Dry-type transformer coil winding equipment for frequency conversion and speed regulation

A dry-type transformer and variable frequency speed regulation technology, which is applied in the field of transformers, can solve the problems of low winding efficiency, inconvenient disassembly, and large space occupied by a single-pole winding roller, so as to improve the winding efficiency and reduce the space occupancy rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

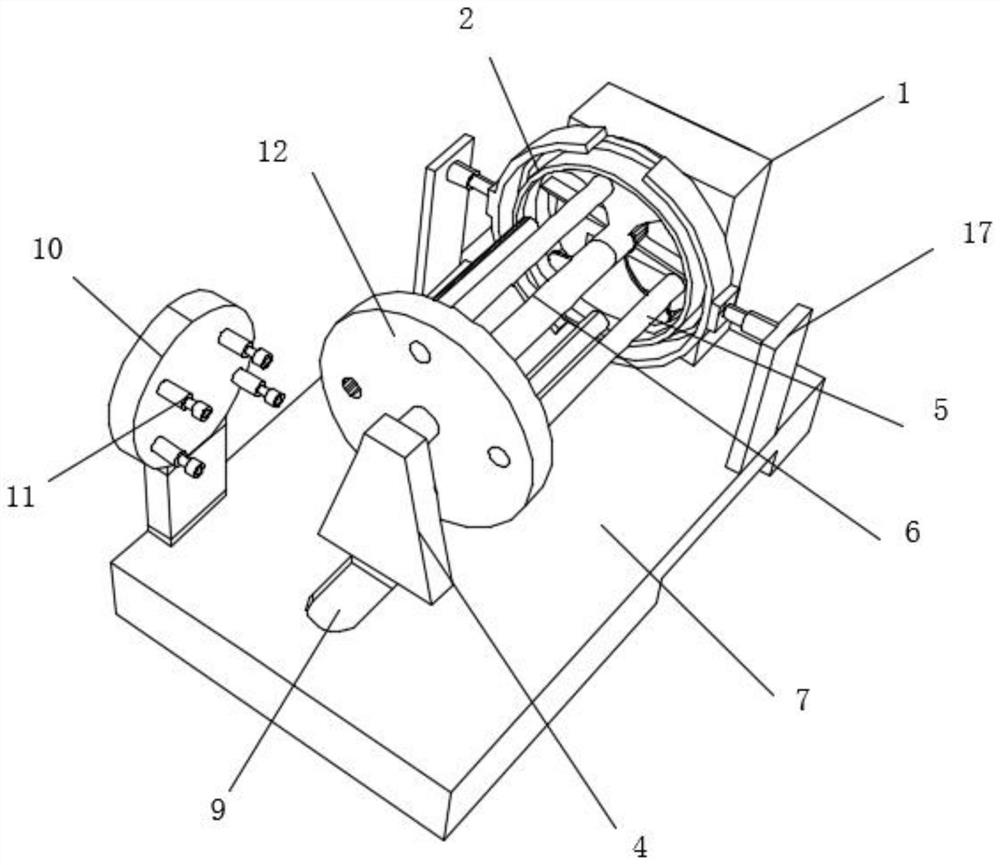

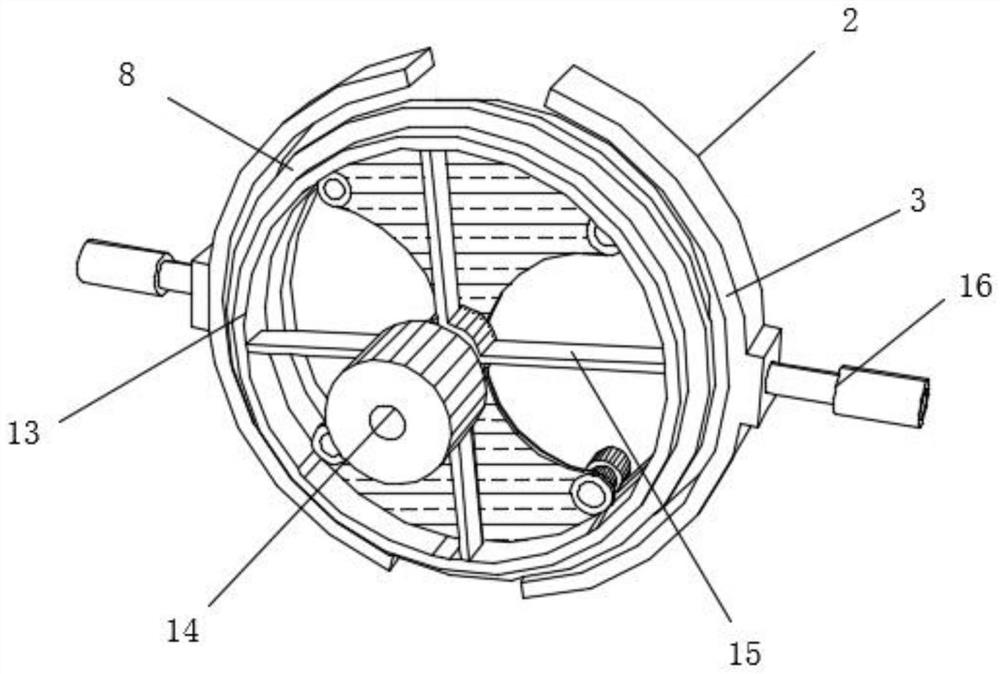

[0042] Such as Figure 1-7 As shown, the present invention provides a dry-type transformer coil winding equipment for frequency conversion and speed regulation, which includes a main device 1, a winding assembly 2 and a discharge assembly 4. The main device 1 is provided with a receiving workbench 7 for undertaking work. The upper surface of one side of the table 7 is provided with a winding assembly 2, and the upper surface of the other side of the receiving workbench 7 is provided with a discharge assembly 4. The inside of the winding assembly 2 is provided with a side protection assembly 3, and the side protection assembly 3 The inner wall of the built-in toothed disc 13 is movably connected with a built-in toothed disc 13, and the inner wall of one end of the built-in toothed disc 13 is fixedly connected with a side support rotating rod 15. One side of the side supporting rotating rod 15 is installed with a winding motor 14, and the other side is installed with an auxiliary...

Embodiment 2

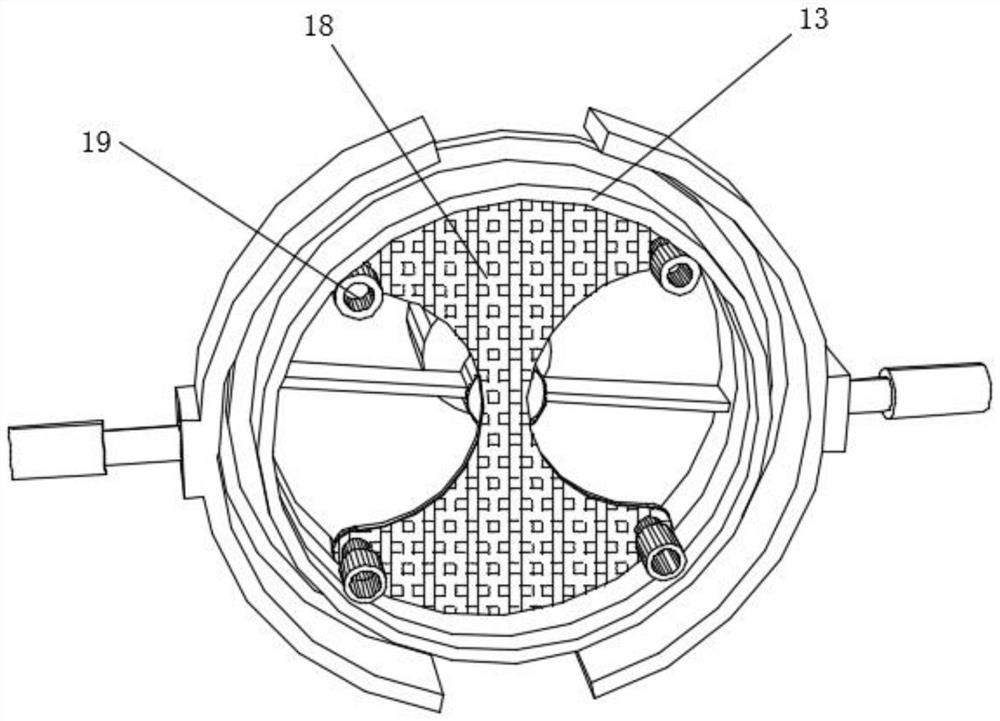

[0044] Such as Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the inner wall of the winding sleeve tooth 19 is provided with a built-in card slot 20, and the inner wall of the built-in card slot 20 is movably connected with an external card block 21 One side of the external clamping block 21 is fixedly connected to the winding roller 5, and the built-in card slot 20 provided on the inner wall of the winding sleeve tooth 19 can ensure that after the reinstallation of the unwound winding roller 5, the four groups of winding rollers 5 can Unified to prevent the winding roller 5 from being out of sync during the winding process, one end of the winding roller 5 is movably connected with an auxiliary winding turntable 12, and the center of one side of the auxiliary winding turntable 12 is movably connected with a transverse The support rod 6, the inside of the side position protection assembly 3 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com