Cable traction device with traction cable adjusting function for electric power engineering

A technology for electric power engineering and cable traction. It is used in transportation and packaging, transportation of filamentous materials, and thin material handling. It can solve problems such as slippage, inability to change the traction direction, and poor cable clamping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

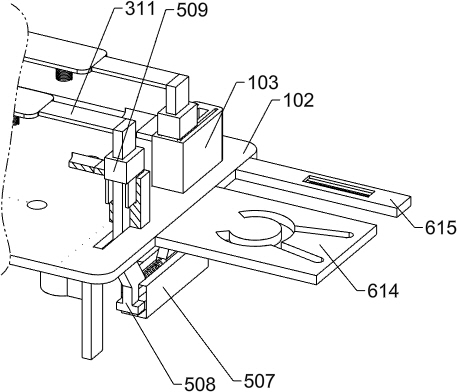

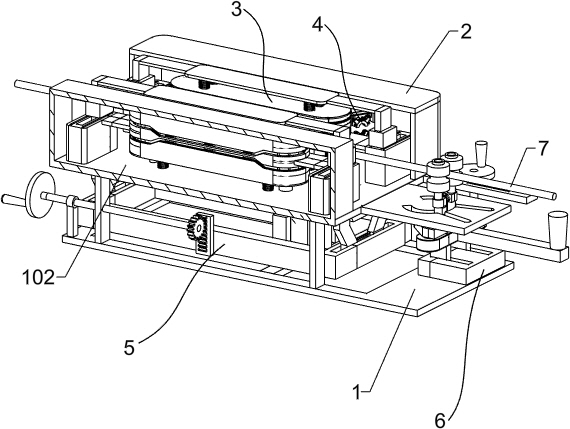

[0034] A cable pulling device with a pulling cable adjustment function for electric power engineering, such as figure 1 with figure 2 As shown, it includes a lower support plate 1, a support rod 101, an upper support plate 102, a first limit block 103, a protective shell 2, a transmission limit mechanism 3, a limit clamp mechanism 4, an auxiliary wire taking mechanism 5 and The cable guide mechanism 6, the lower support plate 1 is placed on the ground, two support rods 101 are arranged in two groups, and the two support rods 101 in one group are respectively fixedly connected to the left and right parts of the upper surface of the lower support plate 1, Two groups of support rods 101 are arranged symmetrically front and back on the upper surface of the lower support plate 1 respectively. Four first limit blocks 103 are evenly arranged on the left and right, and the lower ends of the four first limit blocks 103 are fixedly connected to the upper surface of the upper support p...

Embodiment 2

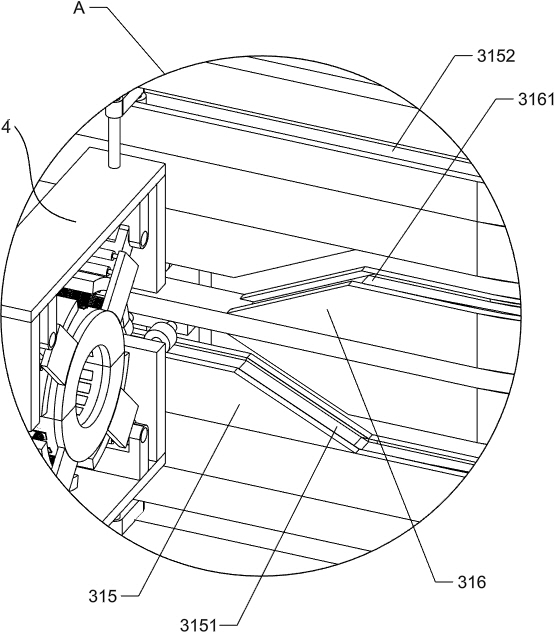

[0037] On the basis of Example 1, such as Figure 3-Figure 5 As shown, the transmission limit mechanism 3 includes a servo motor 301, a first gear 302, a second gear 303, a third gear 304, a first rotating shaft 305, a fixed rod 306, a pulley 307, a conveyor belt 308, and a second limit block 309, the third limit block 310 and the limit assembly, the lower end of the servo motor 301 is fixed on the upper surface of the lower support plate 1, the output shaft end of the servo motor 301 is fixed with the first gear 302, and the first rotating shaft 305 is connected to the upper On the right side of the support plate 102, the lower end of the first rotating shaft 305 is fixedly connected with the second gear 303 and the third gear 304. The front and rear sides of the first gear 302 mesh with the second gear 303 and the third gear 304 respectively. There are two fixed rods 306 symmetrically fixed on the front and rear sides, two first rotating shafts 305 and the upper parts of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com