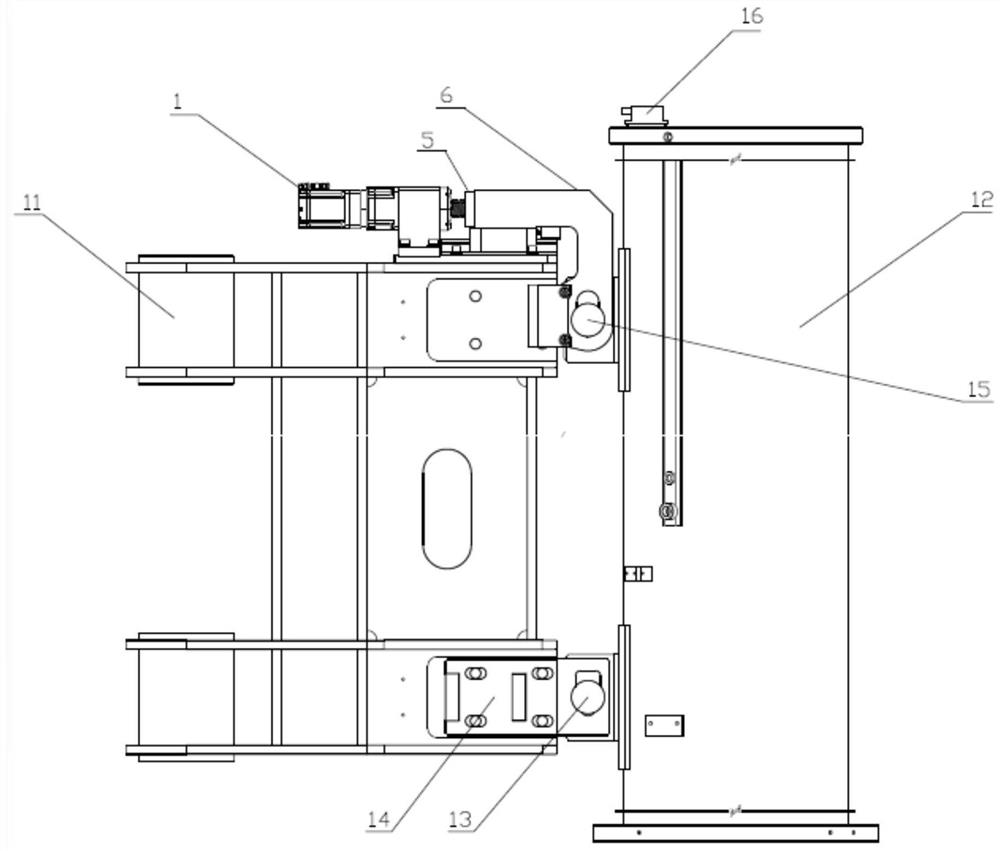

Leveling mechanism and leveling method for auxiliary furnace chamber of single crystal furnace

A technology of leveling mechanism and auxiliary furnace chamber, which is applied in the directions of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of long time consumption, complicated operation, inability to solve the inclination of the auxiliary furnace chamber, etc., and achieves less time consumption. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

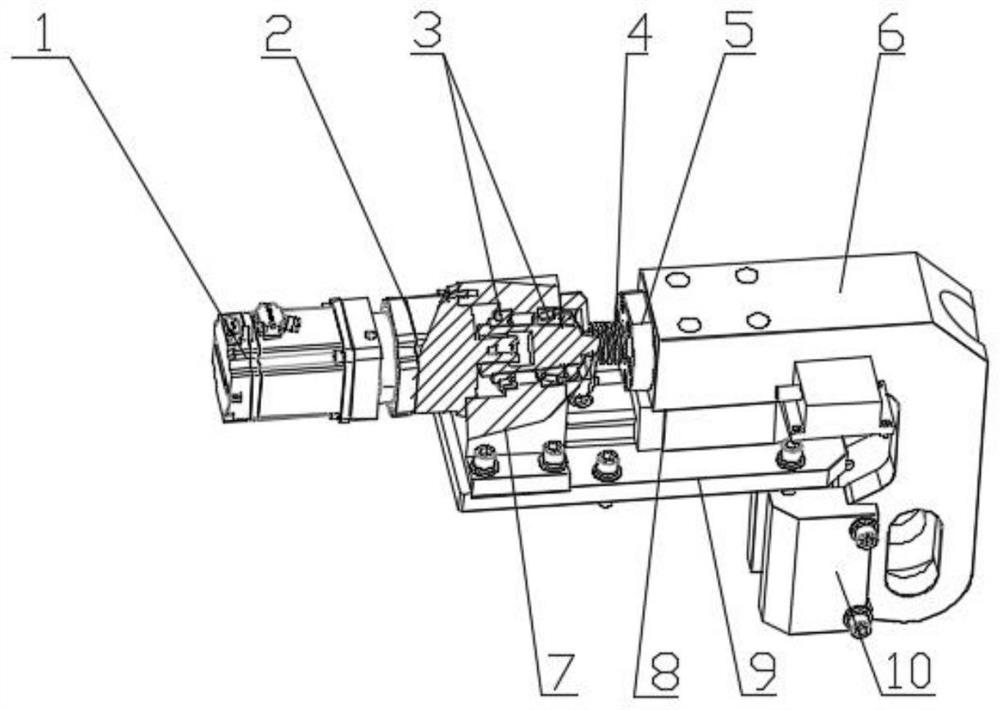

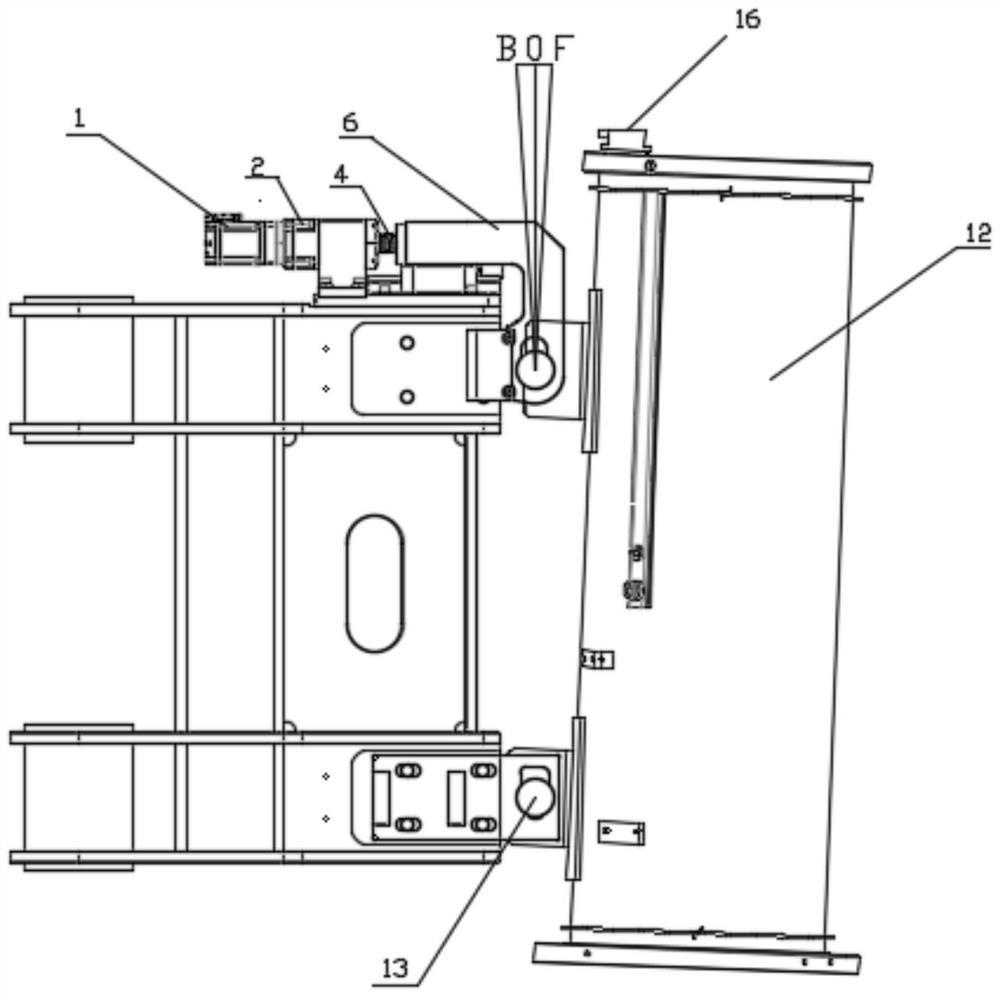

[0034] Implementation example 1: When the auxiliary furnace chamber is raised under the state of carrying the ingot

[0035] Such as image 3 As shown, due to the existence of structural rigidity and bearing gaps, etc., the auxiliary furnace chamber 12 moves outward (i.e. image 3 F side) tilt; the horizontal monitoring component 16 monitors the angle change, and feeds back to the control component; the control component outputs a correction command to the motor 1, at this time, the motor 1 rotates forward, and after being decelerated by the reducer 2, it drives the screw mandrel 4 to rotate clockwise. Pull the tension arm 6 to move inwardly, with the connecting block at the lower end of the auxiliary furnace chamber 12 as the fulcrum, the tension arm 6 drives the upper connecting block of the auxiliary furnace chamber 12 to move closer to the motor side, thereby correcting the inclination angle. Realize the leveling of the auxiliary furnace chamber and ensure the vertical st...

Embodiment 2

[0036] Implementation example 2: When the auxiliary chamber descends under no-load state after taking the rod:

[0037] Such as image 3 As shown, the auxiliary furnace chamber 12 moves to the inside (i.e. image 3 B side) tilt, the level monitoring component 16 monitors the angle change, and feeds back to the control component; the control component outputs a correction command to the motor 1, at this time, the motor 1 reverses, and after being decelerated by the reducer 2, the screw rod 4 is driven to rotate counterclockwise. Pull the tension arm 6 to move outwards, with the lower connecting block of the auxiliary furnace chamber 12 as the fulcrum, the tension arm 6 drives the upper connecting block of the auxiliary furnace chamber 12 away from the motor side, thereby correcting the inclination angle. Realize the leveling of the auxiliary furnace chamber and ensure the vertical state of the auxiliary furnace chamber, that is image 3 The O position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com