Method for producing photovoltaic cell

A technology of photovoltaic cells and electrodes, applied in the direction of photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc., which can solve problems such as incomplete satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

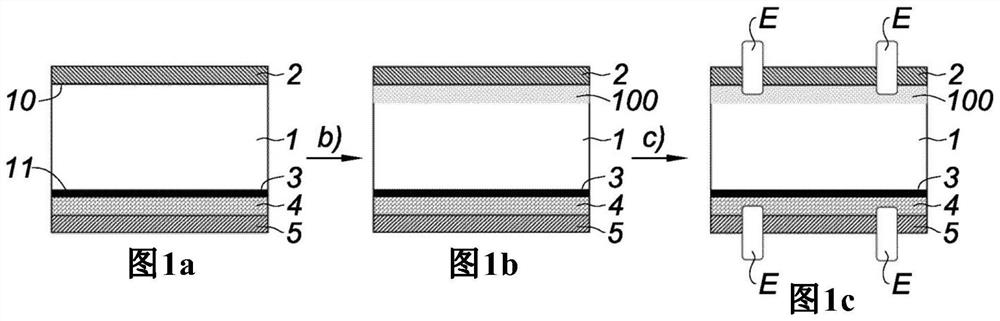

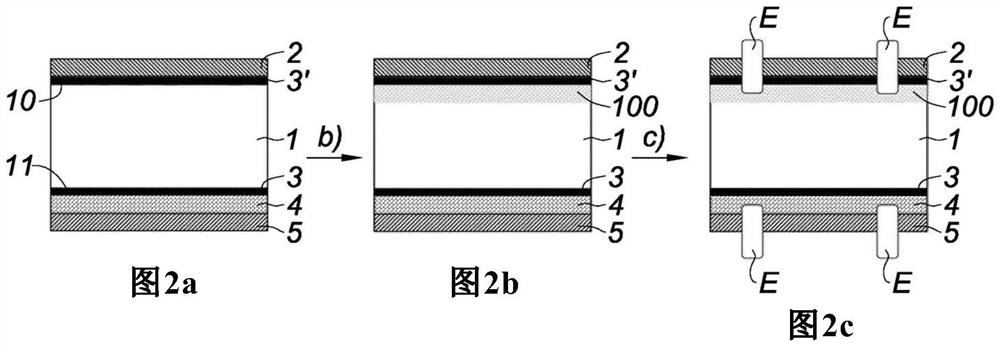

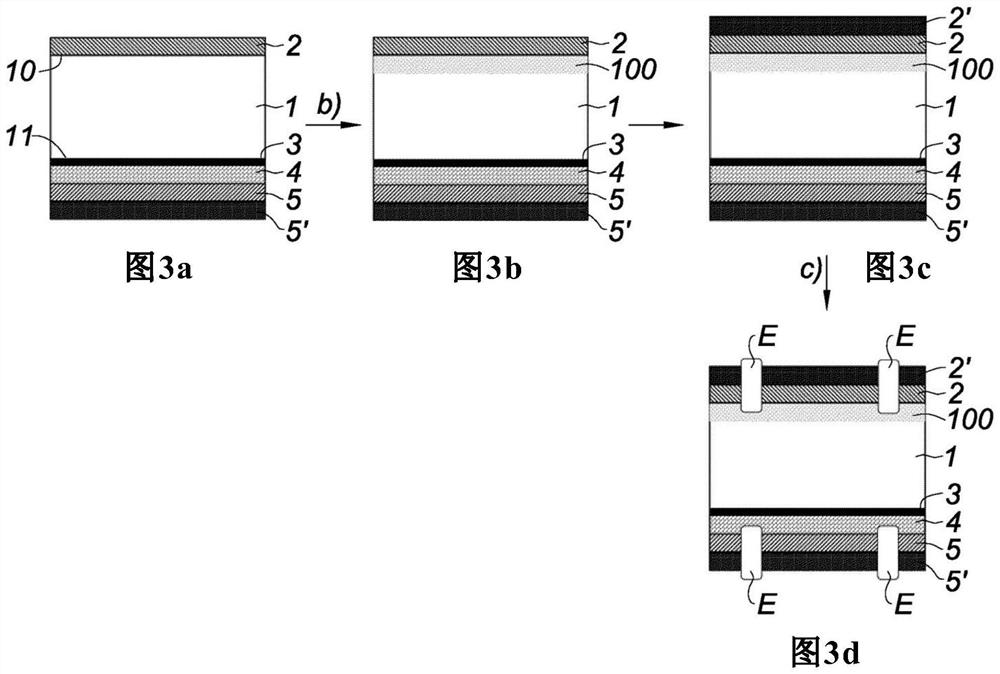

[0081] For the sake of simplicity, elements that are the same or perform the same function have been denoted by the same reference numerals in the various embodiments.

[0082] A subject of the invention is a method for manufacturing a photovoltaic cell comprising the steps of:

[0083] a) setting a structure, said structure comprising:

[0084] - a substrate 1 based on crystalline silicon having a first surface 10 and an opposite second surface 11;

[0085] - a first dielectric layer 2 comprising boron atoms and formed on the first surface 10 of the substrate 1;

[0086] - a tunnel oxide film 3 formed on the second surface 11 of the substrate 1;

[0087] - a polysilicon layer 4 formed on the tunnel oxide film 3;

[0088] - a second dielectric layer 5 comprising phosphorus and / or arsenic atoms and formed on the polysilicon layer 4;

[0089] b) apply heat treatment to the structure in order to:

[0090] - allowing boron atoms to diffuse from the first dielectric layer 2 be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com