Deep hole blasting pretreatment construction method for high-strength spherical weathering body in shield section

A construction method and deep hole blasting technology, applied in blasting and other directions, can solve the problems of difficulty in carrying out construction operations, increase the number of warehouse openings, and high construction requirements, and achieve the effects of reducing surrounding environmental risks, speeding up construction progress, and reducing construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

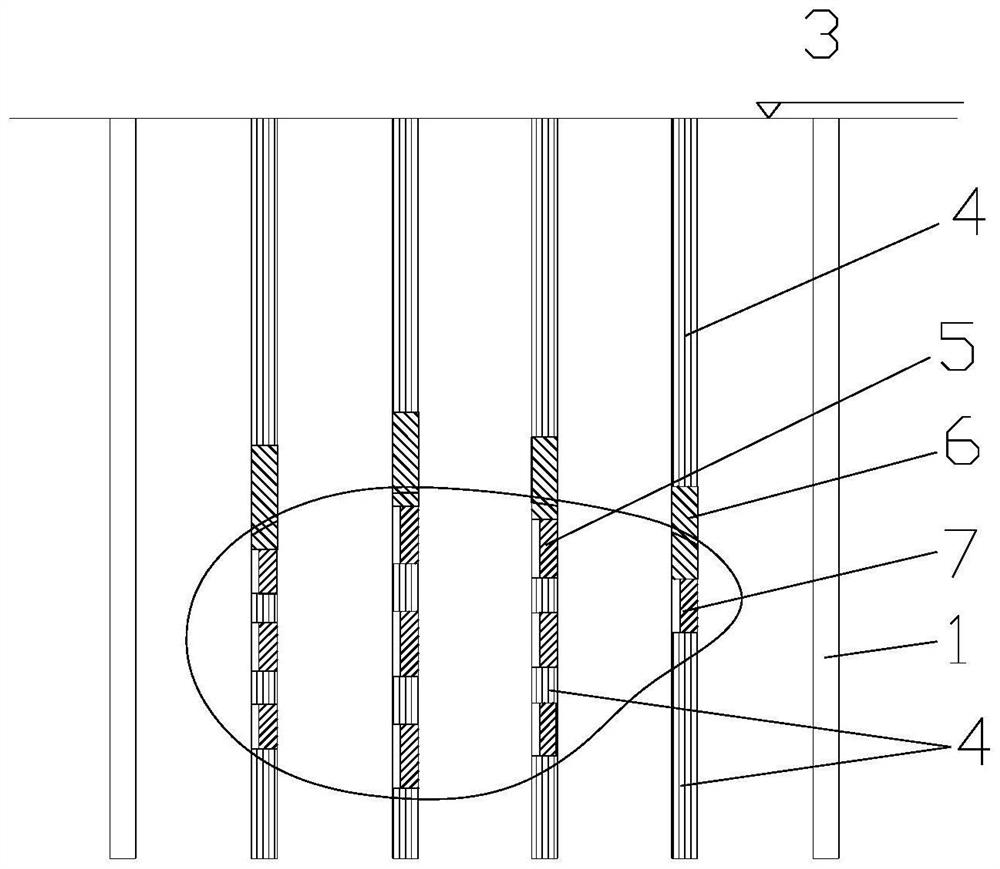

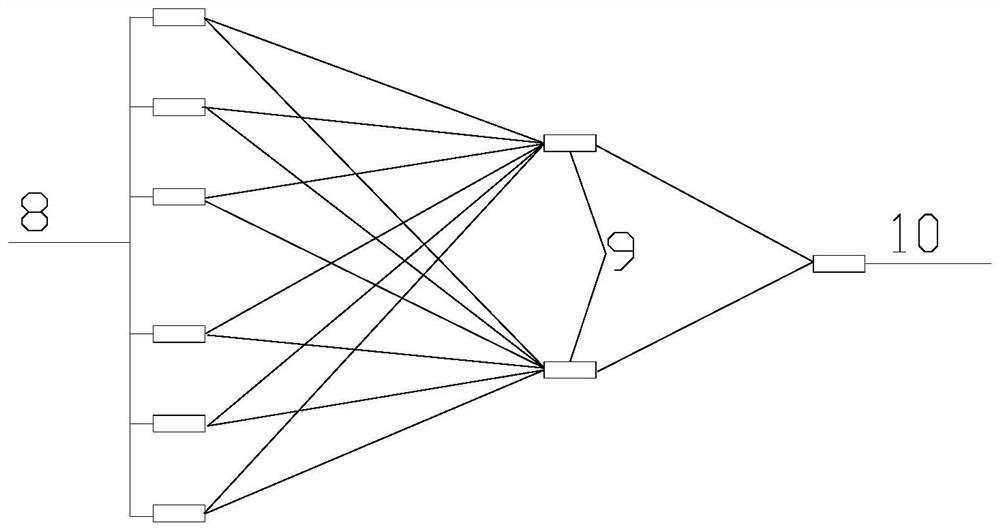

[0024] see Figure 1 ~ Figure 4 , a construction method for deep-hole blasting pretreatment of high-strength spherical weathered bodies in a shield section, using deep-hole weak loosening blasting, comprising the following steps:

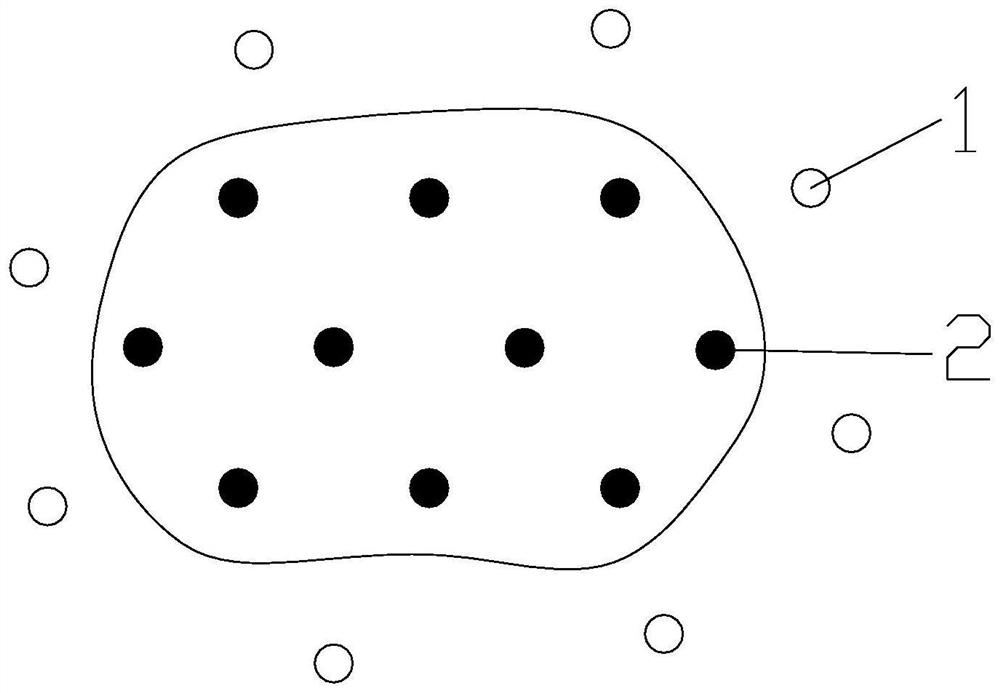

[0025] 1) Through geological supplementary survey, circle the plane range of the spherical weathered body within the tunnel range, and determine the depth range of the spherical weathered body to be treated. The specific method is as follows:

[0026] According to the geological survey report, carry out geological supplementary exploration in the shield section, spread out to the surrounding geological supplementary exploration centering on the geological exploration hole of the proven spherical weathered body, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com