Automatic overturning bale breaker

An automatic flipping and unpacking machine technology, which is applied in the directions of packaging, transportation and packaging, and unsealing of objects, can solve the problems of debris, small slits, and material residues in packaging bags, so as to reduce labor intensity and improve work efficiency , the effect of reducing the likelihood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

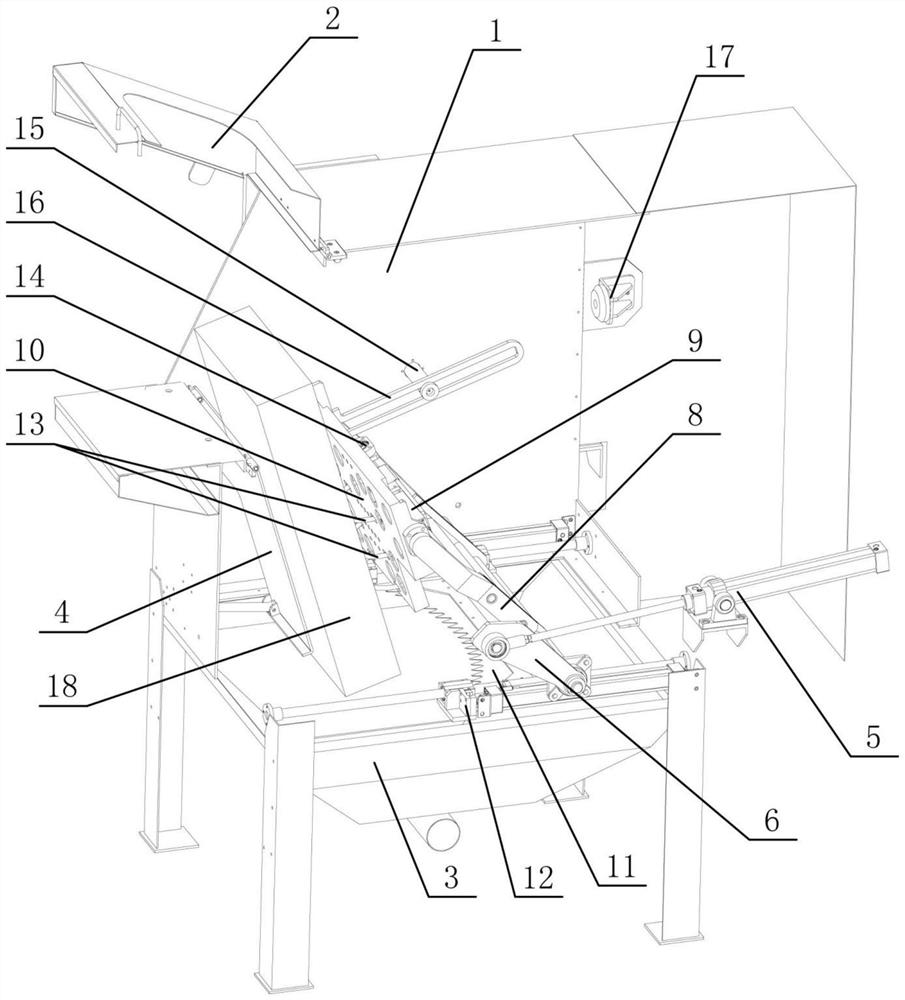

[0019] Embodiments of the present invention provide an automatic flip unpacking machine, such as Figure 1-2 As shown, it includes a material bin 1, a machine cover 2, a discharge bottom section 3, a material bracket 4, a rotating cylinder 5, a connecting rod 6, a main shaft 7, a main support 8, a turning cylinder 9, a material carrier 10, and a cutting knife 11. Cutting cylinder 12, hook 13, hook cylinder 14, guide column 15, guide frame 16, buffer 17. A material bracket 4 is fixed inside the silo 1 . The material bin 1 is provided with a machine cover 2 , and the machine cover 2 is located above the material bracket 4 . The material bin 1 is provided with a discharge bottom section 3 , and the discharge bottom section 3 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com