Flange sealant breakpoint-free smearing process applied to offshore wind turbine installation

A technology for flange sealing and offshore fans, which is applied in coatings, devices for coating liquid on the surface, foam dispersion/prevention, etc., can solve the problem of reducing the protection degree of sealants to flanges, affecting the waterproof and anti-corrosion of sealants, and affecting Effective and continuous use of the rack to achieve the effect of improving the waterproof and anti-corrosion effect, reducing the probability of cracking, and improving the efficiency of air bubble release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

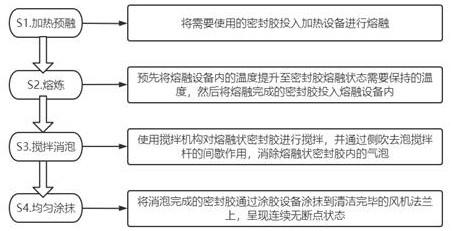

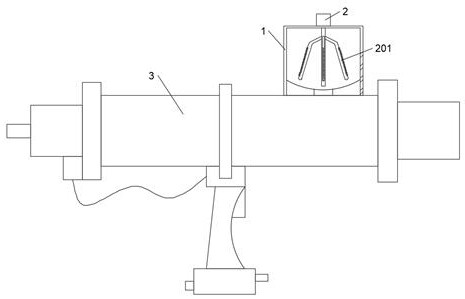

[0051] see Figure 1-10 , a non-breakpoint application process of flange sealant applied to the installation of offshore wind turbines, including the following steps:

[0052] S1. Heating and pre-melting: Put the sealant to be used into the heating equipment for melting;

[0053] S2. Melting: raise the temperature in the melting device 1 to the temperature that needs to be maintained in the molten state of the sealant in advance, and then put the melted sealant into the melting device 1;

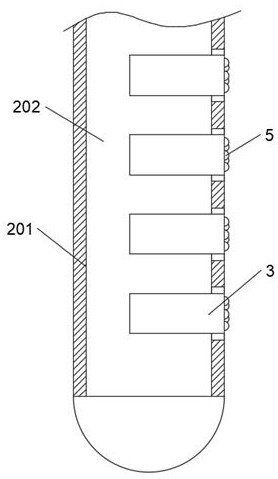

[0054] S3. Stirring and defoaming: use the stirring mechanism 2 to stir the molten sealant, and eliminate the air bubbles in the molten sealant through the intermittent action of the side blowing defoaming stirring rod 201;

[0055] S4. Apply evenly: Apply the defoamed sealant to the cleaned fan flange through the glue application device 3, showing a continuous state without breakpoints; add side blowing defoaming stirring rod 201 during melting and stirring to assist The elimination of ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com