Laser processing method, laser processing equipment and storage medium

A laser processing method and laser technology, applied in laser welding equipment, metal processing equipment, metal processing, etc., can solve problems such as product deformation, inaccurate processing, and inaccurate processing, and achieve high-precision laser processing and improve accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

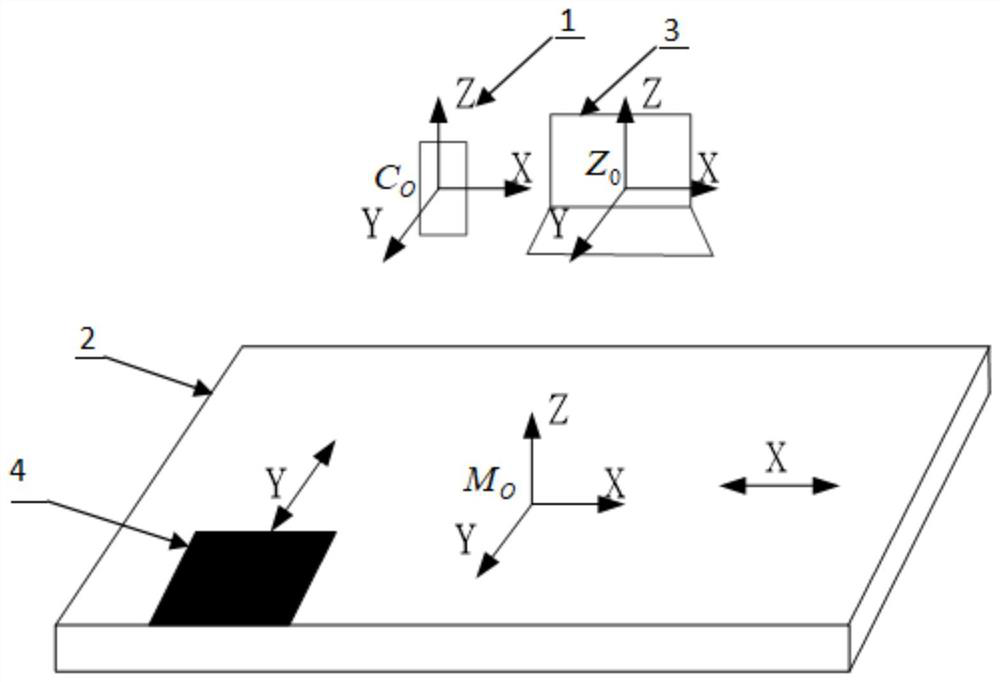

[0049] This embodiment discloses a laser processing method, which is applied to laser processing equipment, such as a laser cutting machine. figure 1 It is a schematic diagram of a laser processing device in an embodiment of the present invention, such as figure 1 As shown, the laser processing device includes a processing platform 2 , a camera 1 and a vibrating mirror 3 . The processing platform 2 is used to place the product 6, and the processing platform 2 can be an XY platform, that is, a two-dimensional module that can move along the X direction and the Y direction. Camera 1 can be a CCD camera. Both camera 1 and galvanometer 3 are located above the XY platform, and camera 1 is on the left side of galvanometer 3 .

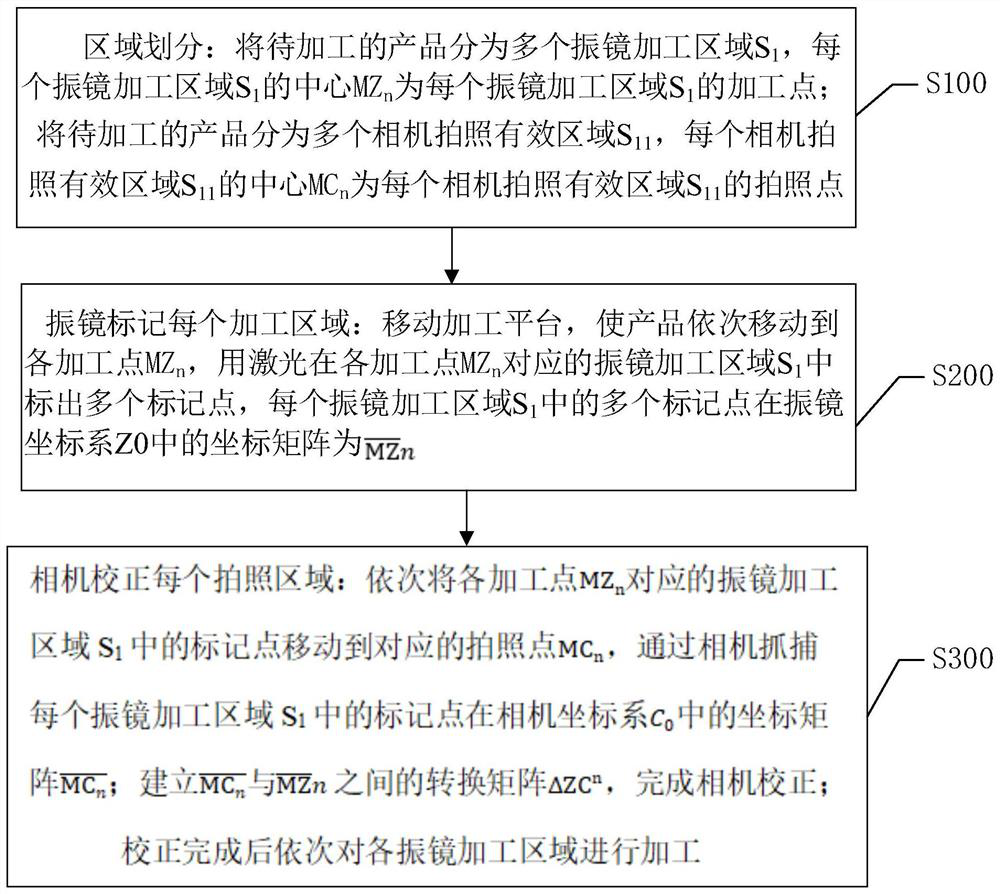

[0050] Based on the above laser processing device, the present invention proposes a laser processing method. The laser processing method can include galvanometer correction and multi-region camera correction. After the correction is completed, the product c...

Embodiment 2

[0087] Embodiment 2 of the present invention is also to provide a laser processing device, which may include but not limited to: one or more processors, and memory.

[0088] As a computer-readable storage medium, the memory can be used to store software programs, computer-executable programs and modules, such as program instructions corresponding to the laser processing method in the embodiment of the present invention. The processor executes various functional applications and data processing of the laser processing equipment by running the software programs, instructions and modules stored in the memory, that is, realizes the above-mentioned laser processing method.

[0089] The memory may mainly include a program storage area and a data storage area, wherein the program storage area may store an operating system and an application program required by at least one function; the data storage area may store data created according to the use of the terminal, and the like. In ad...

Embodiment 3

[0091] Embodiment 3 of the present invention also provides a computer-readable storage medium on which a computer program is stored. When the program is executed by a processor, a laser processing method is implemented. The laser processing method includes the following steps:

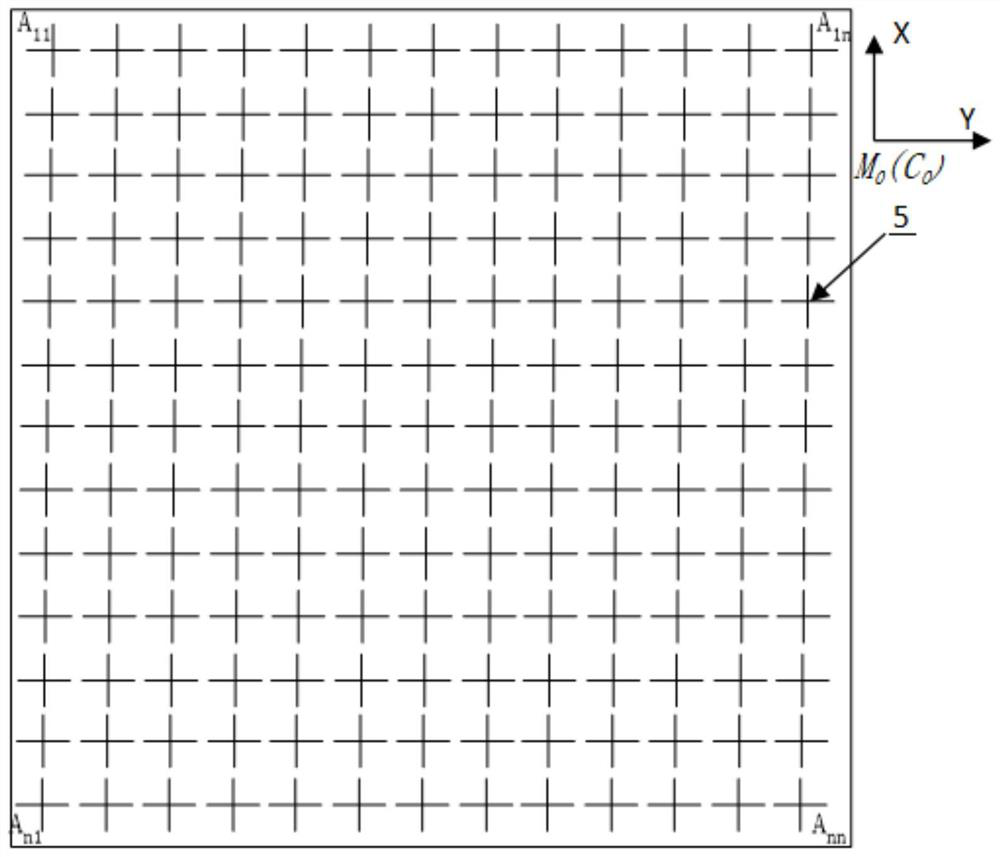

[0092] S10. Area division: Divide the product to be processed into multiple galvanometer processing areas S 1 , each galvo processing area S 1 Center of MZ n Area S machined for each galvo 1 processing point;

[0093] Divide the product to be processed into multiple camera effective areas S 11 , the effective area S of each camera 11 Center MC n Take pictures of the effective area S for each camera 11 photo spots;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com