Pressure-sensitive adhesive composition and preparation method thereof

A technology of pressure-sensitive adhesives and compositions, applied in the direction of adhesive additives, adhesive types, ester copolymer adhesives, etc., can solve the problems of pressure-sensitive adhesives such as reduced viscosity when exposed to moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

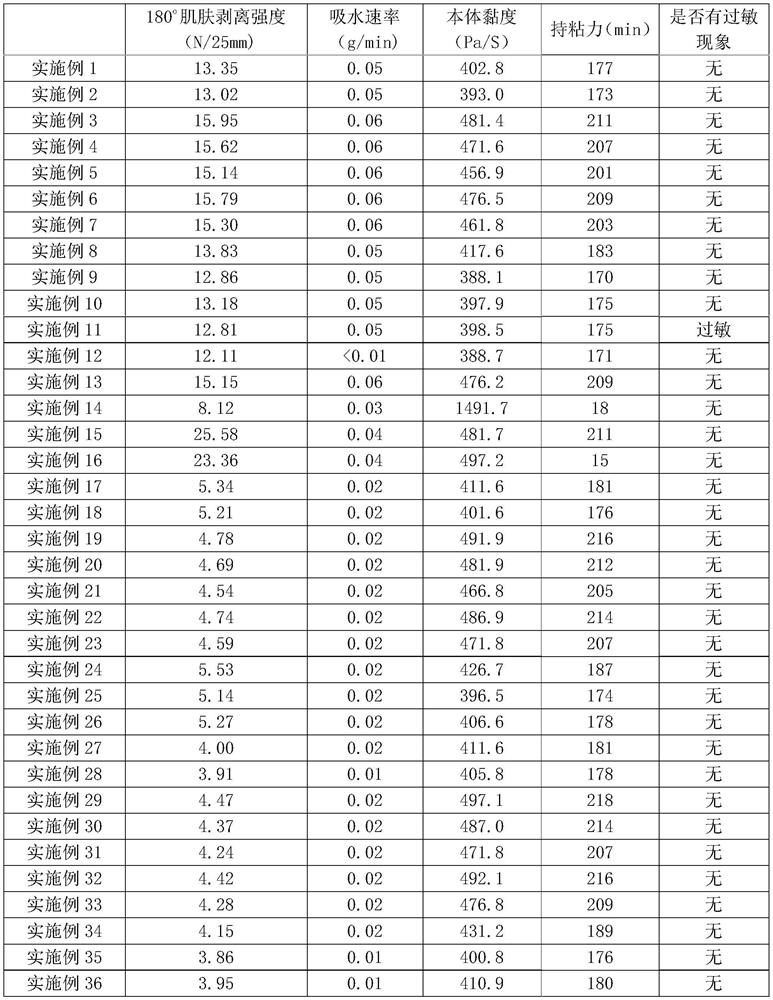

Examples

Embodiment 1

[0021] A pressure-sensitive adhesive composition, which takes the following raw materials:

[0022] Acrylate 600g;

[0023] Acrylic acid 200g;

[0024] Ethyl salicylate 90g;

[0025] Acetate starch 50g;

[0026] Sodium alginate 30g;

[0027] Anhydrous isopropanol 220g;

[0028] Aziridine 20g;

[0029] Polyethylene glycol 60g.

[0030] Preparation of pressure-sensitive adhesive composition: 1) Add anhydrous isopropanol into the reaction kettle, heat to 68-80°C, add acrylate and acrylic acid, mix well to obtain a mixed solution; 2) use the mixed solution in step 1) Add aziridine and polyethylene glycol to the mixture, and continue to heat to 90-102°C for cross-linking reaction; 3) Continue to add ethyl salicylate, acetate starch and sodium alginate, stir evenly, after the isopropanol volatilizes, The pressure-sensitive adhesive composition of Example 1 was obtained.

Embodiment 2

[0032] A pressure-sensitive adhesive composition, which takes the following raw materials:

[0033] Acrylate 620g;

[0034] Acrylic acid 300g;

[0035] Ethyl salicylate 60g;

[0036] Acetate starch 80g;

[0037] Sodium alginate 60g;

[0038] Anhydrous isopropanol 250g;

[0039] Aziridine 50g;

[0040] Polyethylene glycol 100g.

[0041] Preparation of pressure-sensitive adhesive composition: 1) Add anhydrous isopropanol into the reaction kettle, heat to 68-80°C, add acrylate and acrylic acid, mix well to obtain a mixed solution; 2) use the mixed solution in step 1) Add aziridine and polyethylene glycol to the mixture, and continue to heat to 90-102°C for cross-linking reaction; 3) Continue to add ethyl salicylate, acetate starch and sodium alginate, stir evenly, after the isopropanol volatilizes, The pressure-sensitive adhesive composition of Example 2 was obtained.

Embodiment 3

[0043] A pressure-sensitive adhesive composition, which takes the following raw materials:

[0044] Acrylate 650g;

[0045] Acrylic acid 280g;

[0046] Ethyl salicylate 80g;

[0047] Acetate starch 60g;

[0048] Sodium alginate 50g;

[0049] Anhydrous isopropanol 270g;

[0050] Aziridine 40g;

[0051] Polyethylene glycol 80g.

[0052] Preparation of pressure-sensitive adhesive composition: 1) Add anhydrous isopropanol into the reaction kettle, heat to 68-80°C, add acrylate and acrylic acid, mix well to obtain a mixed solution; 2) use the mixed solution in step 1) Add aziridine and polyethylene glycol to the mixture, and continue to heat to 90-102°C for cross-linking reaction; 3) Continue to add ethyl salicylate, acetate starch and sodium alginate, stir evenly, after the isopropanol volatilizes, The pressure-sensitive adhesive composition of Example 3 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com