Integrated deionizing device

A deionization and integrated technology, applied in the direction of ion exchange water/sewage treatment, etc., can solve the problems of extremely high installation space requirements for deionizers, loss of fuel cell coolant, and unfavorable OEM integration, so as to reduce design costs. , The effect of solving the outflow of coolant and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

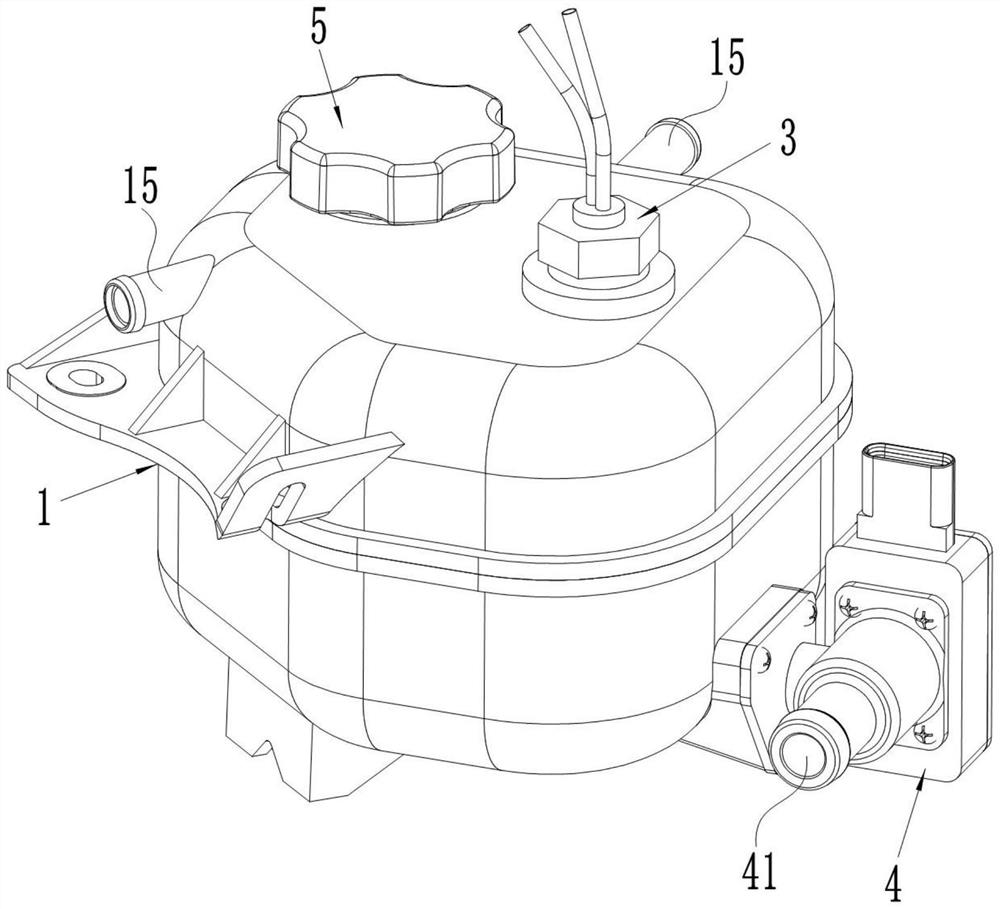

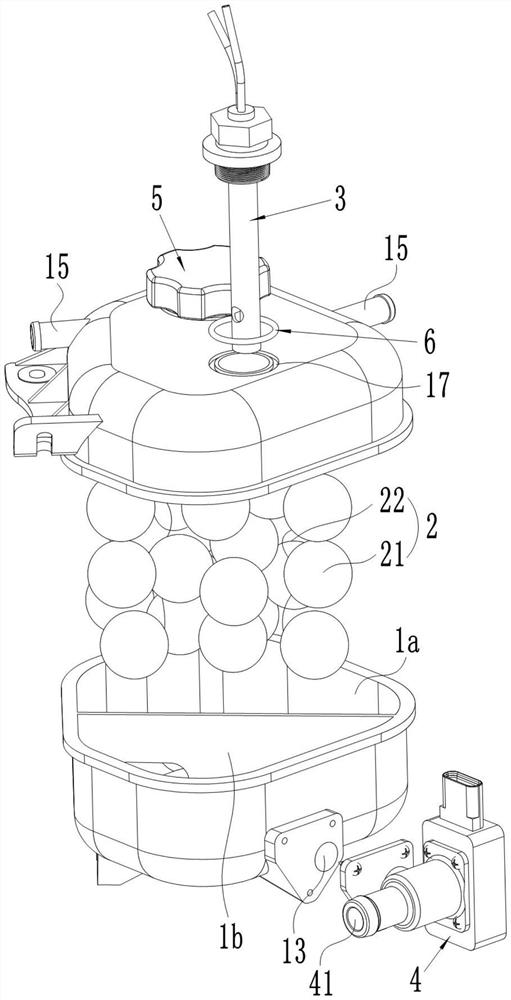

[0040] Such as figure 1 and figure 2 As shown, an integrated deionization device mainly includes an expansion kettle 1, a filter element assembly 2, a conductivity tester 3 and a control valve 4. In this embodiment, the filter element assembly 2 is installed in the expansion kettle 1, and the conductivity The rate tester 3 and the control valve 4 are also integrated on the expansion kettle 1, so that the structure of the whole deionization device is more compact and the installation space is reduced.

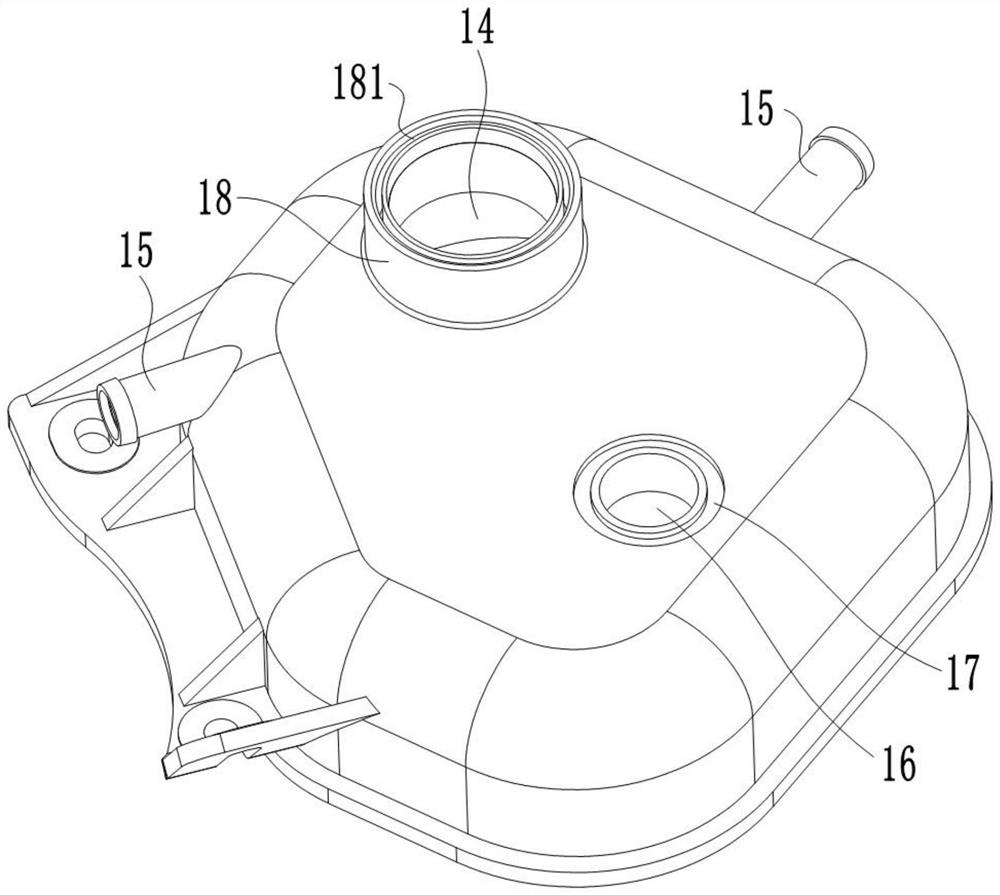

[0041] See Figure 2-Figure 5 as well as Figure 8 The expansion kettle 1 has a liquid return filter chamber 1a and a liquid outlet test chamber 1b that communicate with each other, and the expansion kettle 1 is provided with at least one water inlet 151 that communicates with the liquid return filter chamber 1a and a water inlet 151 that communicates with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com