Forestry impurity stirring and crushing device

A crushing device and sundry technology, which is applied in the field of forestry sundry mixing and crushing devices, can solve the problems of inability to ensure the uniformity of the sundries crushed material, damage to parts of the stirring and crushing device, etc., so as to ensure the uniformity of crushing, high crushing efficiency, The effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

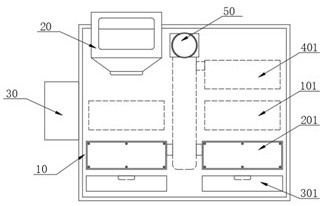

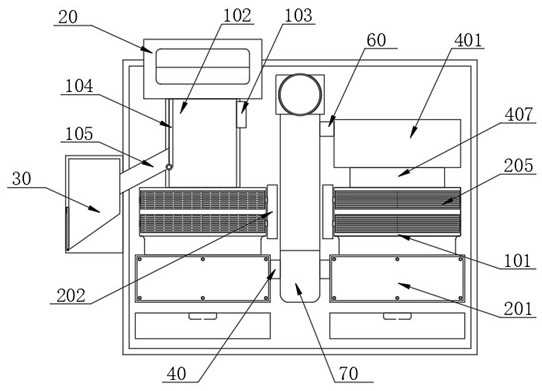

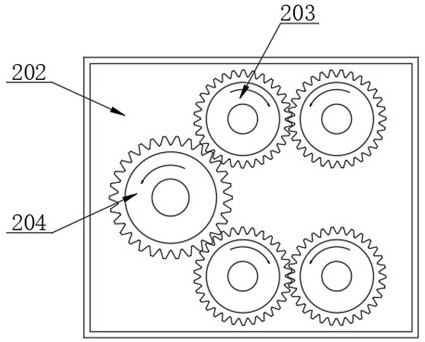

[0040] see Figure 1-6 Shown, a kind of forestry is used the sundry mixing crushing device, comprises cabinet 10 and feed hopper 20, and feed hopper 20 is arranged on the top of cabinet 10 front, and the left side of cabinet 10 is provided with material storage box 30, and the left side of cabinet 10 A first crushing mechanism and a second crushing mechanism are arranged symmetrically in the interior, and both the first crushing mechanism and the second crushing mechanism include a crushing box 101, a screening box 201 and a collection box 301, and the inside of the cabinet 10 is located in the first crushing mechanism and the A pneumatic feeding pipe 70 is arranged between the second crushing mechanism, and a weighing box 401 is arranged inside the cabinet 10 and above the second crushing mechanism;

[0041] The inside of the cabinet 10 is provided with a drop tube 102, and the top of the drop tube 102 communicates with the bottom end of the feed hopper 20, the right side of ...

Embodiment 2

[0051] see Figure 7 As shown, the cabinet 10 in the present invention is provided with a control panel, and the inside of the control panel is provided with a data acquisition module, a data processing module, a processor, an alarm module, a crushing control module and a data recording module;

[0052] The data acquisition module will collect the total weight of sundries, the crushed material weight inside the collecting box 301 in the first crushing mechanism, the crushed material weight inside the weighing box 401, and the crushed material weight data inside the collecting box 301 in the second crushing mechanism. Transmit to the data processing module, wherein be positioned at two collecting boxes 301 insides and be positioned at the weighing sensor 402 of weighing box 401 insides all be provided with weighing sensor, utilize weighing sensor to gather and obtain the inside of collecting box 301 in the first pulverizing mechanism The crushed material weight, the crushed mat...

Embodiment 3

[0062] see Figure 1-7 As shown, the present invention also discloses a working method of a forestry debris stirring and crushing device, which specifically includes the following steps:

[0063]Step S1, weigh the total weight of the sundries sent into the cabinet 10 in advance, send the forestry sundries into the drop pipe 102 through the feed hopper 20, energize the electromagnet 103, and use the electromagnet 103 to remove the forestry sundries. The metal sundries in the tank are adsorbed, and the remaining sundries enter the crushing box 101 of the first crushing mechanism through the drop pipe 102. After the feeding process of the sundries is completed, the bottom end of the movable plate 302 is controlled to turn over and move One side of the plate 302 is in contact with the right side of the inner wall of the blanking tube 102, and the electromagnet 103 is powered off, and the metal debris absorbed by the electromagnet 103 enters the material storage box 30 along the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com