Preparation method of oil-resistant self-cleaning coating

A self-cleaning coating and anti-oil technology, which is applied in coatings, rayon manufacturing, and general water supply conservation, etc., can solve problems such as corrosion, pollution, affecting the service life of materials, and affecting the appearance of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

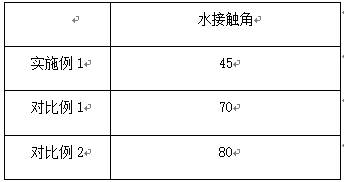

Examples

Embodiment 1

[0041] Example 1: Oil-resistant self-cleaning coating 1:

[0042] An anti-oil stain self-cleaning coating comprises: 100 parts of silicon dioxide and 200 parts of polyvinyl alcohol in parts by weight.

[0043] A preparation method of an anti-oil stain self-cleaning coating, the preparation method of the anti-oil stain self-cleaning coating mainly comprises the following steps:

[0044] (1) Dissolve cetyltrimethylammonium bromide in ethanol aqueous solution containing ammonia monohydrate, the mass ratio of cetyltrimethylammonium bromide, ammonia monohydrate, ethanol and deionized water is 35: 1:600:120, after mixing, carry out mechanical stirring, the speed is 1200r / min, the time is 2h, after the stirring is completed, quickly add tetraethyl orthosilicate, hexadecyltrimethylammonium bromide and tetraethyl orthosilicate The ester mass ratio is 1:6, react at 45°C for 24 hours, centrifuge after the reaction, then disperse the centrifuged material in deionized water, perform ultra...

Embodiment 2

[0050] Embodiment 2: Anti-oil stain self-cleaning coating 2:

[0051] An anti-oil stain self-cleaning coating comprises, in parts by weight: 200 parts of silicon dioxide and 400 parts of polyvinyl alcohol.

[0052] A preparation method of an anti-oil stain self-cleaning coating, the preparation method of the anti-oil stain self-cleaning coating mainly comprises the following steps:

[0053] (1) Dissolve cetyltrimethylammonium bromide in ethanol aqueous solution containing ammonia monohydrate, the mass ratio of cetyltrimethylammonium bromide, ammonia monohydrate, ethanol and deionized water is 35: 1:600:120, after mixing, carry out mechanical stirring, the speed is 1500r / min, the time is 3h, after the stirring is completed, quickly add tetraethyl orthosilicate, hexadecyltrimethylammonium bromide and tetraethyl orthosilicate The ester mass ratio is 1:6, react at 45°C for 24 hours, centrifuge after the reaction, disperse the centrifuged material in deionized water, and perform u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com