Steel bearing ring and preparation method thereof

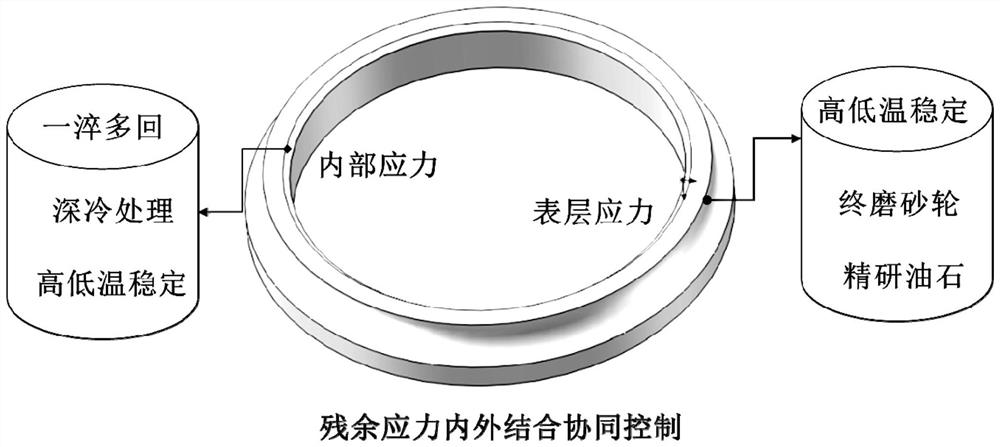

A bearing ring and steel technology, applied in the field of steel bearing rings and their preparation, can solve problems such as time-consuming, inability to achieve effective connection, uneven deformation, etc., to ensure service safety, improve precision retention and The effect of resistance to deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

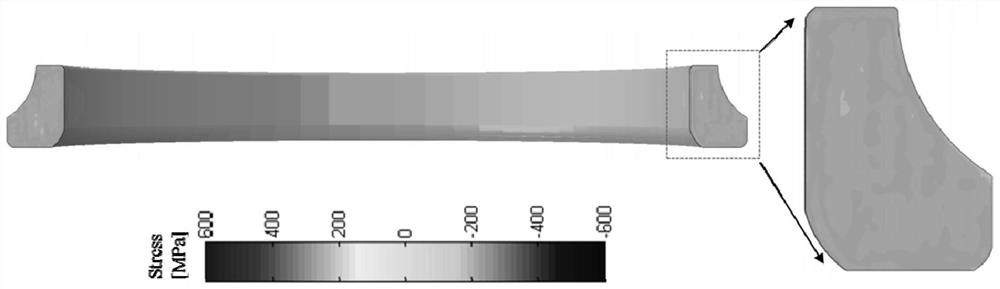

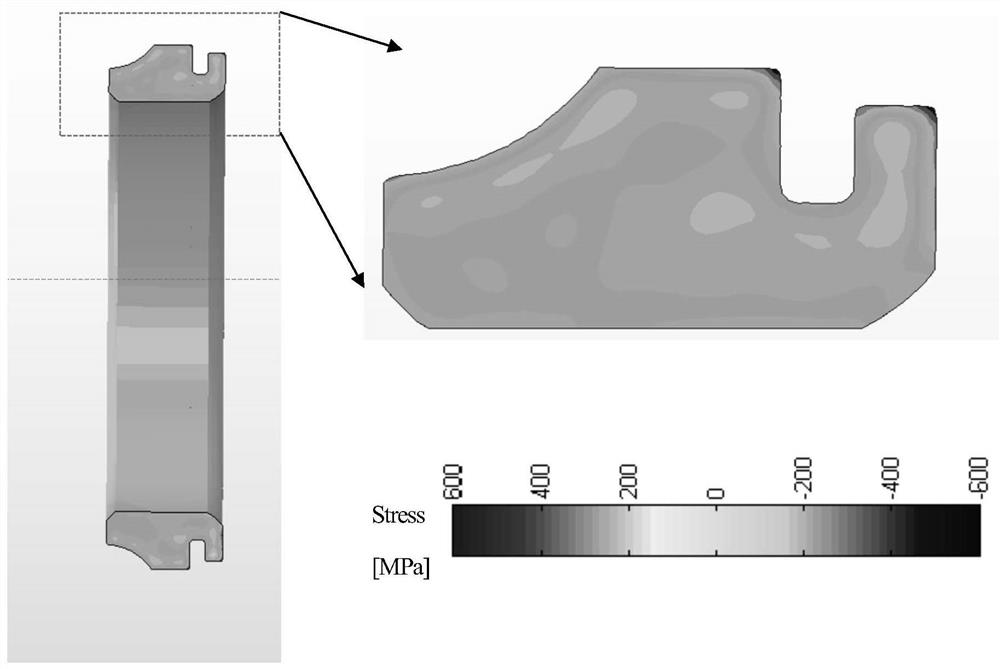

[0051] M50 steel lathe is used to obtain the semi-inner ring blank of the No. 1 bearing, and the blank is quenched at a temperature of 1110 °C, and the holding time is 30 minutes. After 15 minutes, it is cooled to below 100 °C; after quenching, deep cooling is carried out. The cold temperature is -68°C, and the duration is 1h; the deep-cooled blank is treated with three tempering processes. After tempering, carry out cryogenic cooling, the cryogenic temperature is -68°C, and the duration is 1h. After three times of tempering, the volume content of retained austenite is 0.9%; The tempering stabilization treatment was carried out respectively, among which the tempering stabilization temperature after rough grinding was 550°C and the time was 1h, and the tempering stabilization temperature after fine grinding was 140°C and the time was 4h; finally, the channel final grinding and fine grinding were carried out. The feed speed of the final grinding wheel is 0.002mm / s, the type of g...

Embodiment 2

[0053] M50 steel lathe is used to process the blank of the No. 2 bearing semi-inner ring, and the blank is quenched. The quenching temperature is 1075 ° C, the holding time is 40 minutes, and it is cooled to below 100 ° C after 13 minutes; the cryogenic temperature after quenching is -75 ℃, the duration is 2.5h; three tempering processes are used to treat the cryogenic blank. The temperature and time of the three temperings are the same. The post-cryogenic temperature is -75°C, the duration is 2.5h, and the volume content of retained austenite is 0.8% after three times of tempering; rough grinding and fine grinding are carried out on the obtained rough, wherein, the rough grinding and fine grinding are respectively tempered Fire stabilization treatment, in which the tempering stabilization temperature is 525 ° C for 2.5 hours after rough grinding, and the tempering stabilization temperature is 250 ° C for 4 hours after fine grinding; finally, the channel final grinding and fine...

Embodiment 3

[0055] The semi-inner ring blank of the No. 3 bearing was processed by M50 steel lathe, and the blank was quenched. The quenching temperature was 1110°C, and the holding time was 35min. After 14min, it was cooled to below 100°C; after quenching, the cryogenic temperature was - 70°C, the duration is 70min; three tempering processes are used to treat the cryogenic blank, and the temperature and time of the three temperings are the same. The cryogenic temperature is -70°C, the duration is 70min, and the volume content of retained austenite is 1.4% after three times of tempering; rough grinding and fine grinding are carried out on the obtained blank, among which, tempering is carried out after the rough grinding and fine grinding to stabilize After rough grinding, the stable tempering temperature is 520°C and the time is 2.5h; after fine grinding, the tempering temperature is 135°C and the time is 4h; finally, the channel final grinding and fine grinding are carried out, and the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com