Novel laser beam repairing machine workbench

A laser beam and workbench technology, applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as chip yield reduction, integrated circuit opening, short circuit abnormality, etc., and achieve simple and convenient operation, clear display images, The effect of improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

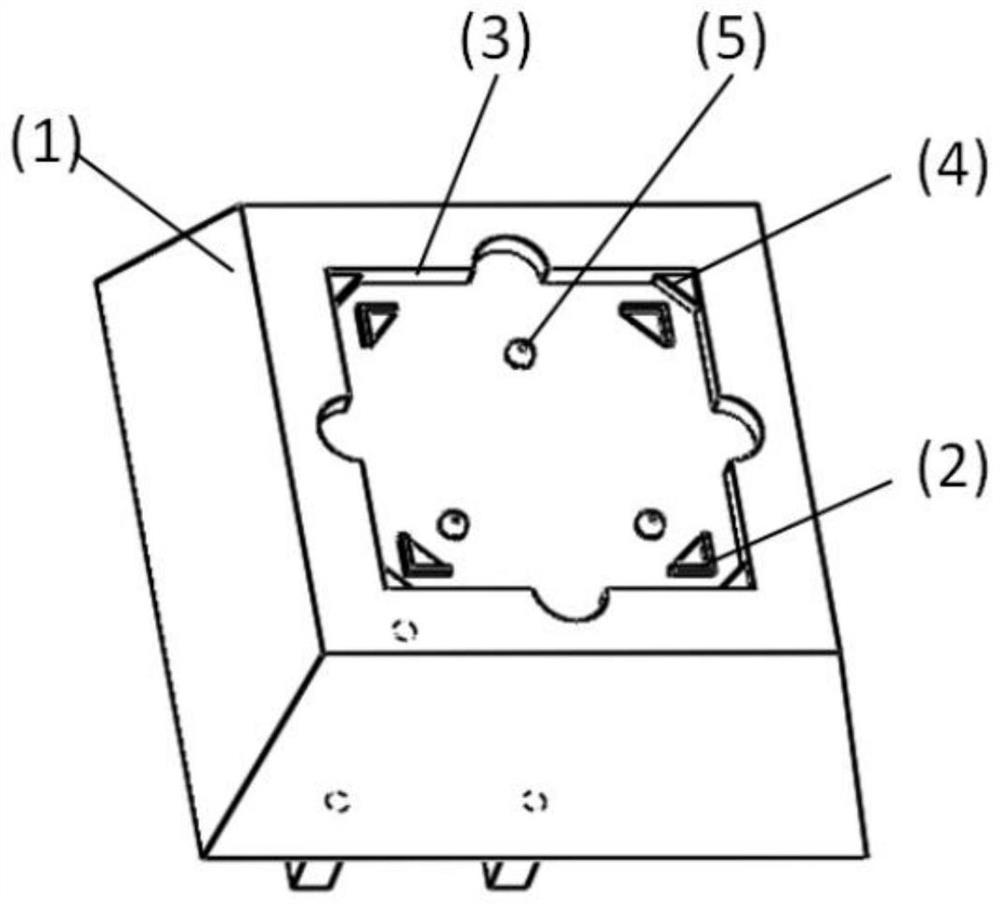

[0014] Such as figure 1 As shown, the specific embodiment adopts the following technical solutions: a novel laser beam repair machine workbench, including a placement platform 1, the top of the placement platform 1 is provided with a placement groove 3, and the four corners of the placement groove 3 are fixedly connected with triangular support plates 4. Four L-shaped limit bars 2 are fixedly connected to the bottom of the placement slot 3;

[0015] A 5-inch reticle that needs to be repaired can be placed between the L-shaped limit bars 2, and a 6-inch reticle that needs to be repaired can be placed on the triangular support plate 4 inside the placement slot 3 to achieve the purpose of flexible repair of the workbench. When taking out and replacing the mask plate, the mask plate can be grasped from the hollow grooves around it, which is convenient for operation and avoids the need to pry to take the material.

Embodiment 2

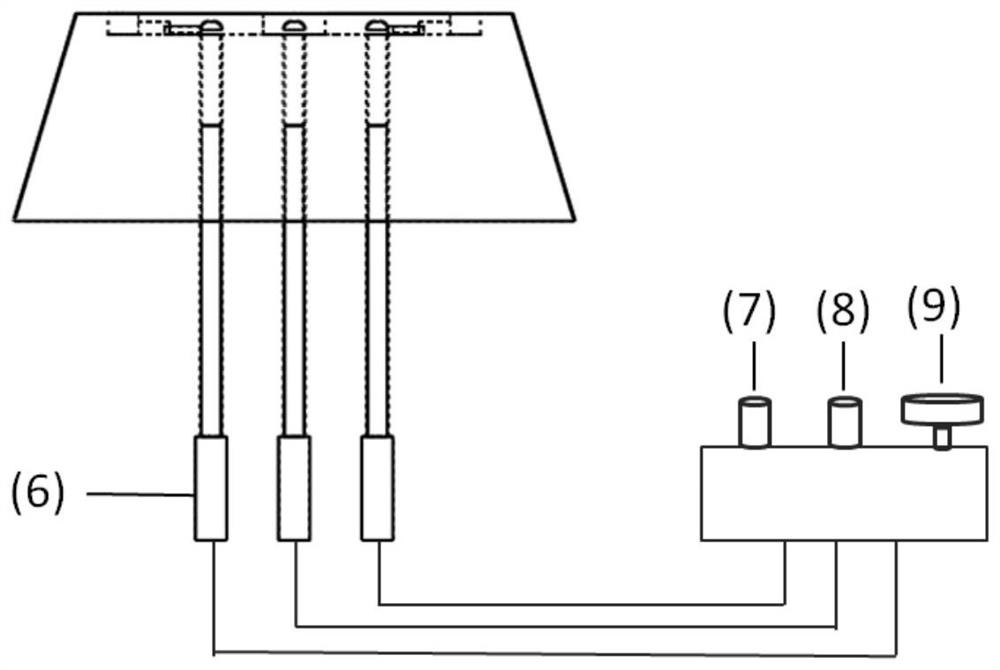

[0017] Such as figure 2 As shown, this embodiment adopts the following technical solutions:

[0018] The bottom of the placement slot 3 is located between the four L-shaped limit bars 2, and three support thimbles 5 are provided. The outside of the placement slot 3 is hollowed out, and the bottom of the placement platform 1 is provided with three servo motors 6. The output end of the servo motor 6 is connected to the support The thimble 5 is threaded, and the outside of the platform 1 is provided with a controller. The controller is provided with a No. 1 toggle switch 7, a No. 2 toggle switch 8 and a fine-tuning knob 9. The controller is electrically connected with three servo motors 6 .

[0019] The servo motor 6 at the bottom of the placement platform 1 is controlled by the controller, and the three supporting thimbles 5 are simultaneously driven to rise to the initial height set by the No. 1 toggle switch 7 at the same speed, and the reticle of the repair product is comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com