner diameter of the two semicircular inner wall mold tubes is 80mm.

[0032] The inner surface roughness of the o...

Embodiment 3

[0036] Embodiment 3 (preparation of φ 120mm master alloy ingot)

[0037] A composite mold tube for casting alloy ingots, the composite mold tube includes an outer cylindrical mold tube 1 and an inner cylindrical mold tube 2, and the inner cylindrical mold tube 2 consists of two semicircular mold tubes Die tube 21, 22 is formed, and described inner cylindrical mold tube 2 is arranged on the inside of described outer cylindrical mold tube 1, and the outer surface of described inner cylindrical mold tube 2 and outer cylindrical shape The inner surface of the mold tube 1 is in close contact with each other.

[0038] The outer cylindrical mold tube 1 and the inner cylindrical mold tube 2 are made of carbon steel.

[0039] The length of the outer cylindrical mold tube 1 and the inner cylindrical mold tube 2 is 900mm, the wall thickness is 5mm, the taper is 0°, and the inner diameter of the two semicircular inner wall mold tubes is 120mm.

[0040] The inner surface roughness of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com