5G-based fan operation and maintenance system and method and electronic equipment

A technology for operation and maintenance systems and wind turbines, applied in mechanical equipment, services based on specific environments, wind power generation, etc., can solve problems such as high cost, large safety hazards, and poor real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A 5G-based wind turbine operation and maintenance system, including:

[0044] The data acquisition unit is used for real-time acquisition of vibration data, noise conditions and internal temperature and humidity conditions of the fan cabin and tower;

[0045] The edge computing unit interacts with the data acquisition unit to process the acquired data;

[0046] The cloud platform interacts with the edge computing unit and transmits the processed data to the external centralized control center;

[0047] The 5G signal coverage network is used to transmit the acquired data and the processed data.

Embodiment 2

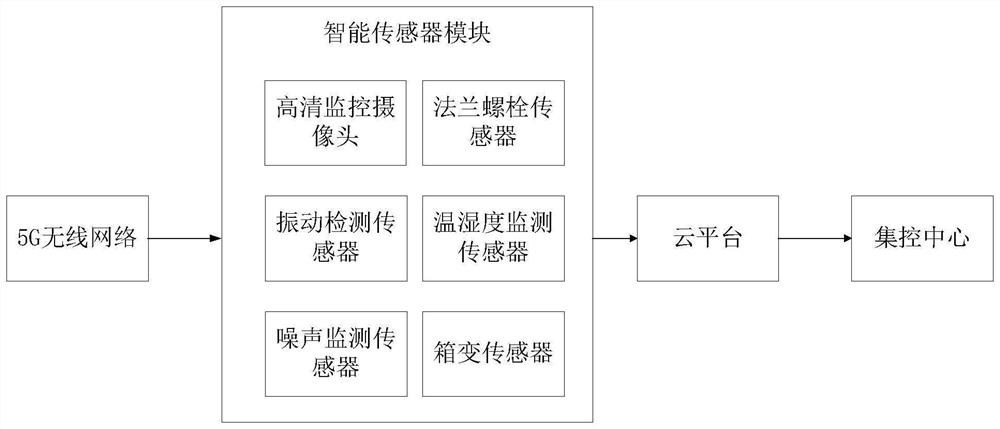

[0049] A 5G-based wind turbine operation and maintenance system, such as figure 2 shown, including:

[0050] The data acquisition unit is used for real-time acquisition of vibration data, noise conditions and internal temperature and humidity conditions of the fan cabin and tower;

[0051] The data acquisition unit includes a video monitoring module, a vibration detection module, a noise monitoring module and a temperature and humidity monitoring module;

[0052] The video monitoring module is used to obtain real-time video stream information inside and outside the wind turbine cabin and inside and outside the tower;

[0053] The vibration detection module is used to obtain the vibration degree of the bearing seat of the fan nacelle and the key parts of the casing;

[0054] The noise monitoring module is used to obtain the noise inside the fan cabin;

[0055] The temperature and humidity monitoring module is used to obtain the temperature and humidity data inside the fan c...

Embodiment 3

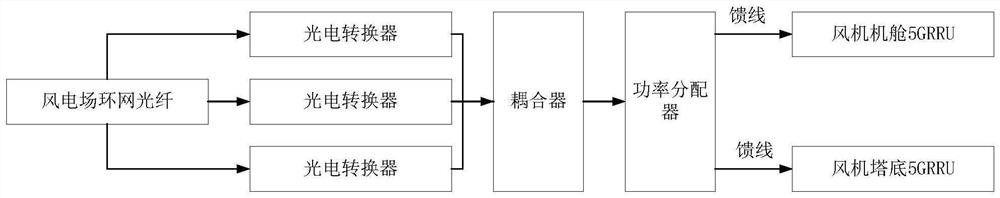

[0061] Such as figure 1 As shown, a 5G RRU remote variable frequency antenna system is deployed inside a single wind turbine, and a passive distribution system is adopted. In the specific device deployment, the optical fiber converter connects the end of the wind turbine ring network in the wind turbine, and converts the optical signal in the wind turbine ring network into an electrical signal; Power redistribution; through two feeders, one feeder is connected to the 5G RRU antenna at the bottom of the tower, and the other feeder is connected to the 5GRRU antenna in the cabin through the tower, thereby completing the 5G wireless signal coverage inside the entire wind turbine.

[0062] Deploy an intelligent operation and maintenance system on the cloud platform of the centralized control center, such as figure 2As shown, the system is composed of edge computing unit, data acquisition unit and cloud platform. The data acquisition unit is an intelligent sensor device, includin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com