Conch-imitating bioactive scaffold as well as preparation method and application thereof

A bioactive, conch technology, applied in bone implants and other directions, can solve the problems of low cell load rate, limited osteogenic effect, and low function, and achieve the effect of improving biological activity and enhancing cell delivery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Use SolidWorks software to design the model of the bionic stent, design a cylindrical imitation conch bioactive stent with a diameter of 13mm and a height of 15mm, the number of through holes in the peripheral wall is 12, the diameter is 1.2mm, and the pitch of the helical nodes is 1.6 , 2.0, 2.4mm three kinds. The designed bionic bracket model data is output as an STL format file, and it is imported into the processing software of the DLP type light-curing 3D printer (purchased from Beijing Shiwei Technology Co., Ltd., the model is AUTOCERA-M) to set parameters and slices. Export it as a 3D printing file format TDP that can be recognized by the printer, and then import the TDP file into a DLP-type stereolithography 3D printer.

[0059] β-TCP powder (purchased from Kunshan Huaqiao Technology New Material Co., Ltd.) 40g, and 17.5g photosensitive resin (epoxy acrylic resin, purchased from Jinhua Marriott Parts Co., Ltd.), 10g 1,6-hexanediol diacrylic acid (HDDA , purchas...

Embodiment 2

[0063] Use SolidWorks software to design the model of the bionic stent, design the cylindrical imitation conch bioactive stent with a diameter of 13 mm and a height of 15 and 30 mm, the pitch of the helical section is 2.4 mm, and the diameter of the through hole on the peripheral wall is 1.2 mm. The number of holes is 8, 12, and 16; when the number of through holes on the peripheral wall is 12, the diameters are 1.0, 1.2, and 1.5mm. One of the through holes in the peripheral wall of the above-mentioned scaffold is replaced by a hole with a diameter of 1.5 mm to communicate with the helical cavity in the middle of the scaffold as a cell addition hole of the scaffold. The designed bionic bracket model data is output as an STL format file, and it is imported into the processing software that comes with the DLP type light-curing 3D printer to set parameters and slices, and exported to the 3D printing file format TDP that the printer can recognize, and then the TDP file Imported in...

Embodiment 3

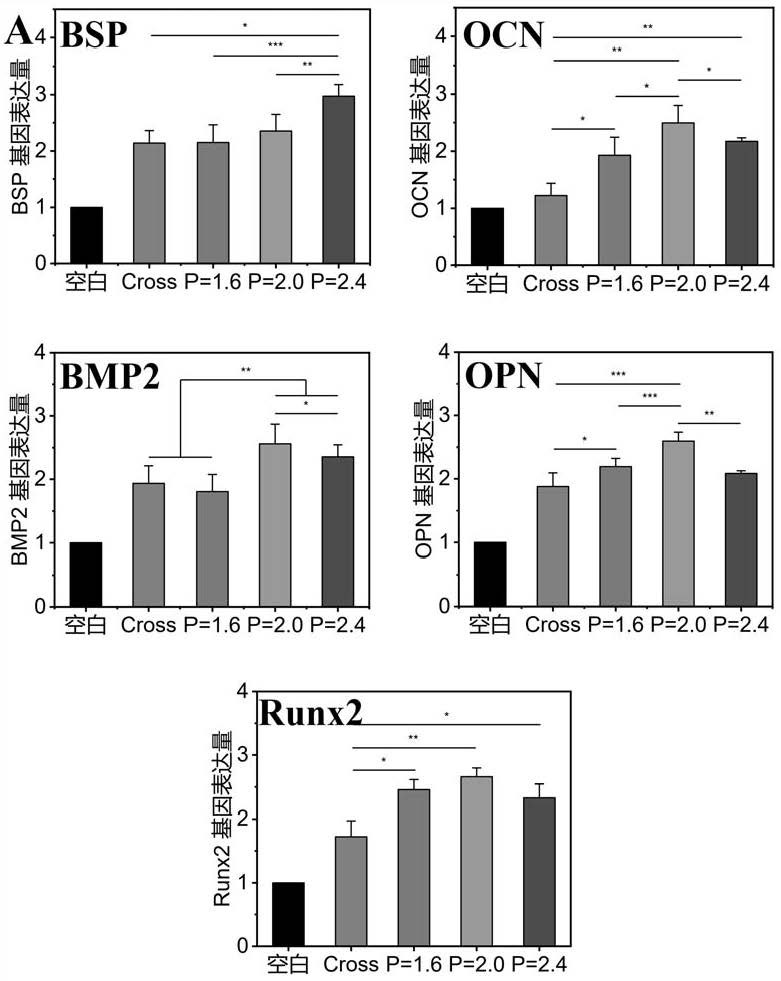

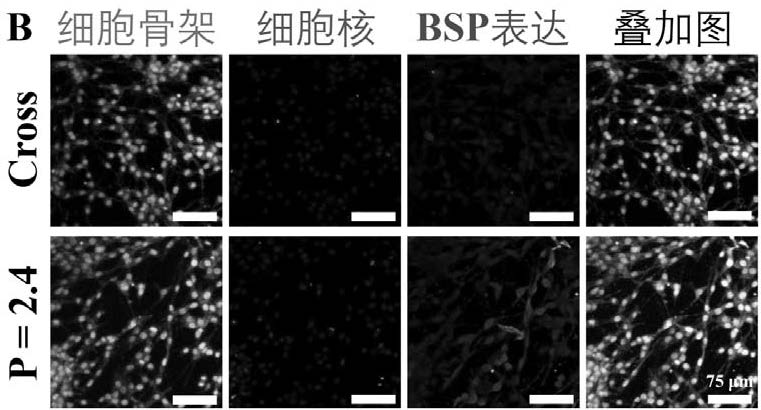

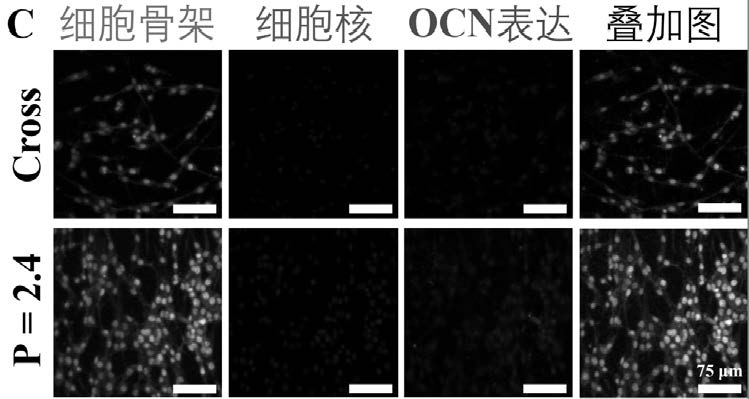

[0068] Use the SolidWorks software to design the model of the bionic stent, design a cylindrical imitation conch bioactive stent with a diameter of 13mm, a height of 5mm, a diameter of 13mm, and a height of 15mm and a traditional cross-pillar stent, and the number of through holes in the peripheral wall is 12 , with a diameter of 1.2mm, and the pitches of the helical segments are 1.6, 2.0, and 2.4mm respectively. One of the through holes in the peripheral wall of the above-mentioned scaffold is replaced by a hole with a diameter of 1.5 mm to communicate with the helical cavity in the middle of the scaffold as a cell addition hole of the scaffold. The designed bionic bracket model data is output as an STL format file, and it is imported into the processing software that comes with the DLP type light-curing 3D printer to set parameters and slices, and exported to the 3D printing file format TDP that the printer can recognize, and then the TDP file Imported into DLP type light cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com