Geopolymer-based flocculation curing agent as well as preparation method and application thereof

A coagulation and geopolymer technology, which is applied in the field of civil and construction materials, can solve the problems of inability to form self-compacting fluidized fillers and high-organic mud cannot be concentrated quickly, so as to facilitate large-scale preparation, improve flocculation and solidification effects, and promote self-compressing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The second aspect of the embodiment of the present application provides a method for preparing a geopolymer-based flocculation curing agent, comprising the following steps:

[0049] S01. Provide the components of the geopolymer-based flocculation curing agent;

[0050] S02. Mixing slag powder, silicate clinker, water glass, Fenton-like reagent and additives to obtain a geopolymer-based flocculation and curing agent.

[0051] The preparation method of the geopolymer-based flocculation-curing agent provided in the second aspect of the embodiment of the present application is simple to operate, and only needs to provide components according to the geopolymer-based flocculation-curing agent, and mix the components. The geopolymer-based flocculation curing agent is obtained, and the preparation method is simple to operate, and is beneficial to large-scale preparation.

[0052] In step S01, the components of the geopolymer-based flocculation and curing agent provided are con...

Embodiment 1

[0060] A kind of geopolymer-based flocculation curing agent and its preparation method and application

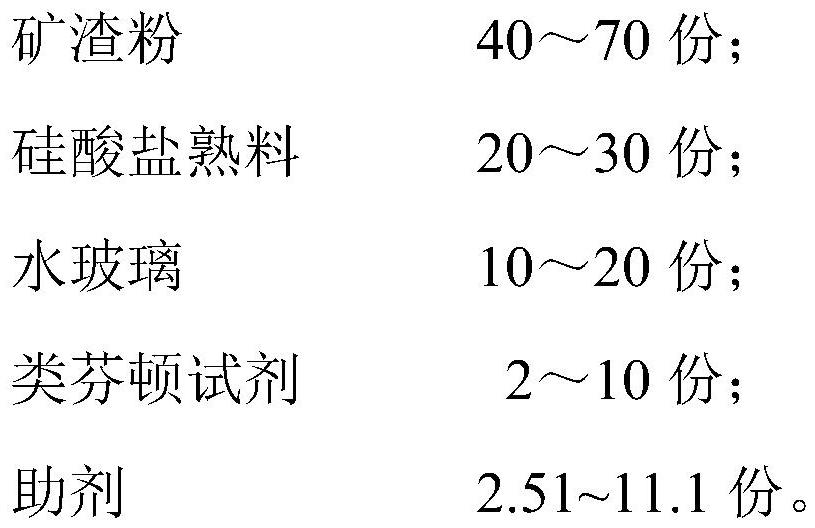

[0061] A geopolymer-based flocculation curing agent , comprising the following components by weight:

[0062]

[0063]

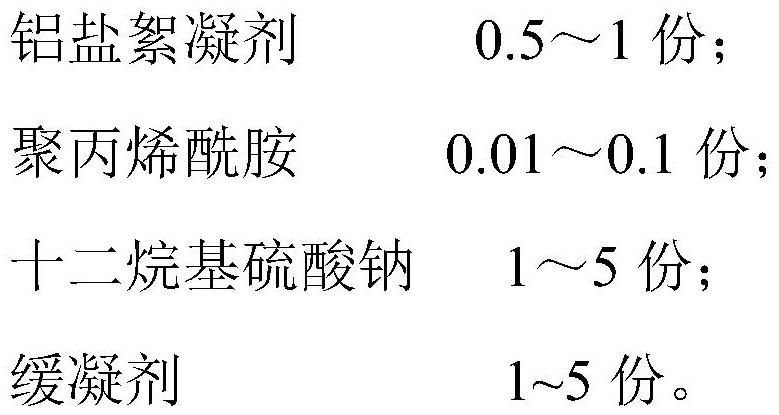

[0064] Wherein, Fenton-like is selected from the mixture of 5 parts of sodium persulfate and 5 parts of ferrous chloride; auxiliary agents include:

[0065]

[0066] A kind of preparation method of geopolymer-based flocculation curing agent , including the following steps:

[0067] Each component of the geopolymer-based flocculation solidifying agent of embodiment 1 is provided;

[0068] The slag powder, silicate clinker, water glass, Fenton-like reagent and additives are mixed to obtain a geopolymer-based flocculation curing agent; wherein, the mixing process adopts stirring and mixing, and the mixing time is 3 hours.

[0069] Application method of a geopolymer-based flocculation curing agent , including the following steps

[0070] The ...

Embodiment 2

[0075] A kind of geopolymer-based flocculation curing agent and its preparation method and application

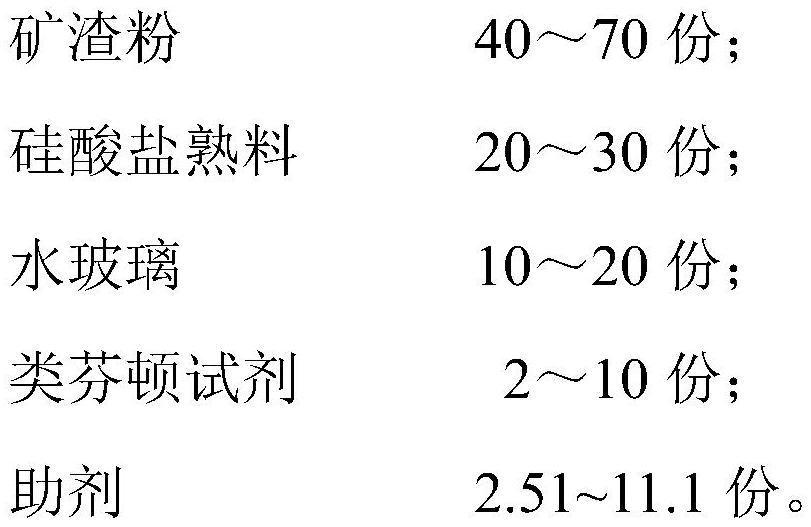

[0076] A geopolymer-based flocculation curing agent , comprising the following components by weight:

[0077]

[0078]

[0079] Wherein, Fenton-like reagent is selected from the mixture of 5 parts of sodium persulfate and 5 parts of ferrous sulfate;

[0080] Additives include:

[0081]

[0082] A kind of preparation method of geopolymer-based flocculation curing agent , including the following steps:

[0083] Each component of the geopolymer-based flocculation solidifying agent of embodiment 2 is provided;

[0084] The slag powder, silicate clinker, water glass, Fenton-like reagent and additives are mixed to obtain a geopolymer-based flocculation curing agent; wherein, the mixing process adopts stirring and mixing, and the mixing time is 4 hours.

[0085] Application method of a geopolymer-based flocculation curing agent , including the following steps

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com